Automatic barring device and control method

A technology of a turning device and a control method, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as high labor intensity, hidden dangers of personal and equipment safety, and prone to danger and mistakes, so as to reduce labor intensity, The effect of improving personal and equipment safety, avoiding mistakes and dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In view of this, the core of the present invention is to provide an automatic cranking device, which can not only reduce labor intensity, save time and effort, but also avoid errors and dangers caused by on-site operations, thereby effectively improving personal and equipment safety.

[0035] Another core of the present invention is to provide an automatic cranking control method.

[0036] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

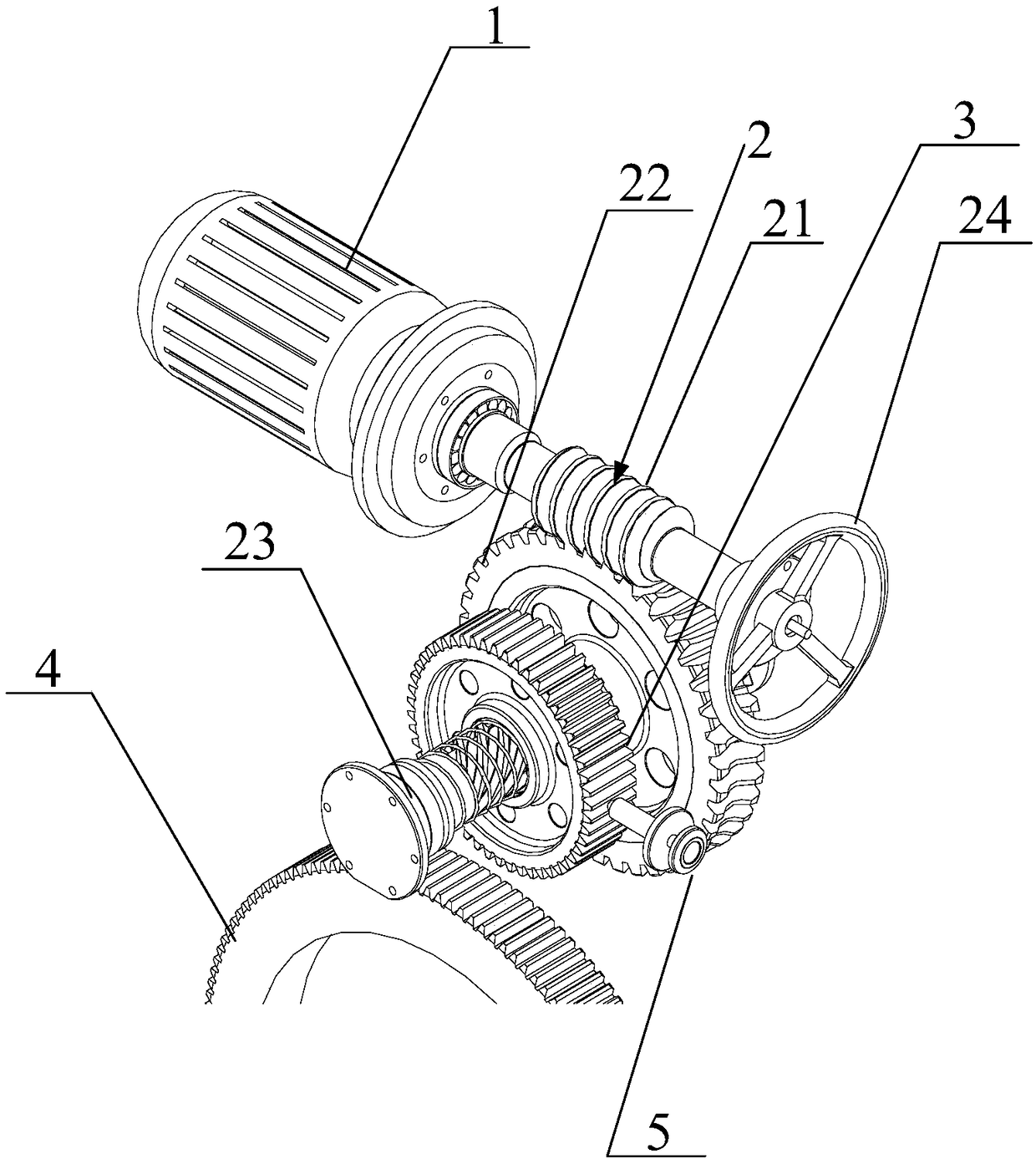

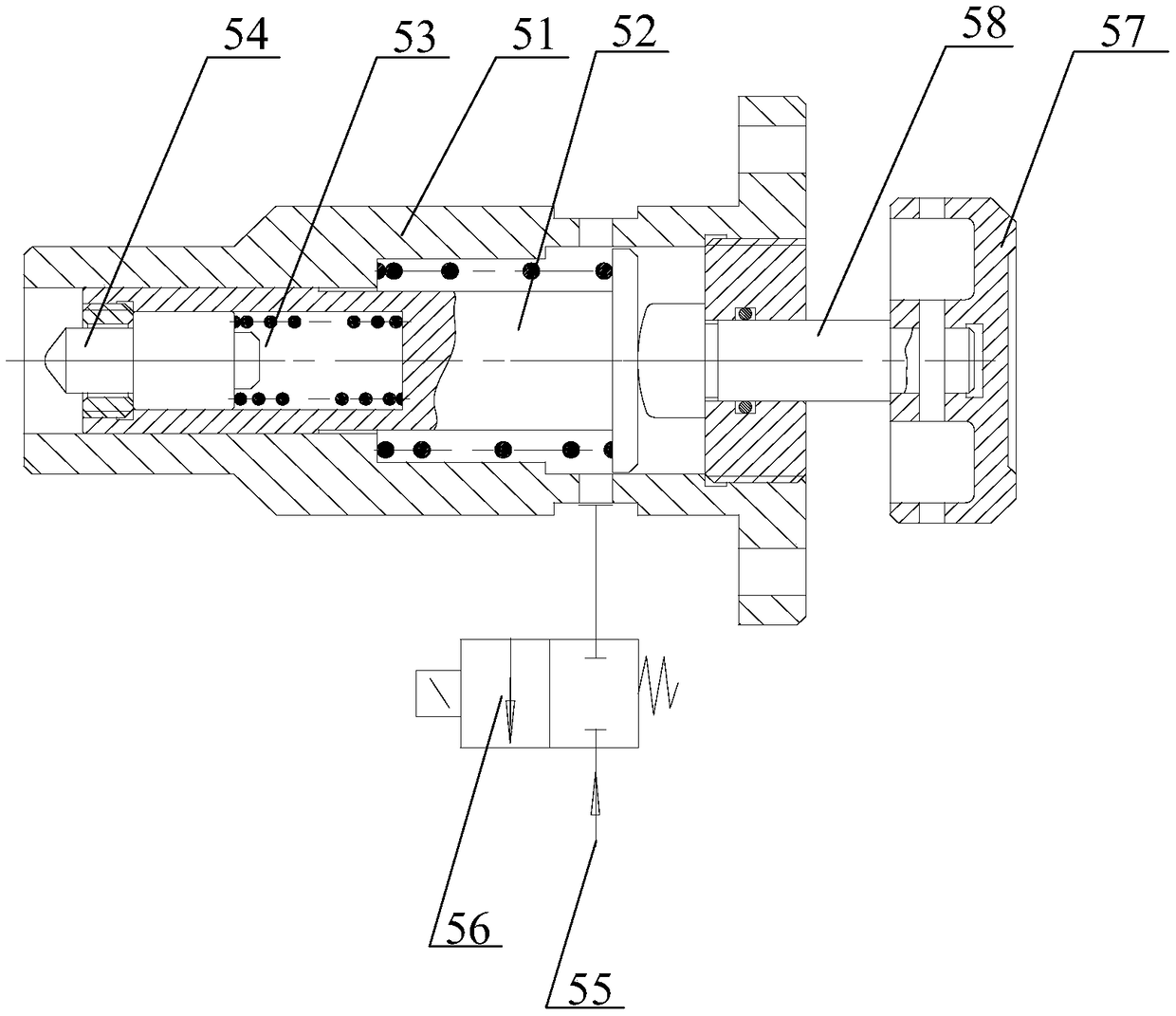

[0037] The automatic barring device disclosed in the embodiment of the present invention includes a barring drive motor 1, and a worm gear mechanism 2 for connecting with the barring drive motor 1. The worm gear mechanism 2 is sleeved with a lead screw, and There is a moving gear 3 for meshing with the turning gear 4, and the turning gear 4 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com