Perovskite nano film prepared based on 'hot air method', preparation method thereof and application in solar battery

A nano-film and perovskite technology, applied in the field of solar cells, can solve the problems of rapid preparation of perovskite films, etc., and achieve the effects of improving the surface, good controllability, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

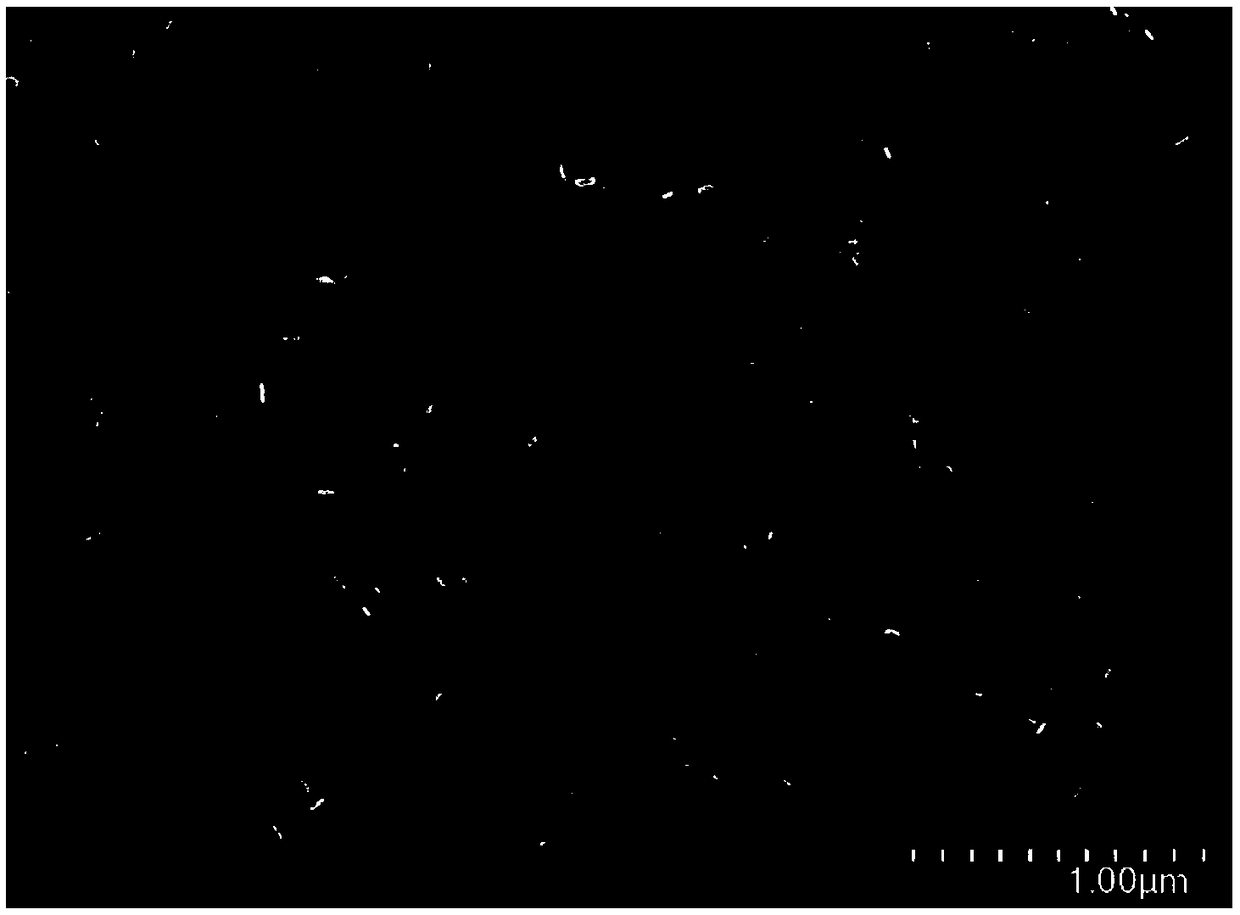

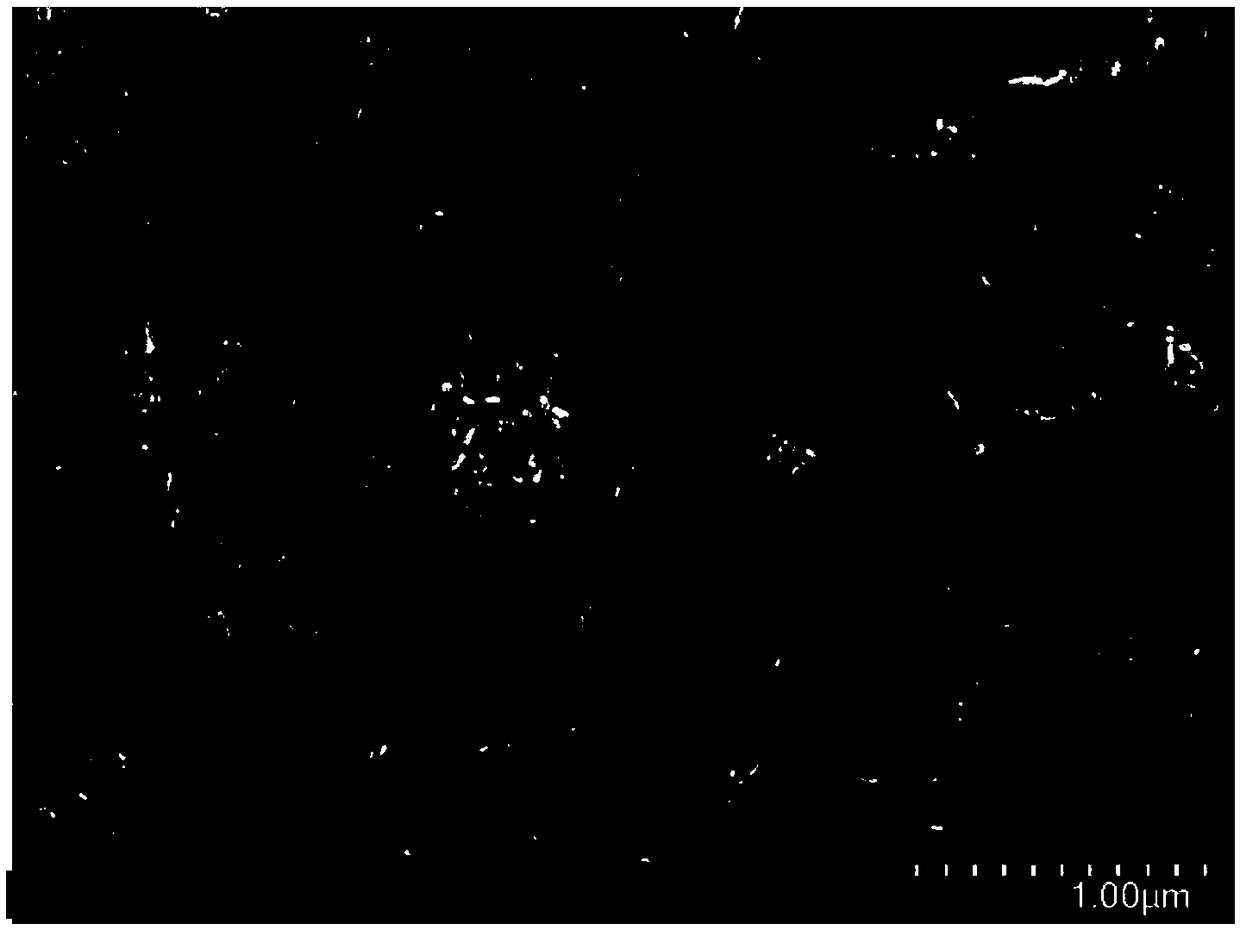

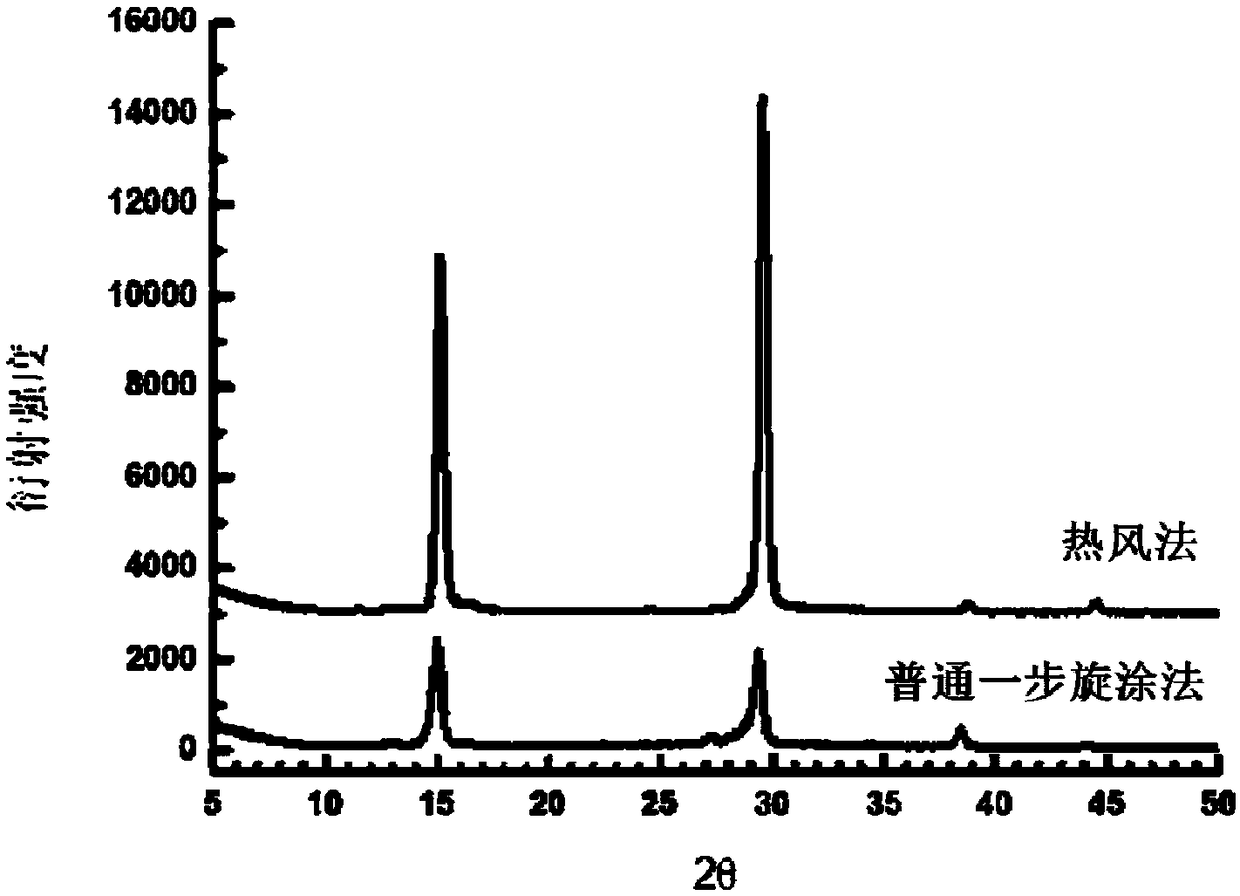

Image

Examples

Embodiment 1

[0043] a. Combine PEAI, MAI, PbI 2 Dissolve in DMF solvent according to the molar ratio of 2:2:3, and prepare the molecular formula as (PEA) 2 MA 2 Pb 3 I 10 Precursor solution, stirred at room temperature until the solution is clear, and filtered with a 0.22 μm filter membrane for future use, based on Pb 2+ The calculated concentration of the precursor solution was 0.3 mol / L.

[0044] b. Use a plasma cleaning machine to process the conductive substrate for 10 minutes, and finally obtain a conductive glass with good surface wettability.

