Automatic sampling control method for coal quality detection

An automatic sampling and control method technology, applied in the direction of sampling devices, etc., can solve the problems of personal injury, difficulty in deep coal sampling, and low sampling efficiency, so as to increase the sampling range and sampling randomness, simple structure, The effect of improving sampling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

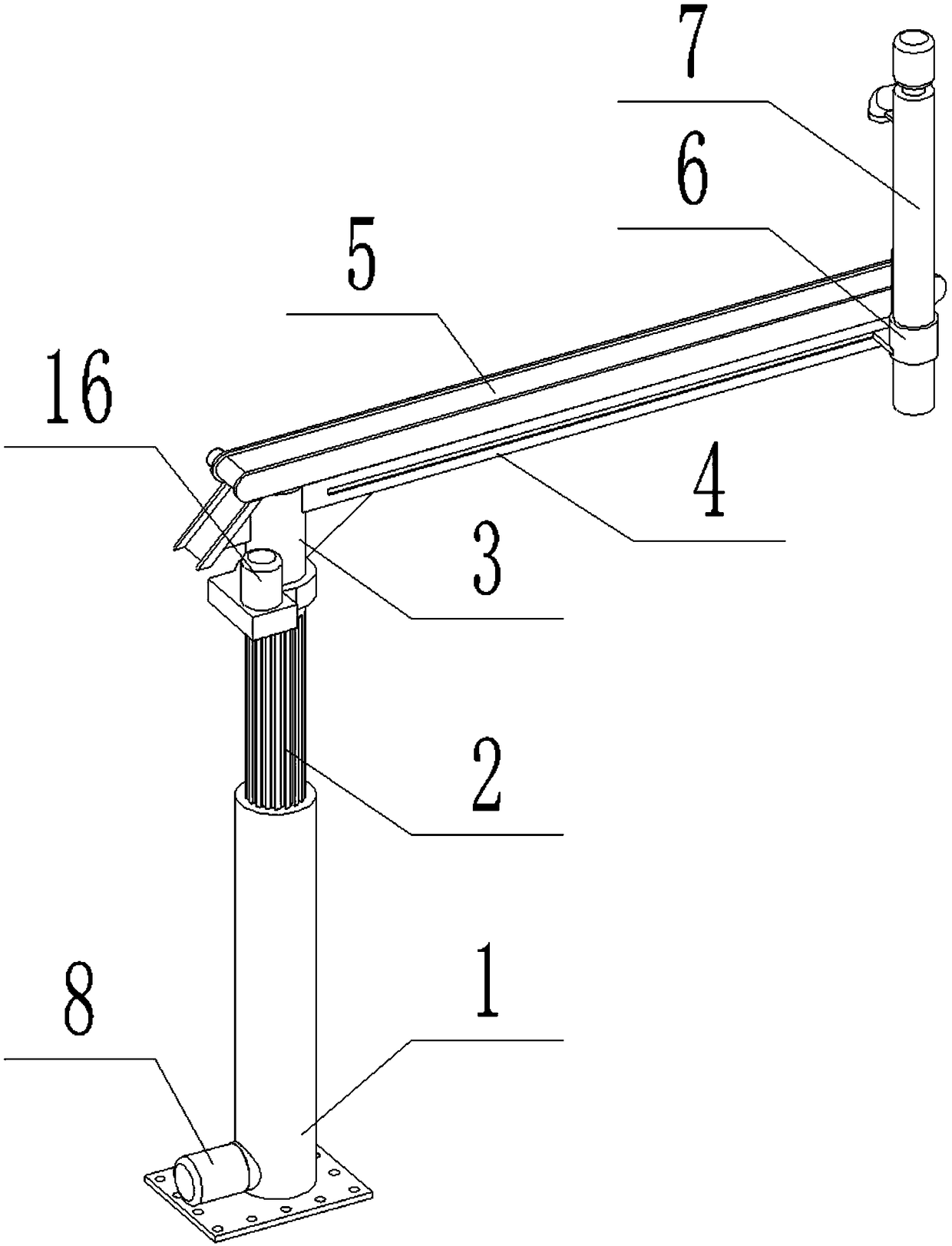

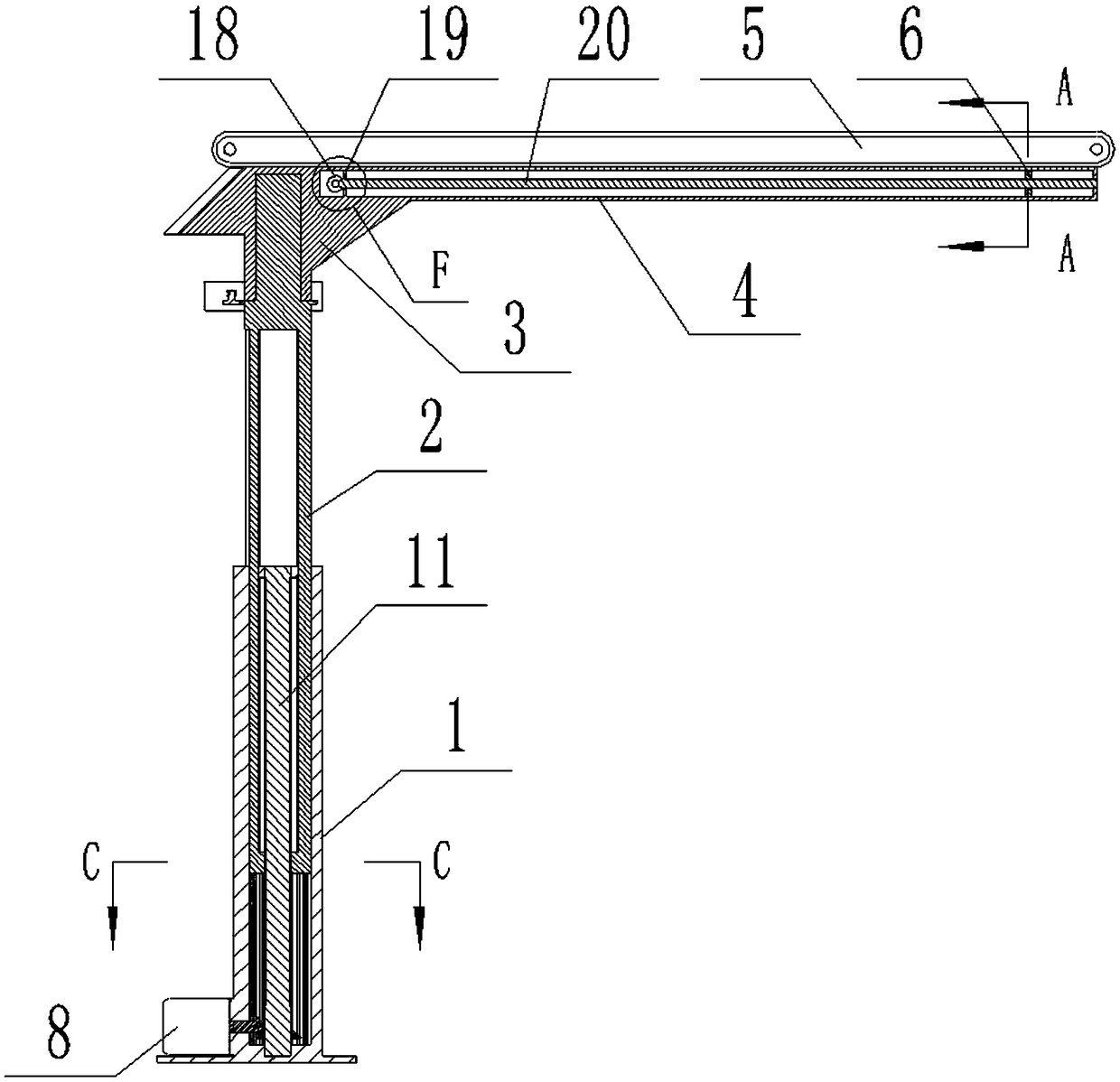

