Corrugated steel pipe-steel sandwich layer composite pipe concrete combined component

A technology of corrugated steel pipes and combined components, applied in the fields of construction and bridges, can solve the problems of outer steel pipe buckling, poor corrosion resistance, weak anti-collision and impact resistance, etc., achieve compact structure, improve mechanical properties, and solve corrosion resistance poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

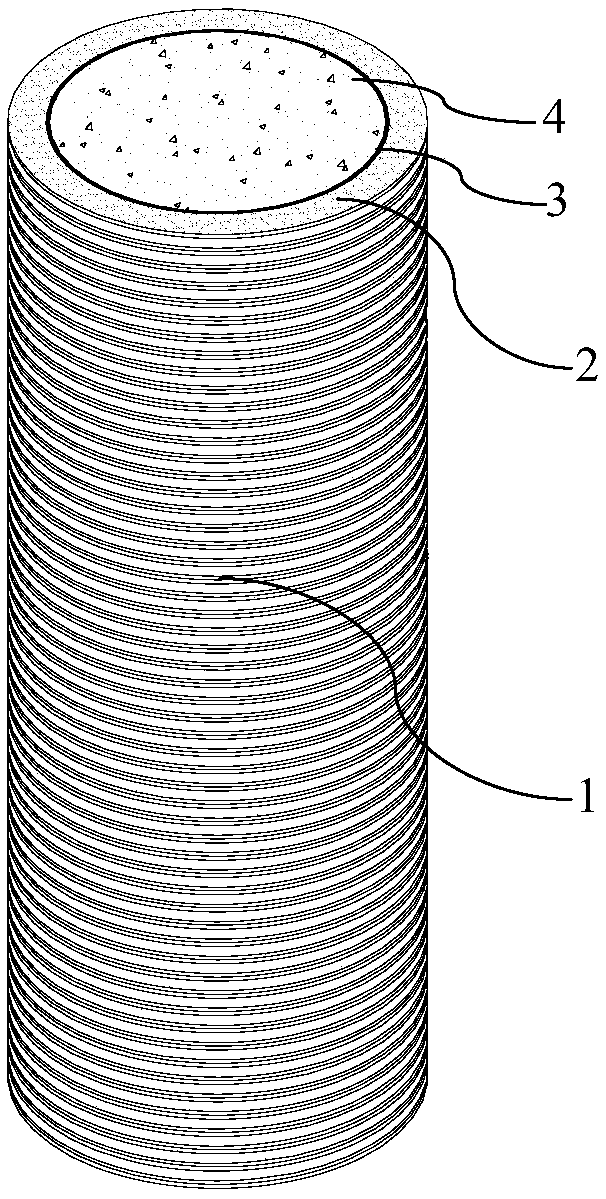

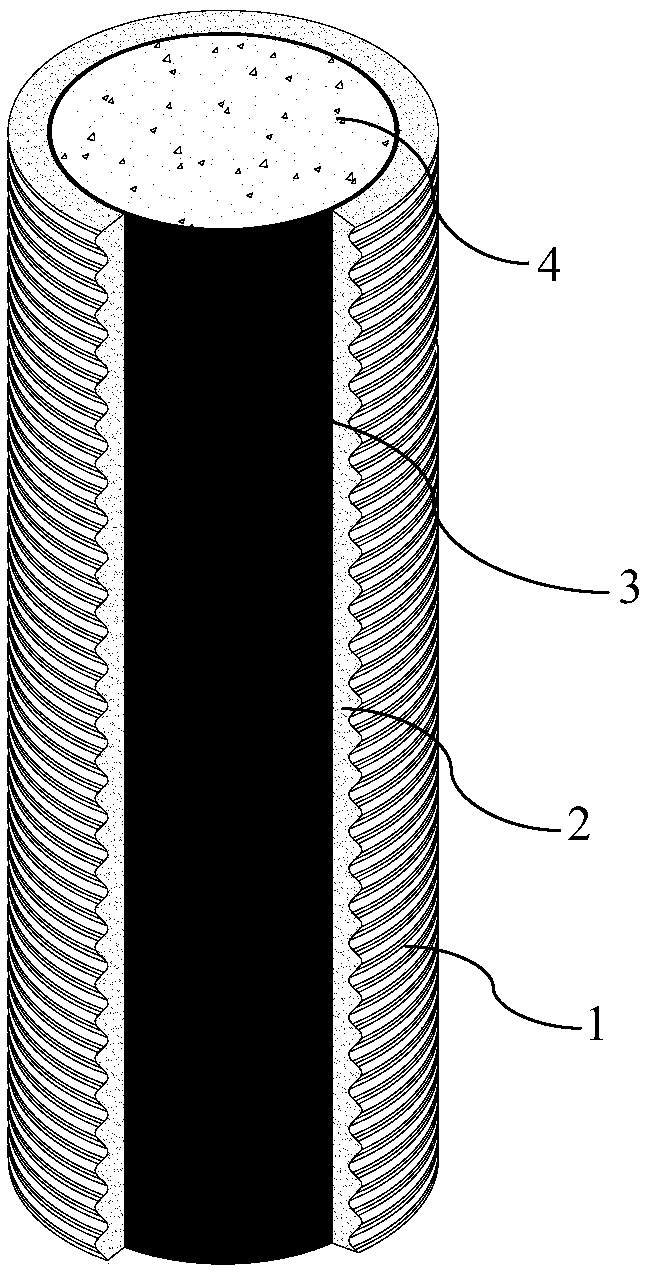

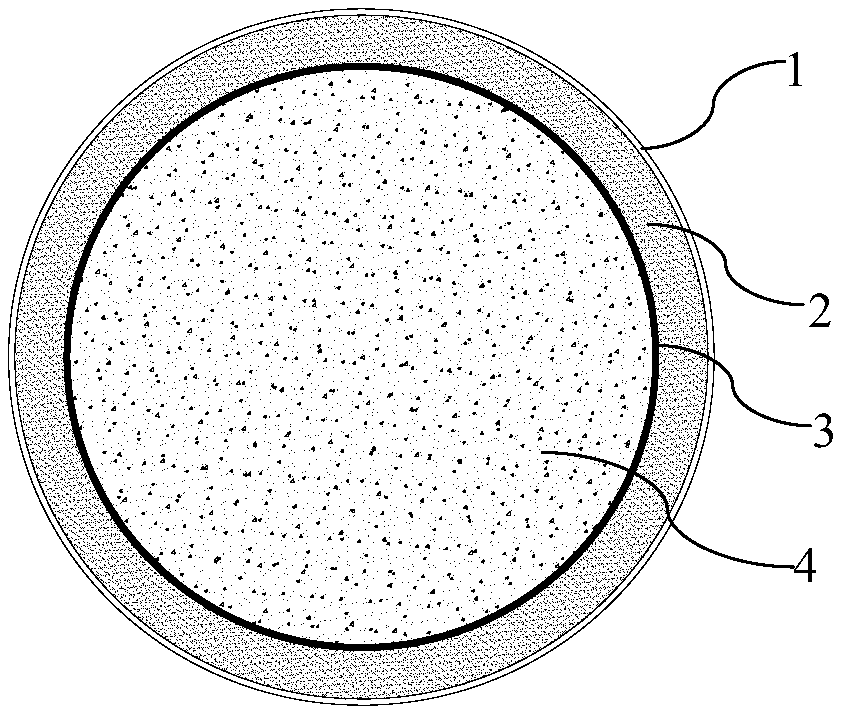

[0021] Specific implementation mode one: as Figure 1~3 As shown, the corrugated steel pipe-steel sandwich composite pipe-concrete composite member of this embodiment includes a corrugated steel pipe 1, interlayer filler 2, steel pipe 3 and core concrete 4, the steel pipe 3 is located in the corrugated steel pipe 1 and the two are coaxially arranged, and the interlayer filling The material 2 is filled between the corrugated steel pipe 1 and the steel pipe 3, the corrugated steel pipe 1, the interlayer filler 2 and the steel pipe 3 form a corrugated steel pipe-steel sandwich composite pipe, and the core concrete 4 is filled in the steel pipe 3.

[0022] The production of corrugated steel pipe-steel sandwich composite pipe-concrete composite members mainly includes the following steps:

[0023] Step 1. Preparation of corrugated steel pipe 1: Taking galvanized spiral corrugated steel pipe as an example, the ordinary steel plate is hot-dip galvanized, mechanically rolled, spirally...

specific Embodiment approach 2

[0028] Embodiment 2: In this embodiment, the corrugated steel pipe 1 is a galvanized corrugated steel pipe, and the corrugated steel pipe 1 is a spiral corrugated steel pipe, an annular corrugated steel pipe or splicing of two half-pipes. With such a design, the corrugated steel pipe directly in contact with the external environment has better corrosion resistance under the protection of the galvanized layer, and the interlayer filling material has a dense structure and good anti-seepage and corrosion resistance, realizing double protection for the inner steel pipe. The problem of poor corrosion resistance of steel pipe concrete is well solved. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: In this embodiment, the corrugated steel pipe 1 is formed by sequentially connecting multiple steel pipes with bolts through flanges. In this design, in engineering application, the corrugated steel pipe-steel sandwich composite pipe is prefabricated in the factory, and the corrugated steel pipe 1 and steel pipe 3 inside the composite pipe are reserved for a certain length, and are welded or flanged according to the actual situation after transportation to the site. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com