[0045] c. In the present invention, when the precursor solution is dripped onto the substrate, a certain temperature still needs to be maintained. Therefore, the conductive substrate is placed on a heating plate for preheating before spin coating. The heating temperature is 180°C and the preheating time is 10 minutes.

[0046] d. Drop the precursor solution prepared in step a onto the hot conductive substrate, spin coating to spread the li...

Embodiment 2

[0051] a. Combine PEAI, MAI, PbI 2 Dissolve in DMF solvent according to the molar ratio of 2:2:3, and prepare the molecular formula as (PEA) 2 MA 2 Pb 3 I 10 Precursor solution, stirred at room temperature until the solution is clear, and filtered with a 0.22 μm filter membrane for future use, based on Pb 2+ The calculated concentration of the precursor solution was 0.6 mol / L.

[0052] b. Use a plasma cleaning machine to treat the conductive substrate for 15 minutes, and finally obtain a conductive glass with good surface wettability.

[0053] c. In the present invention, when the precursor solution is dropped onto the substrate, a certain temperature still needs to be maintained. Therefore, the conductive substrate is placed on a heating plate for preheating before spin coating. The heating temperature is 140°C and the preheating time is 10 minutes.

[0054] d. Drop the precursor solution prepared in step a onto the hot conductive substrate, spin coating to spread the li...

Embodiment 3

[0059] a. Combine PEAI, PbI 2 Dissolve in DMF solvent according to the molar ratio of 2:1, and prepare the molecular formula as (PEA) 2 PB 4 Precursor solution, stirred at room temperature until the solution is clear, and filtered with a 0.22 μm filter membrane for future use, based on Pb 2+ The calculated concentration of the precursor solution was 0.1 mol / L.

[0060] b. Use a plasma cleaning machine to process the conductive substrate for 30 minutes, and finally obtain a conductive glass with good surface wettability.

[0061] c. In the present invention, when the precursor solution is dropped onto the substrate, a certain temperature still needs to be maintained. Therefore, the conductive substrate is placed on a heating plate for preheating before spin coating. The heating temperature is 160°C and the preheating time is 10 minutes.

[0062] d. Drop the precursor solution prepared in step a onto the hot conductive substrate, spin coating to spread the liquid evenly to ob...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap