Inner pot suitable for electromagnetic heating, manufacturing method of inner pot, and cooking utensil

A technology for cooking utensils and inner pots, which is applied in the direction of utensils with integral electric heating devices, the structure of cooking utensils, and special materials for cooking utensils, etc., which can solve the problem of poor bonding between the magnetic layer and the pot body, and the position limit of the magnetic layer formation Unclear and other problems, to achieve the effect of beautiful appearance, clear boundaries, and strong binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

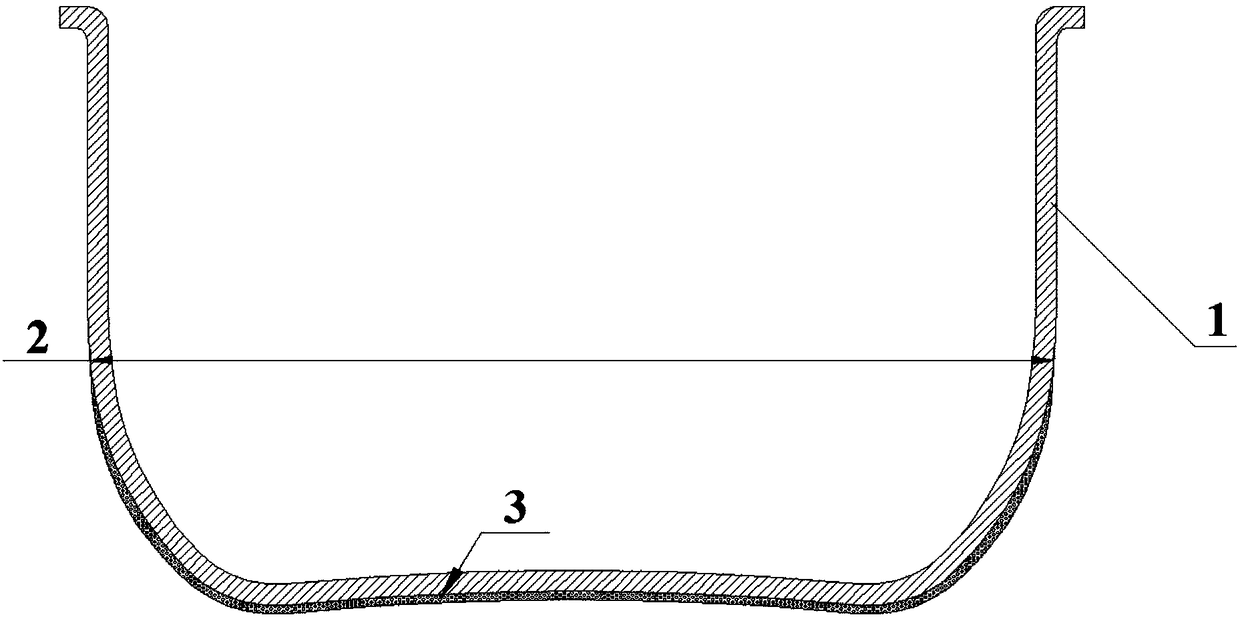

[0034] According to a preferred embodiment of the present invention, the pot body 1 at least includes a straight portion with a maximum outer diameter and a downwardly reduced diameter portion located below the straight portion and connected to the straight portion. In this preferred embodiment, the magnetic permeable layer 3 is formed on the outer wall of the pot below the straight part. Further preferably, the magnetically permeable layer 3 makes a smooth transition between the straight portion and the downwardly reduced diameter portion, thereby displaying an aesthetically pleasing appearance. Still further preferably, on the outer wall of the pot of the downwardly reduced diameter portion connected to the straight cylinder portion, the thickness of the magnetic permeable layer 3 gradually decreases from bottom to top.

[0035] For the inner pot of the above-mentioned preferred embodiment, in the pot body 1, an upwardly reduced diameter part can be arranged on the upper par...

