Shaping device for hat production

A technology for hats and equipment, which is applied in the field of shaping equipment for hat production, can solve the problems of low production efficiency and low energy utilization rate, and achieve the effects of simple structure, easy manufacturing and promotion, and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

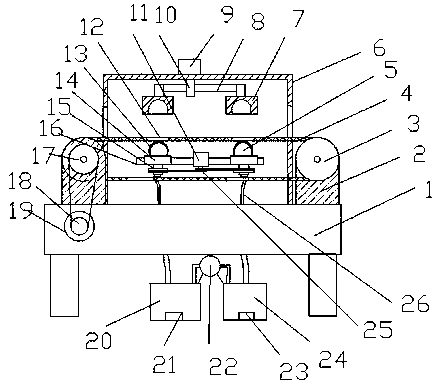

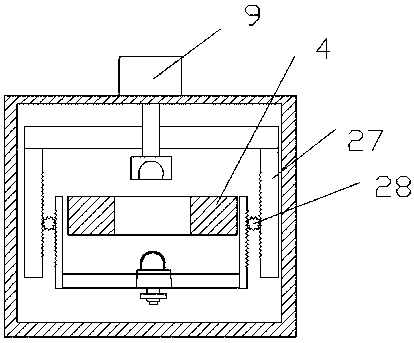

[0023] see Figure 1-3 , a sizing device for hat production, including a workbench 1, a housing 6 and a lifting platform 16. The four corners of the lower surface of the workbench 1 are fixed with vertical support columns, and the support columns have a supporting and fixing effect on the workbench 1. The left and right ends of the upper surface of the workbench 1 are fixed with vertical columns 2, and the top of the column 2 The transmission roller 3 is connected in rotation, and the transmission roller 3 can rotate freely on the column 2. The conveying roller 3 is provided with a conveying belt 4 , and the conveying belt 4 rotates with the conveying roller 3 . A number of positioning holes 12 are evenly opened on the conveyor belt 4 . The near end of described workbench 1 is fixedly installed with second motor 19, and the output shaft of second motor 19 is vertically connected with second driving disc 18, under the drive of second motor 19, second driving disc 18 and the s...

Embodiment 2

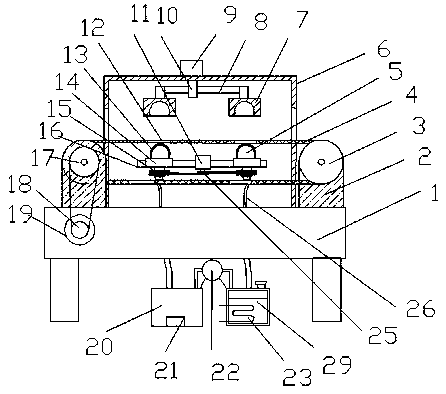

[0030] see image 3 , On the basis of embodiment 1, the second air tank 24 is replaced with a water tank 29, the top of the water tank 29 is provided with a water inlet, and a valve is provided on the water inlet, and clear water can be added in the water tank 29 by opening the valve. A heater 23 is arranged in the water tank 29, and the heater 23 can heat the clear water and generate steam, and the steam enters the hot lower mold 5 to iron the hat, and the setting effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com