Tuyere duct system used for side window defrosting

An air duct and tuyere technology, applied in the field of tuyere air duct system, can solve the problems of mutual interference of other components and poor defrosting effect, and achieve the effect of air duct layout difficulty and low cost, convenient layout and optimization of defrost tuyere.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

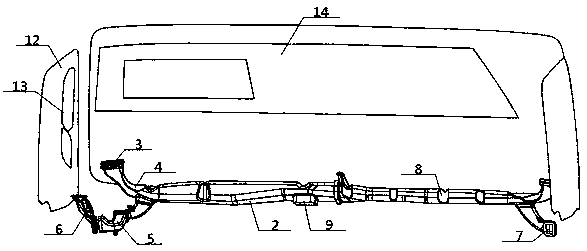

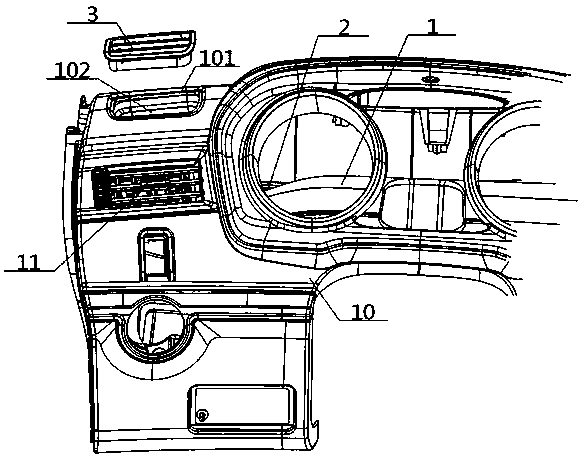

[0047] see Figure 1 to Figure 4 , an air outlet duct system for side window defrosting, comprising a defrosting air duct 2 and defrosting air ducts 3 arranged at both ends thereof, and the middle part of the defrosting air duct 2 communicates with an air-conditioning air inlet 9; The frost air duct 2 is arranged in the dashboard 10 of the cab, and below the defrosting air duct 2 is a face blowing air duct 1 separated from each other. The defrosting air outlets 3 are separated from each other, and the defrosting air outlets 3 are arranged near the cab side window 12 . Preferably, the face air outlet 11 is located below the defroster air outlet 3 .

Embodiment 2

[0049] Basic content is the same as embodiment 1, the difference is:

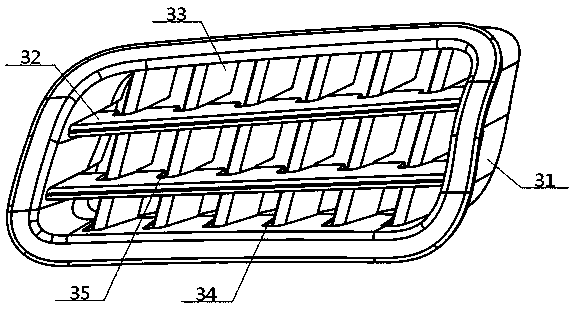

[0050] The outer circumference of the defrosting air outlet 3 is engaged with the inner groove cavity 102 of the air outlet groove 101 , and the air outlet groove 101 is arranged in the dashboard 10 of the cab. The defrosting tuyere 3 includes an outer seat 31 of the tuyere and a fixed plate 32 and a guide plate 33 arranged inside thereof. The outer circumference of the outer seat 31 of the tuyere is inserted into the inner groove cavity 102 of the air outlet groove 101, and the fixed The quantity of the plate 32 is at least one, and the quantity of the guide plate 33 is at least two; The upper and lower inner walls of the outer seat 31 are rotatably connected, and the middle part of the guide plate 33 is rotatably connected with the middle part of the fixing plate 32 . Preferably, the upper and lower inner walls of the outer seat 31 of the tuyere are provided with an outer seat arc groove 34, and the oute...

Embodiment 3

[0052] Basic content is the same as embodiment 1, the difference is:

[0053] The two ends of the defrosting air duct 2 are respectively connected to the bottom of the upward turning air duct 4, and the top of the upward turning air duct 4 is connected to the bottom of the defrosting tuyere 3, and the defrosting air duct 2 is close to the top. The part where the turning-out air duct 4 is connected to the inner end of the side-extending air duct 5, and the outer end of the side-extending air duct 5 is connected to the door defrosting opening 7, and the door defrosting opening 7 is close to the cab side window 12 set up. Preferably, the outer end of the side-extending air duct 5 is connected with the bottom end of the upturn door air duct 6, and the top end of the upturn door air duct 6 is connected with the door defrosting opening 7, and the defrosting tuyere 3, the door defrosting The air outlet directions of the ports 7 are all towards the side window glass 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com