High-efficiency beef cattle slaughtering line

A technology for slaughtering lines and beef cattle, which is applied in slaughtering, slaughtering equipment, slaughtering plant equipment, etc., can solve the problems of reducing production line operation efficiency, difficulty in further decomposition, and reducing the quality of cattle blood, etc., to improve the level of civilized production, simple structure, and convenient bleeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

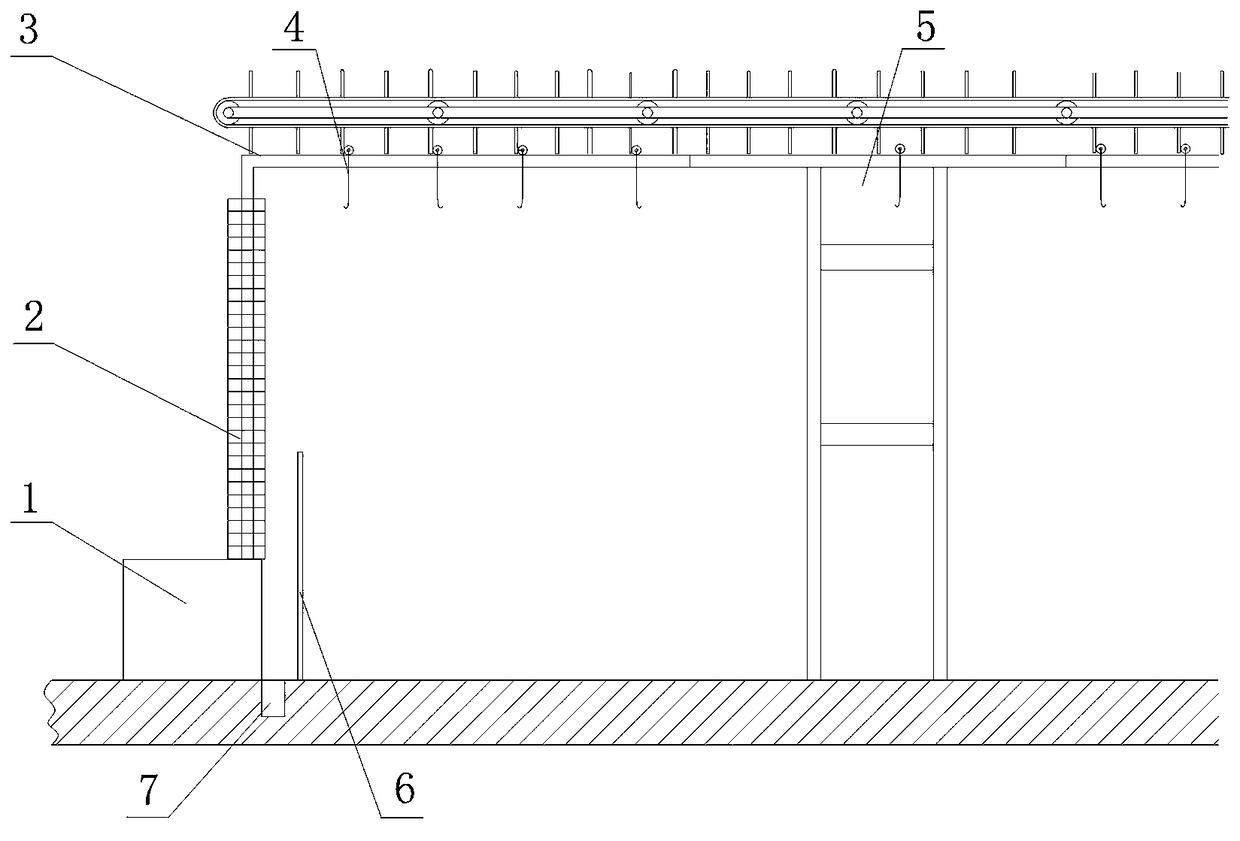

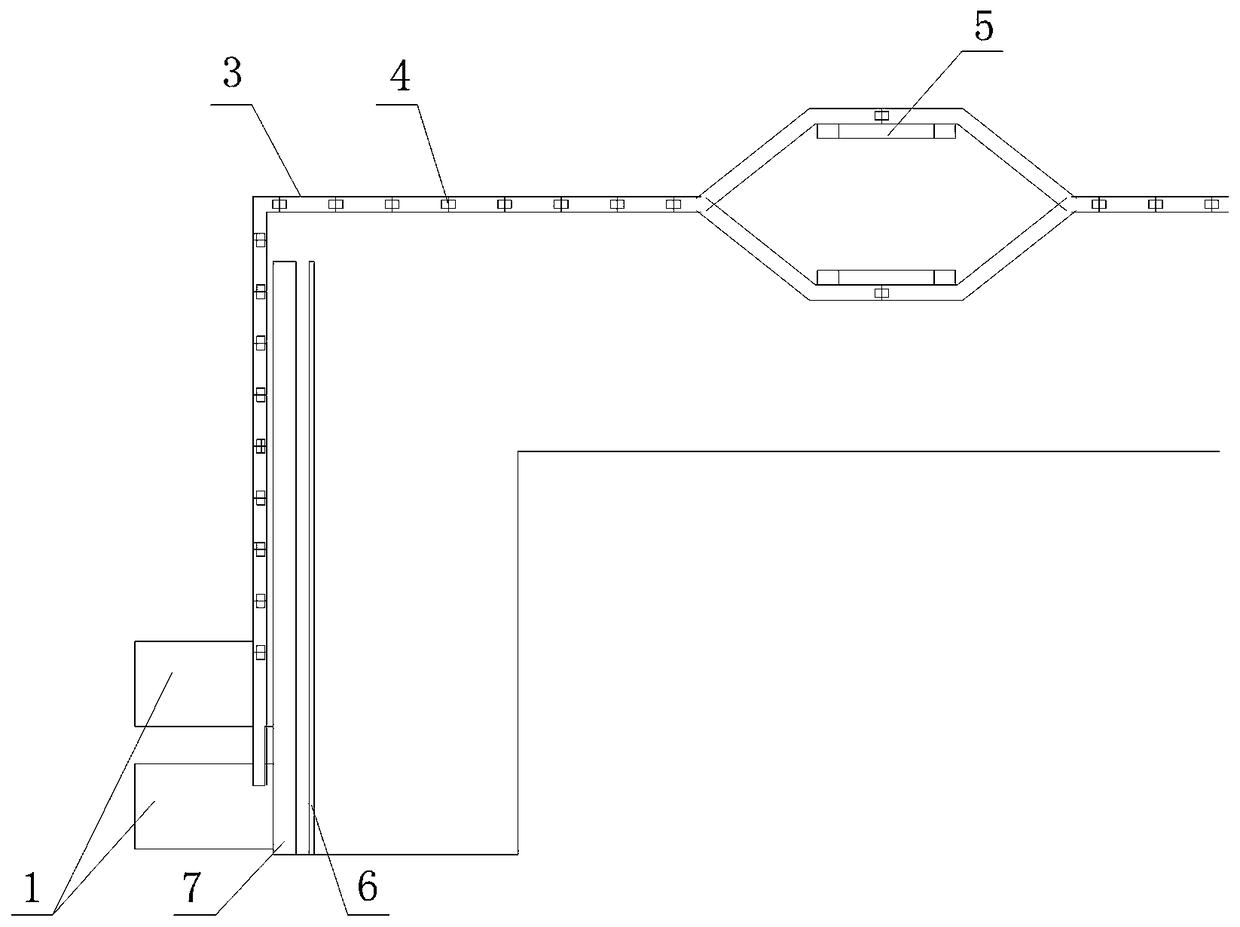

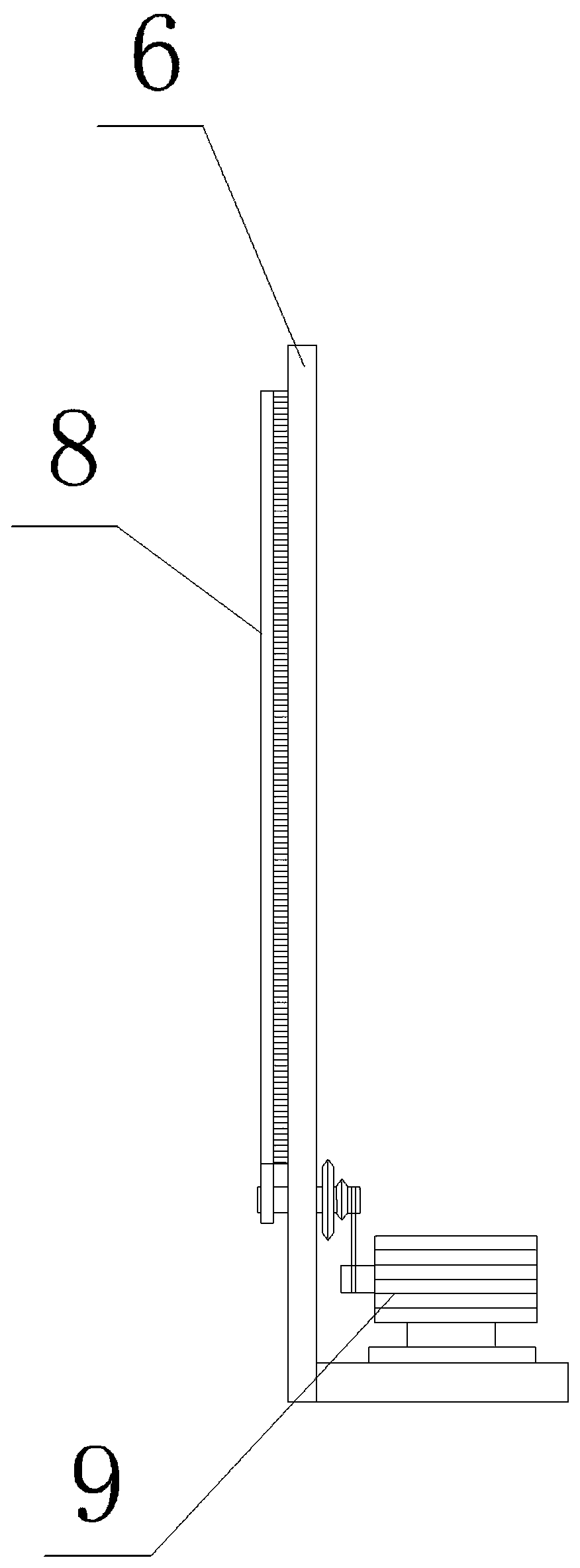

[0025] The first embodiment: figure 1 , figure 2 A high-efficiency beef cattle slaughtering line is given as an example, which includes a turning slaughter box 1 and a track 3. A hook 4 with rollers is arranged on the track, and a driving chain and a shifting tooth are arranged above the track to push the hook forward. During the slaughter operation, the beef cattle are driven into the overturning slaughter box 1 from the special channel after being cleaned and disinfected, and the box door is closed so that the head and neck are stretched out of the box. In order to minimize the pain of the cattle, the box is turned over while being instantly stunned by electric shock, then slaughtered and bled according to religious requirements, and then hung with hook 4 and lifted to the elevated track by lifter 2, the first section of track 1 The main thing is to continue bloodletting, also known as bleeding. On the ground of this section from slaughtering to bleeding, a blood receivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com