A frame strength test device based on a center pin loading mechanism

A technology of loading mechanism and strength test, applied in the direction of railway vehicle testing, etc., can solve the problems of asynchronization of the force state of the lateral stopper, unmonitoring of the balance of the force, and the large space occupied by the loading device, so as to avoid blocking interference, Easy assembly operation and maintenance, compact layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

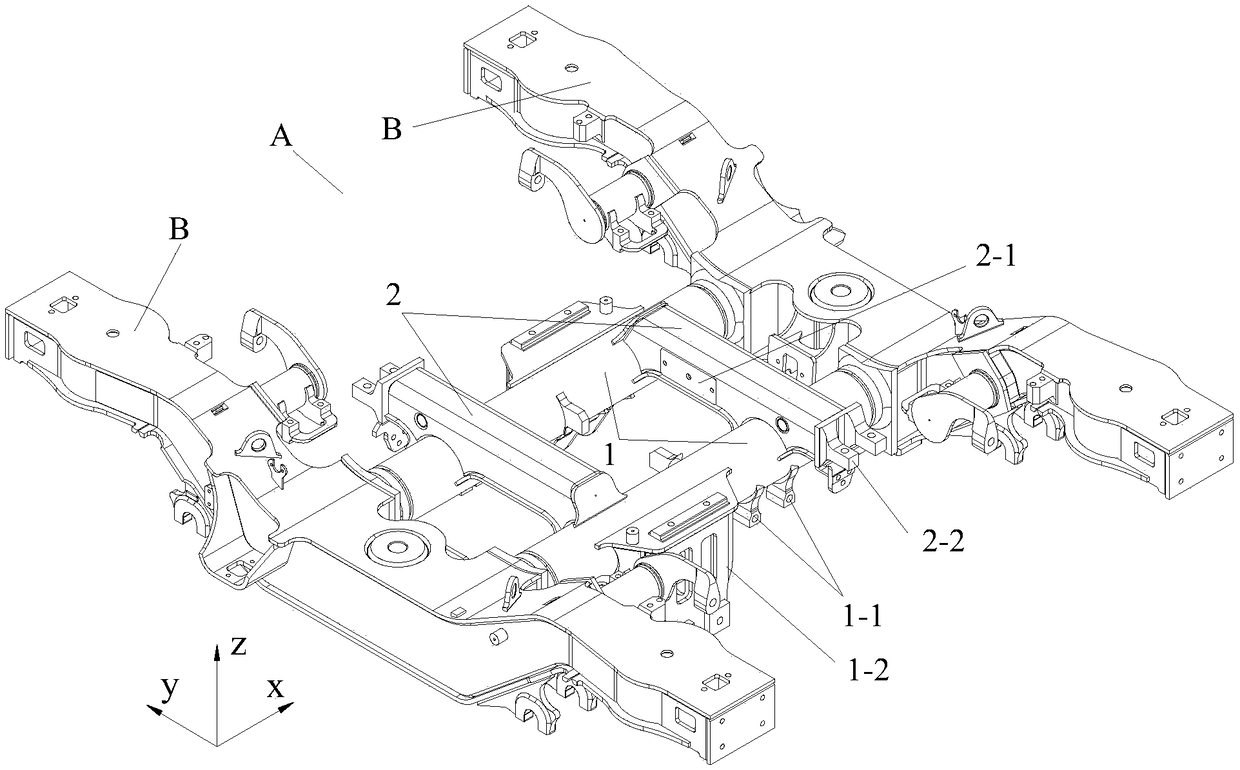

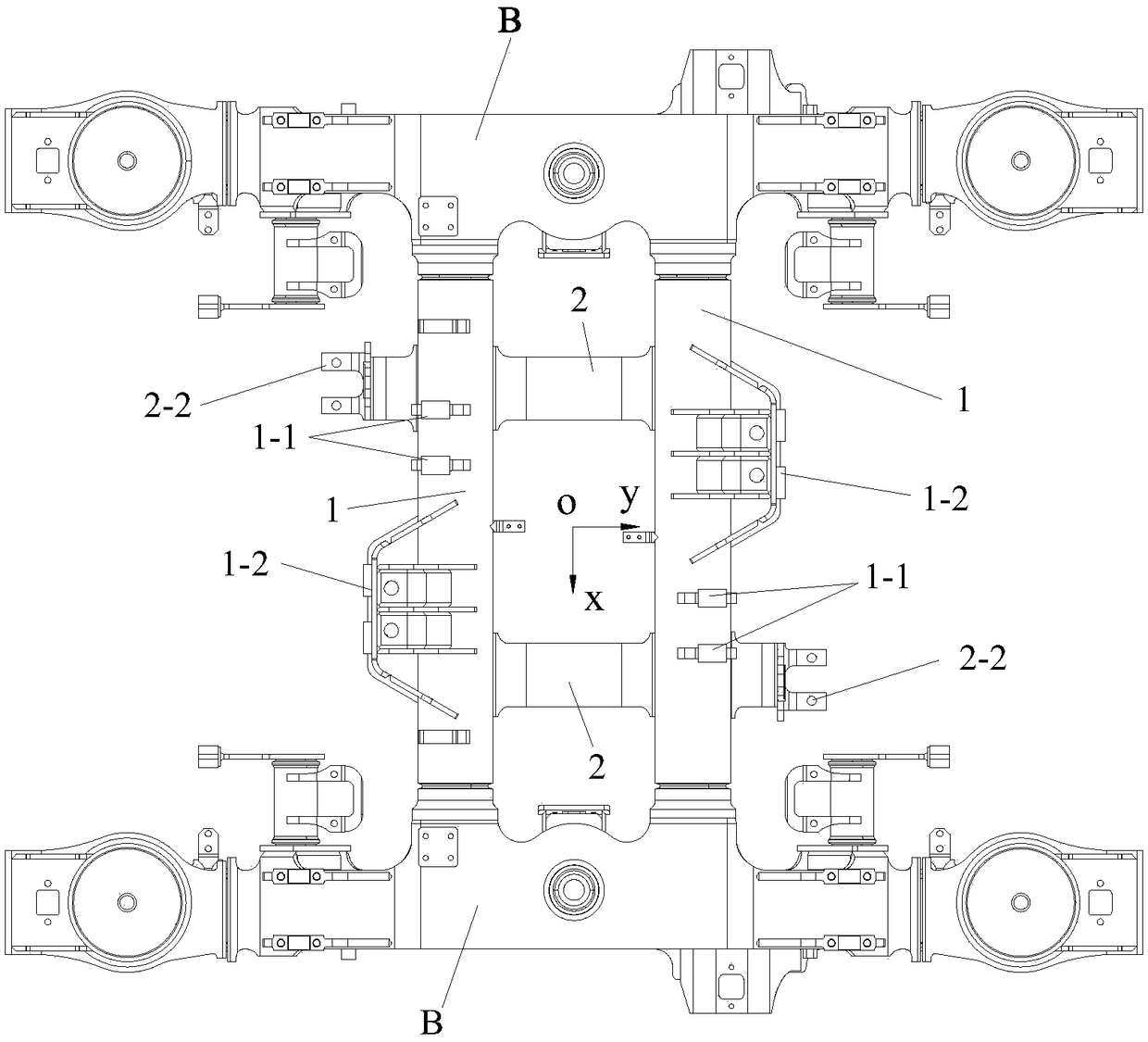

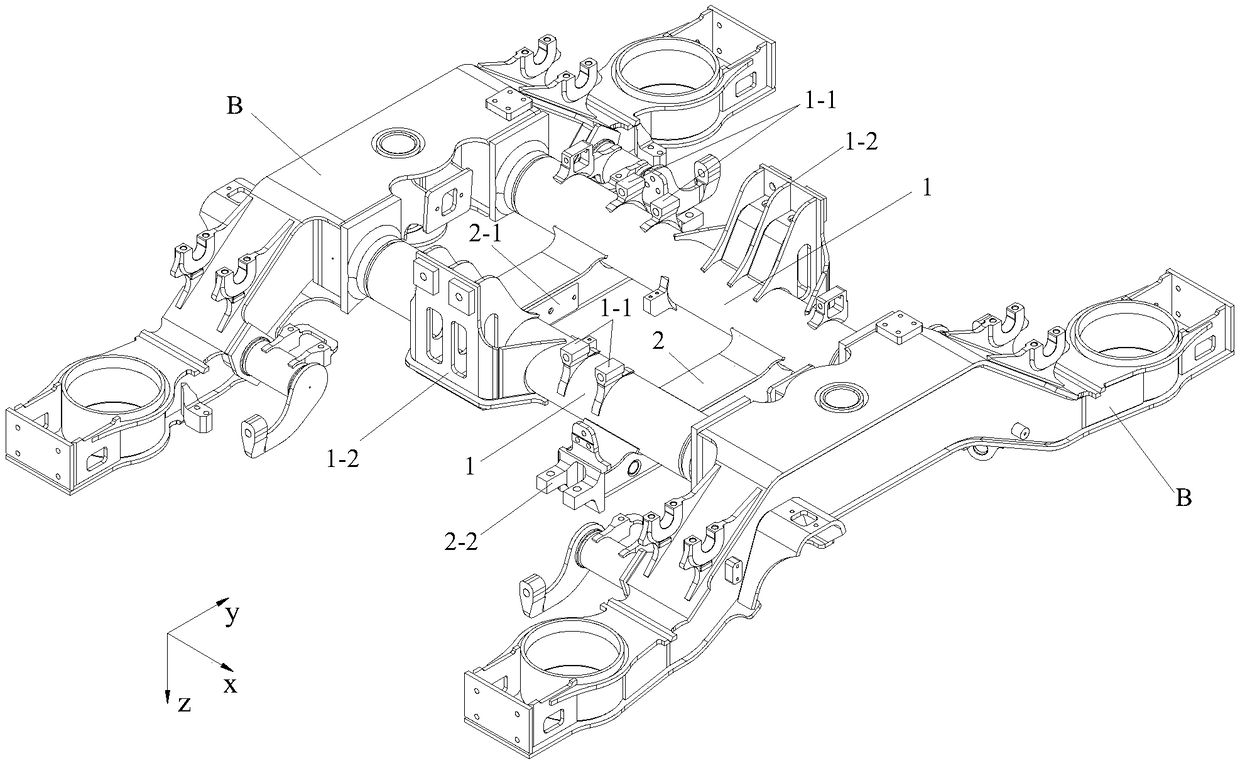

[0044] Such as Figure 4 to Figure 18 As shown, the frame strength test device based on the central pin loading mechanism of the present invention includes a simulated central pin loading mechanism, a universal spherical support 3, a lateral stop spherical support 8, two stop seat rubber pads 9, two measuring Force type traction rod 10, two lateral force loading actuating mechanisms 11 and longitudinal reaction rod 12, the simulated center pin loading mechanism includes tubular core barrel 4, force measuring traction rod seat 5, lateral force symmetrical slope loading seat 6 , the reaction rod loads the hinge shaft seat 7 and the lateral stopper spherical bearing 8; the lower end of the universal spherical bearing 3 is fixedly connected with the ground, the lower end of the core barrel 4 is fixedly connected with the universal spherical bearing 3, and its axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com