Horn vibrating piece sewn into wires and manufacturing method thereof

A manufacturing method and technology of vibrating sheet, which are applied in the direction of diaphragm structure, diaphragm extension, transducer diaphragm, etc., can solve the problems of loose deformation, affecting the sound quality output of the speaker, and the inability of the wire to be stabilized, so as to prevent the unbalanced situation, The effect of preventing deformation from loosening or breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

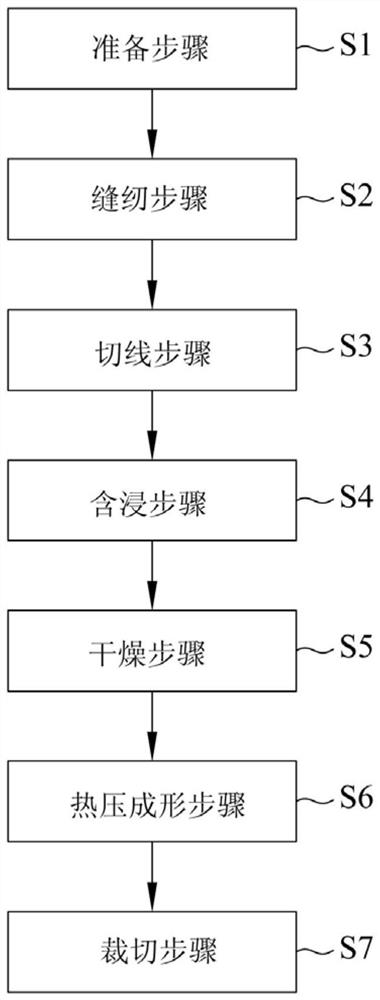

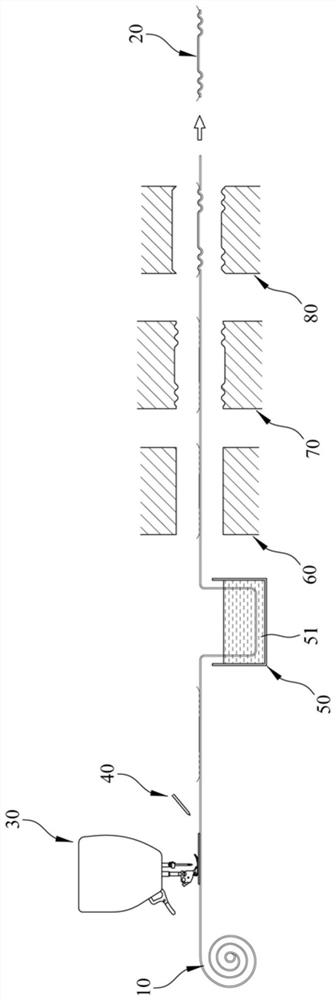

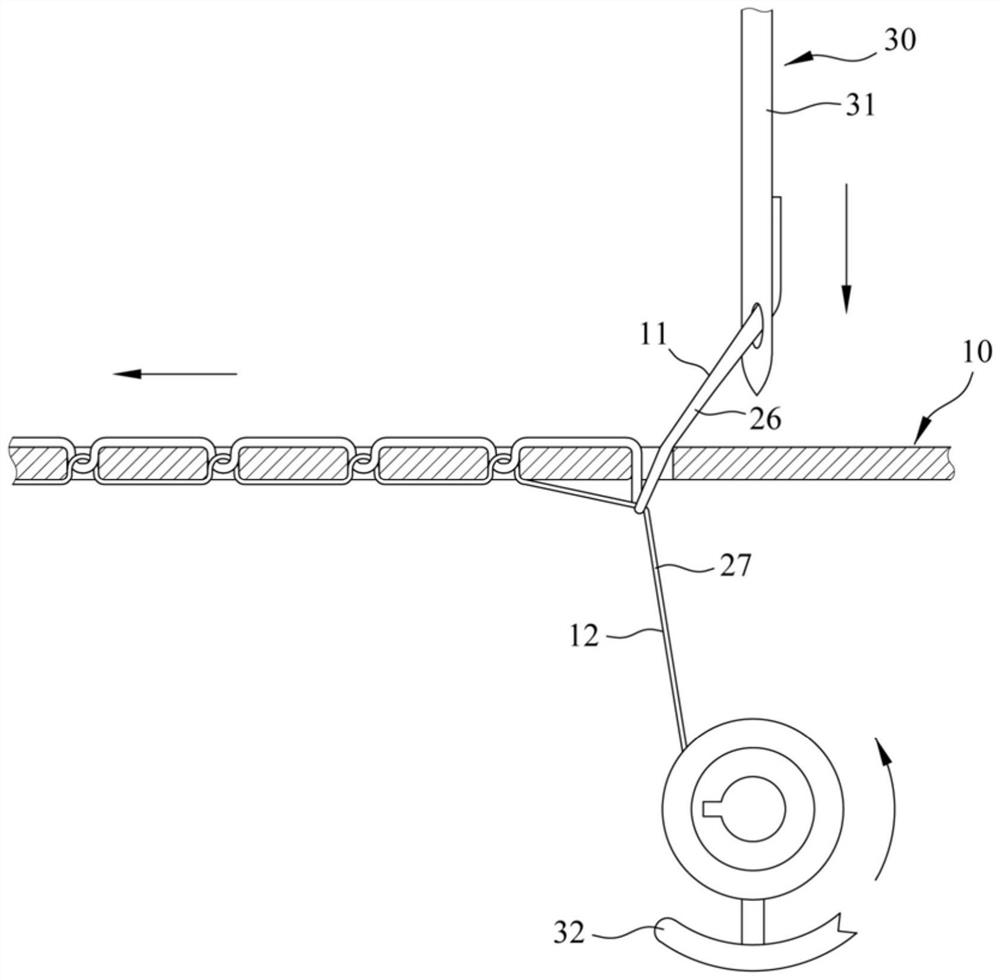

[0066] refer to figure 1 and figure 2 , and with Figure 3 to Figure 9 Shown are the flow chart of the manufacturing method, the schematic diagram of the manufacturing process, the schematic diagram of the tailoring action, the schematic diagram of the cutting action, the schematic diagram of the cloth material 10 after the thermoforming step S6, and the perspective view of the vibrating plate after the cutting step S7 according to the first embodiment of the present invention. Disclosed is a method for manufacturing a speaker vibrating piece sewn into wires, the method comprising:

[0067] A preparatory step S1, which places a cloth material 10 on a sewing platform (not shown in the figure) of a sewing device 30 having at least one bur 31 and a lower hook 32 .

[0068] A sewing step S2, during the continuous reciprocating lifting sewing stroke, cooperate with the reference Figure 3 to Figure 6 As shown, the sewing device 30 makes the bur 31 and the lower hook 32 continuo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com