Cotton picker frame structure

A frame structure and locomotive technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems that the maintenance space of the combined series pump is too small, and the balance of the frame is not solved, so as to ensure balance and stability , Improve balance and stability, and work stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

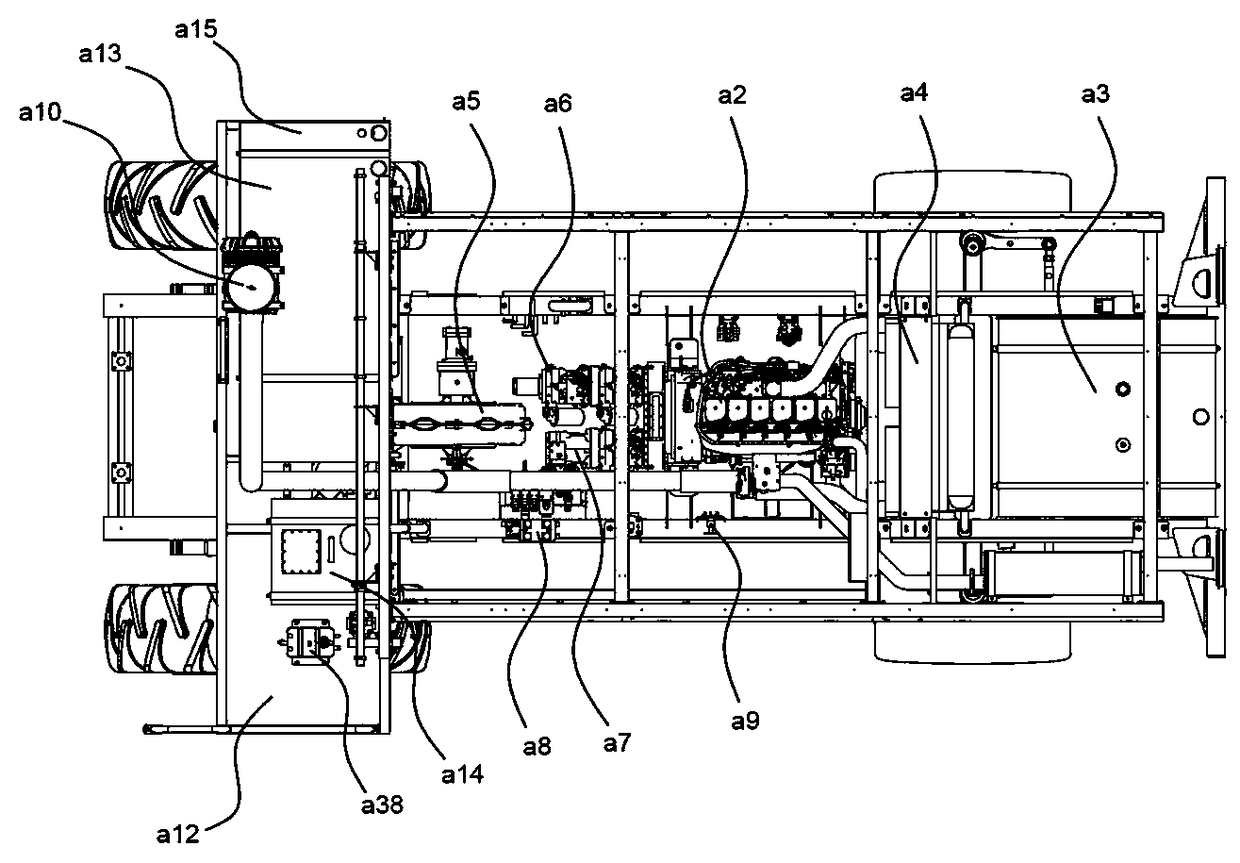

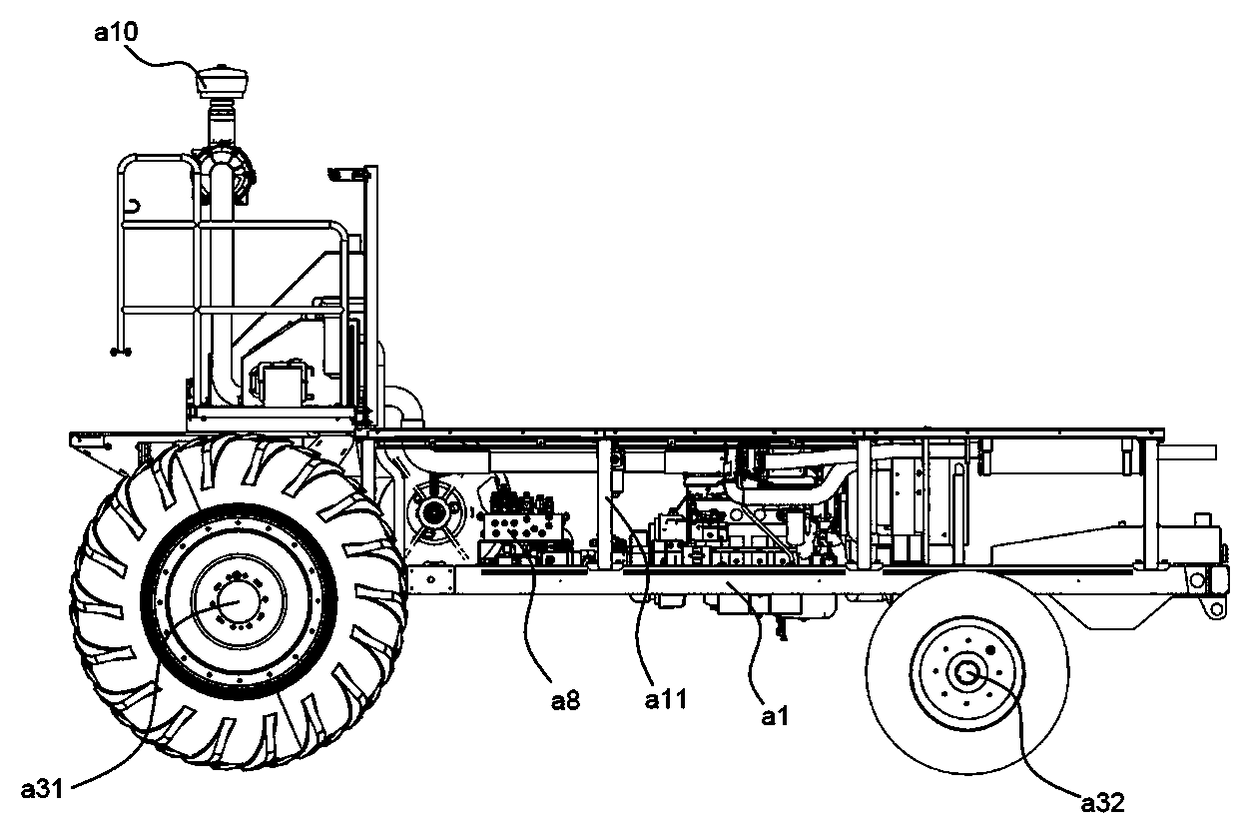

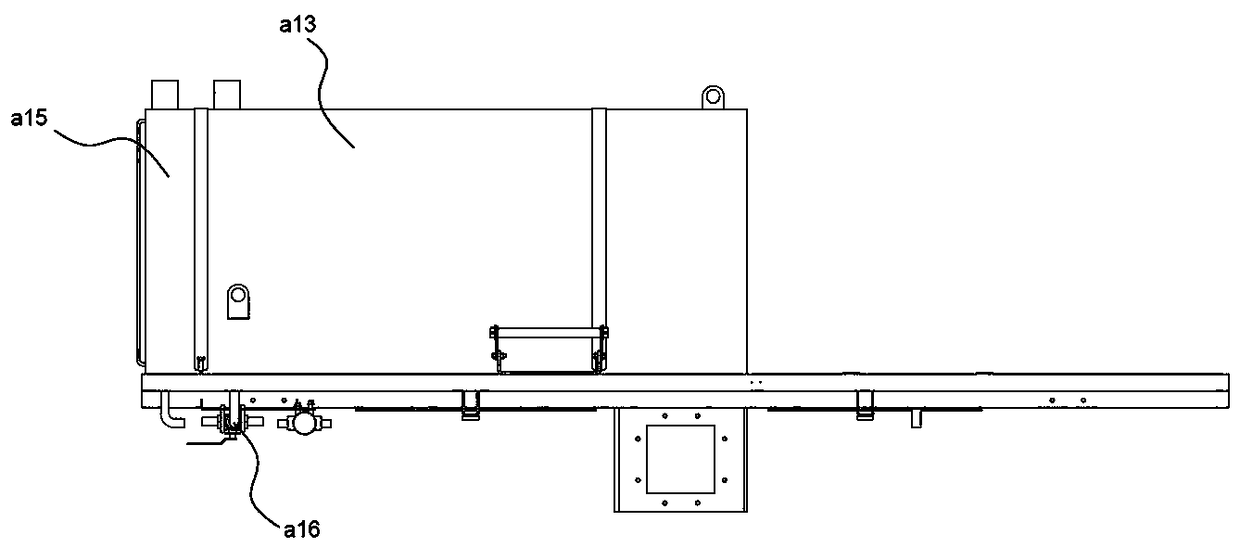

[0037] A frame structure of a cotton picker, comprising a frame main body, the power mechanism and other related parts of the whole vehicle are arranged on the frame main body a1, and a front axle mechanism and a rear axle mechanism are arranged under the frame main body a1. The bridge mechanism is used to drive the vehicle to walk, while the rear axle mechanism is used to control the steering of the vehicle.

[0038] Specifically, the above power mechanism mainly includes engine a2, transfer case, fuel tank a3, cooling water tank a4, fan a5, mining head and fan series pump a6, travel and system series pump a7, multi-way solenoid valve a8, battery, engine start motor etc. Wherein, a main power switch a9 is arranged between the storage battery and the engine starter motor, which is used to turn on and cut off the main power supply of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com