Pump gate and control system

A control system and controller technology, applied in water conservancy projects, sea area projects, coastline protection, etc., to achieve the effects of small footprint, high hydraulic efficiency, and enhanced drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

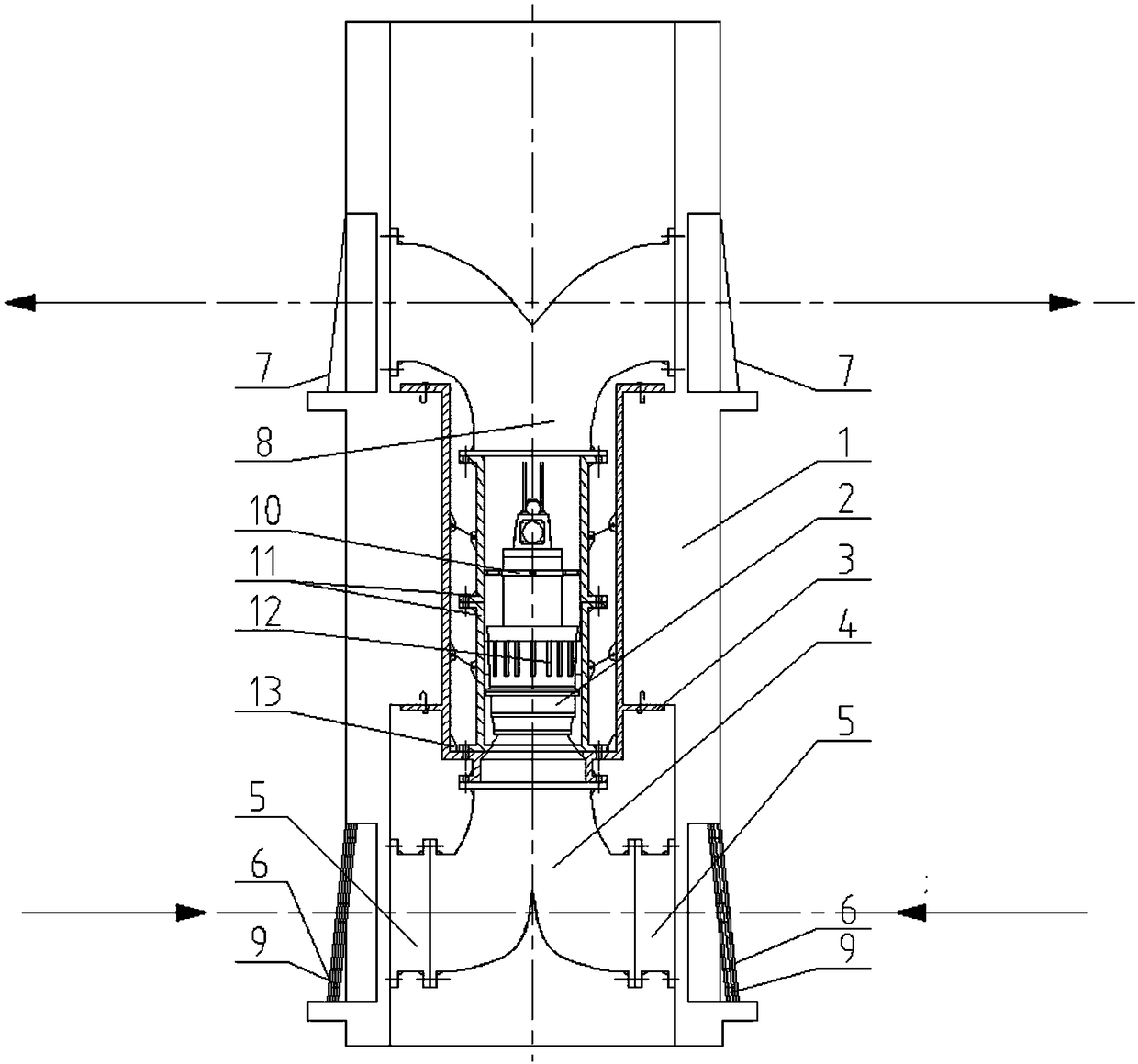

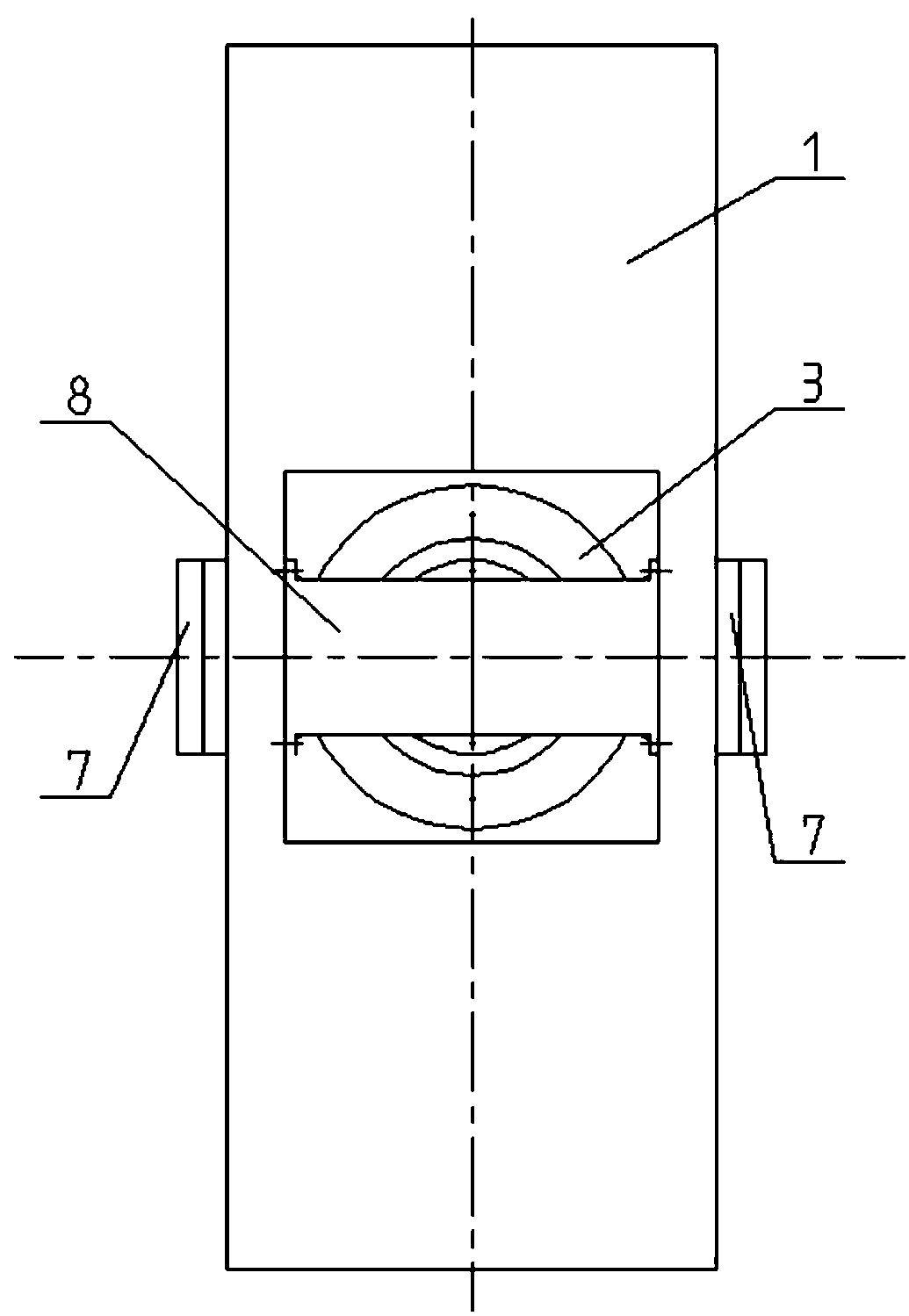

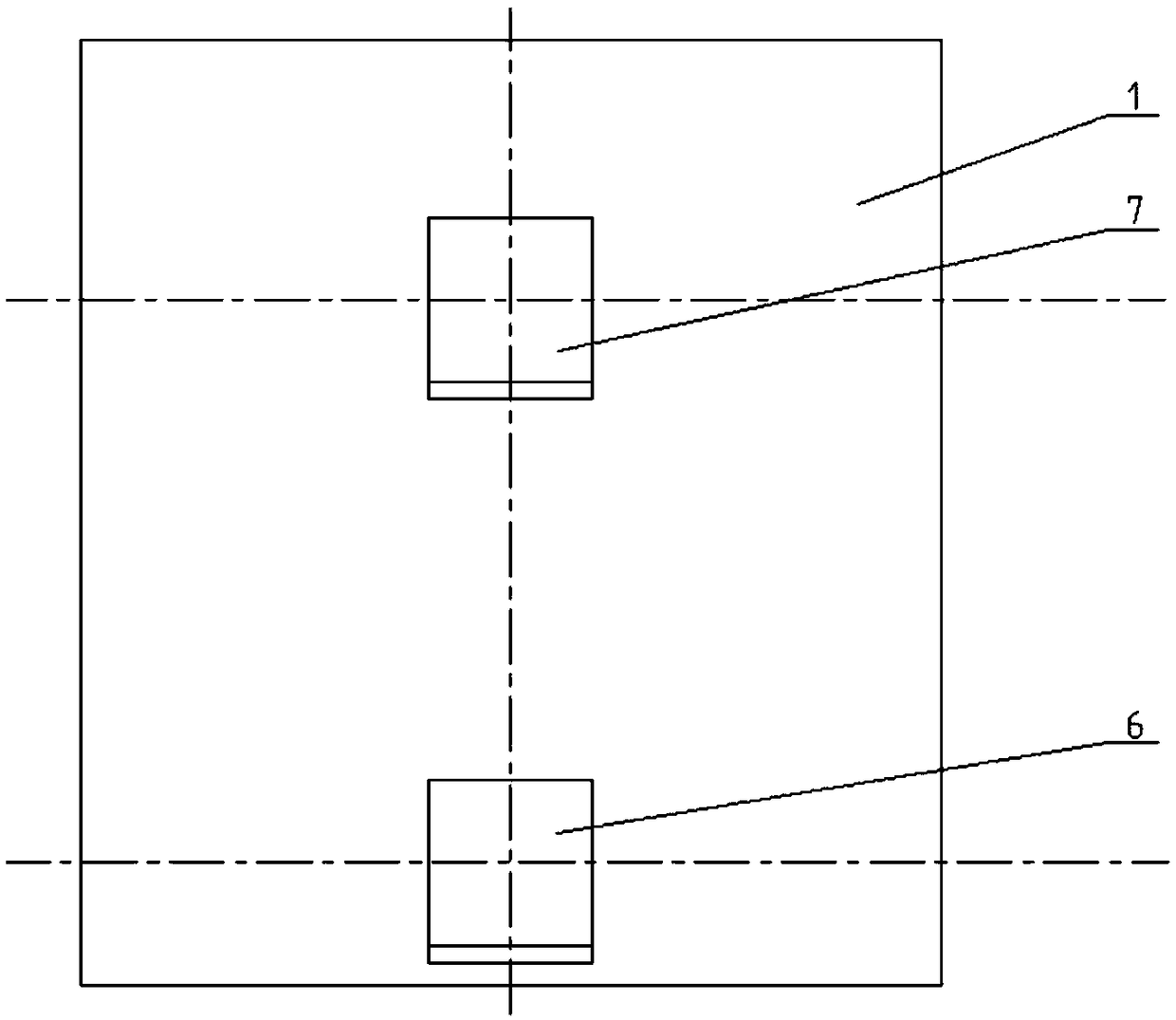

[0055] figure 1 , 2 Shown in and 3 is an embodiment of the pump gate of the present invention. The pump gate includes a gate plate 1, a sleeve 3, a pump barrel 11, a vertical axial flow pump 2, a bidirectional inlet flow channel 4, and an outlet bidirectional Runner 8;

[0056] The sleeve 3 is installed in the gate 1;

[0057] The pump barrel 11 is installed in the sleeve 3;