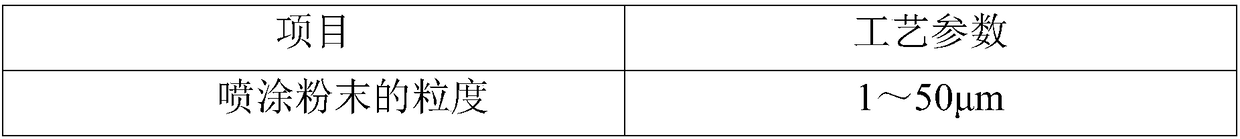

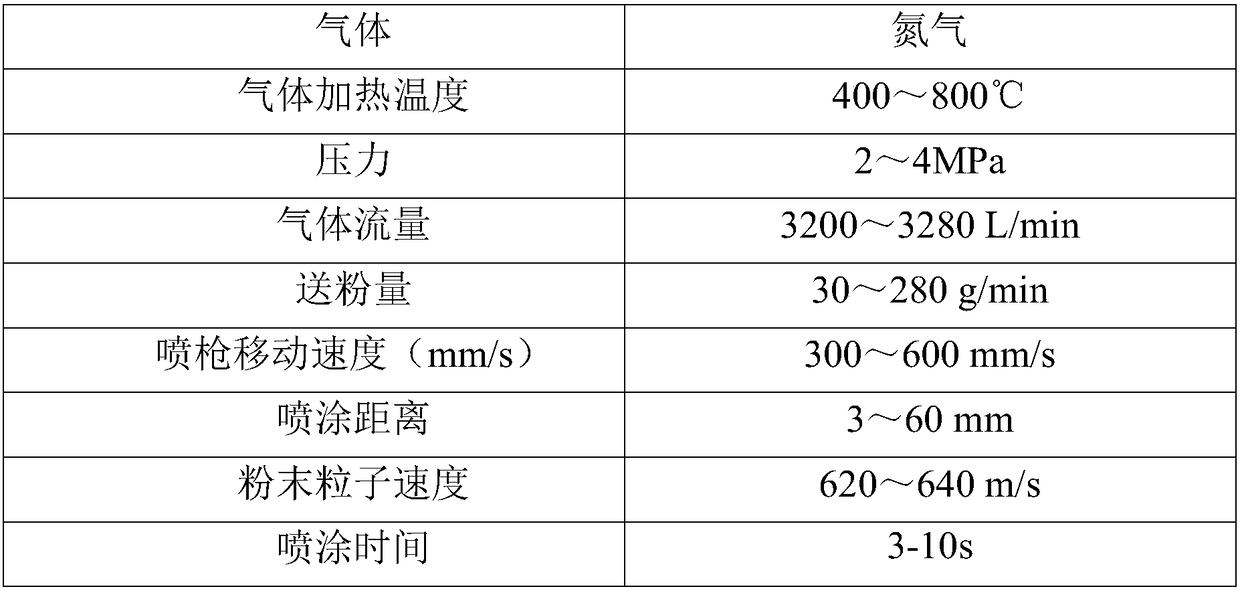

Embodiment 1

[0057] The 3003 aluminum plate is stretched and stamped to obtain a pot body with a straight part at the top and a bottom part at the bottom. The diameter of the straight part is 220 mm, and the diameter of the bottom of the pot is 180 mm. The height of the straight part and the bottom part is The ratio is 3:1, the outer diameter of the bottom part of the pot gradually decreases from top to bottom, the side wall of the bottom part of the pot is arc-shaped, and the included angle between the tangent line of the arc and the vertical direction is 0-45°. Afterwards, the outer surface of the pot body is degreased and degreased. Then the pot body is fixed on the rotation tooling, the manipulator is set, the spraying range is from the center of the bottom of the inner pot to the maximum radius of the side wall of the pot body, and the cold spraying is carried out under the conditions of the parameters shown in Table 2 below while the inner pot is rotating. Thus, the inner pot A1 is m...

Embodiment 2

[0059] The 3003 aluminum plate is stretched and stamped to obtain a pot body with a straight part at the top and a bottom part at the bottom. The diameter of the straight part is 217 mm, and the diameter of the bottom of the pot is 160 mm. The height of the straight part and the bottom part is The ratio is 3.5:1, the outer diameter of the bottom part of the pot gradually decreases from top to bottom, the side wall of the bottom part of the pot is arc-shaped, and the included angle between the tangent line of the arc and the vertical direction is 0-45°. Afterwards, the outer surface of the pot body is degreased and degreased. Then the pot body is fixed on the rotation tooling, the manipulator is set, the spraying range is from the center of the bottom of the inner pot to the maximum radius of the side wall of the pot body, and the cold spraying is carried out under the conditions of the parameters shown in Table 2 below while the inner pot is rotating. Thus, the inner pot A2 wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com