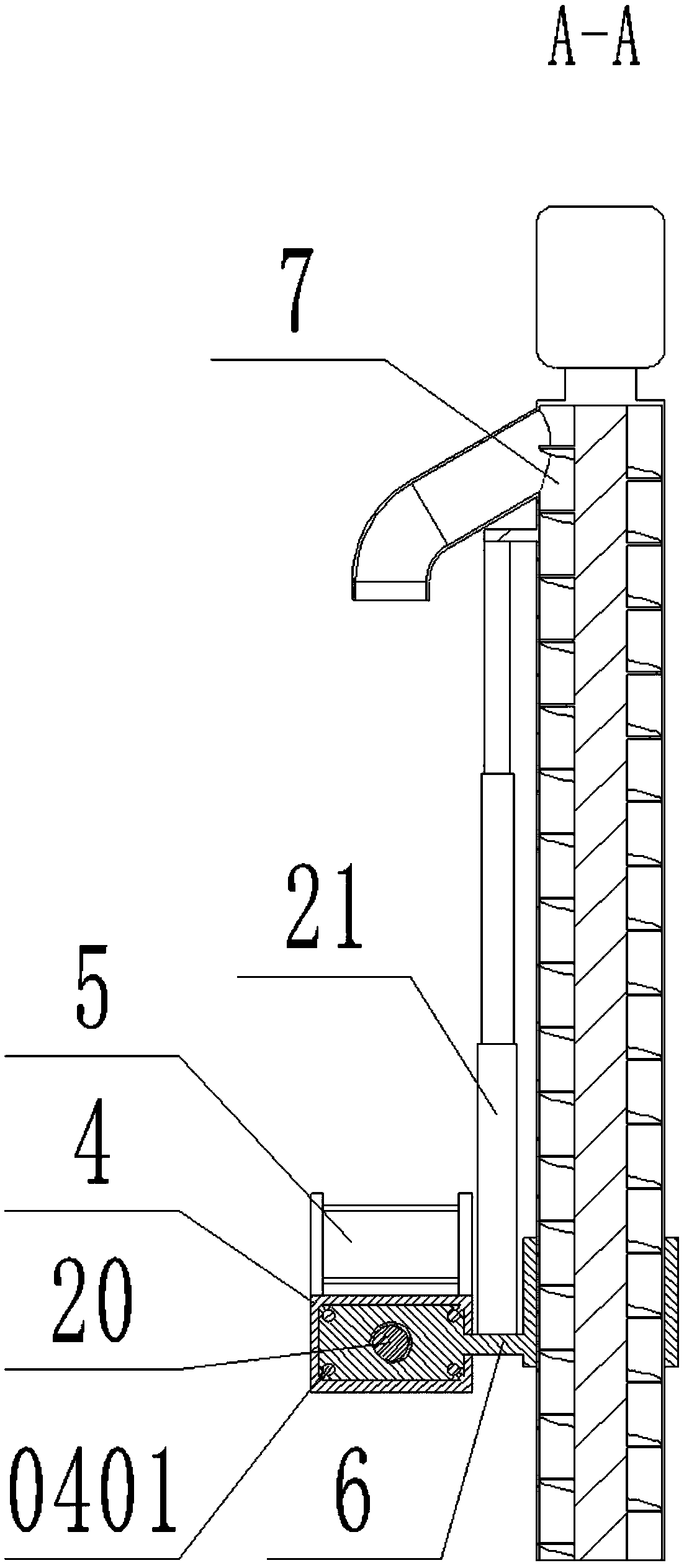

[0037] The present invention provides an automatic sampling control method for coal quality detection. The automatic sampling control method is realized based on an automatic sampling device, as shown in the attached figure 1 to attach Figure 8 Shown:

[0038]The automatic sampling equipment includes: base 1, lifting column 2, spline groove 0201, outer ring gear 0202, rotating seat 3, beam 4, circular rail 0401, conveyor belt 5, sliding pallet 6, spiral sampler 7, lifting motor 8 , lifting driving bevel gear 9, lifting driven shaft bevel gear 10, lifting screw 11, steering driving gear 12, steering driven pulley 13, conveyor belt 14, steering driving pulley 15, steering motor 16, slipping motor 17, Sliding driving bevel gear 18, sliding driven bevel gear 19, sliding screw 20 and electro-hydraulic push rod 21; a set of lifting motor 8 is fixedly connected to the left side of base 1; There is a set of lifting active bevel gears 9; the upper part of the base 1 is slidingly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com