[0058] The vertical axial flow pump 2 is installed in the pump cylinder 11;

[0059] The two-way inlet channel 4 is located below the inside of the gate 1, one end of the two-way inlet channel 4 is connected to the water inlet of the vertical axial flow pump 2, and the other end is respectively connected to the water inlets on both sides of the gate 1, the gate The water inlets on both sides of the plate 1 are respectively equipped with imported two-way valves 6;

[0060] The outlet two-way flow channel 8 is located above the inside of the gate 1, and one end of the outlet two-way flow channel 8 is co...

Embodiment 2

[0080] A control system for a pump gate, comprising the pump gate described in Embodiment 1 and a controller;

[0081] The controller is respectively connected with the flashboard 1, the vertical axial flow pump 2, the inlet two-way flap door 6 and the outlet two-way flap door 7.

[0082] When the water enters from the left side and the water comes out from the right side: the controller controls the gate 1 to close, the left inlet two-way flap door 6 and the right outlet two-way flap door 7 open, the right inlet two-way flap door 6 and the left outlet two-way flap door 7 is in the closed state, and the vertical axial flow pump 2 is started to run in the forward direction. At this time, water enters from the left side and water exits from the right side.

[0083] When water enters from the right side and water exits from the left side: the controller controls the gate 1 to close, the right inlet bidirectional flap door 6 and the left outlet bidirectional flap door 7 open, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com