Automatic sorting method of customized furniture plate element vertical placement transmission

A technology for panels and furniture, which is applied in the field of automatic sorting for the vertical placement and transmission of customized furniture panels, can solve the problems of high work intensity of sorting personnel, low efficiency of manual sorting lines, and high sorting error rate, and achieve good sorting. The effect of improving the sorting efficiency, improving the sorting efficiency and shortening the moving path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

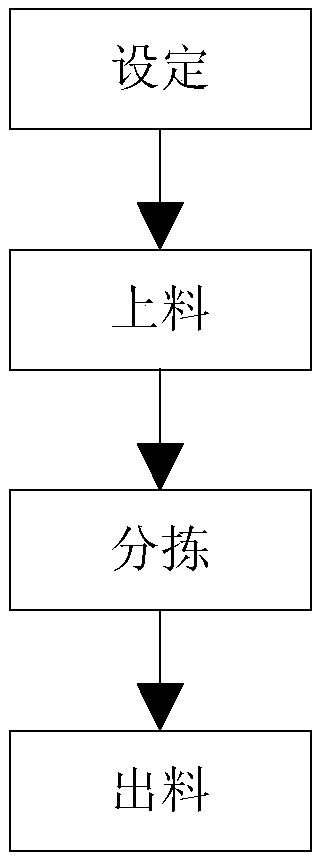

[0055] This embodiment provides an automatic sorting method for vertical transmission of customized furniture panels, the process of which is as follows figure 1 As shown, including the setting process, loading process, sorting process and discharging process executed in sequence;

[0056] Described setting process refers to, obtains the information of all boards of current batch to be sorted; Sets respectively the corresponding relationship between each board and the board vertical placement space of sorting device;

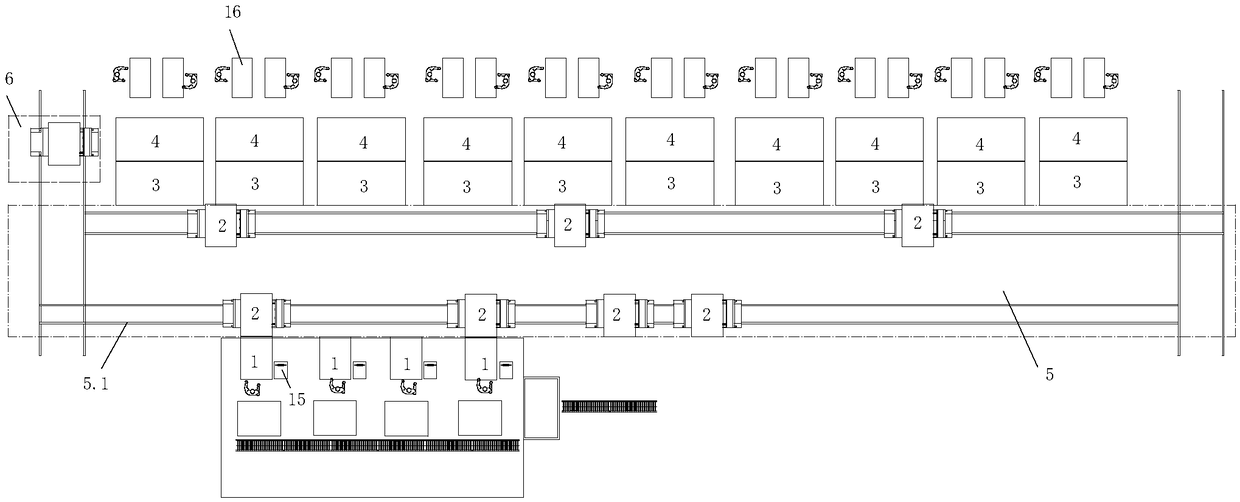

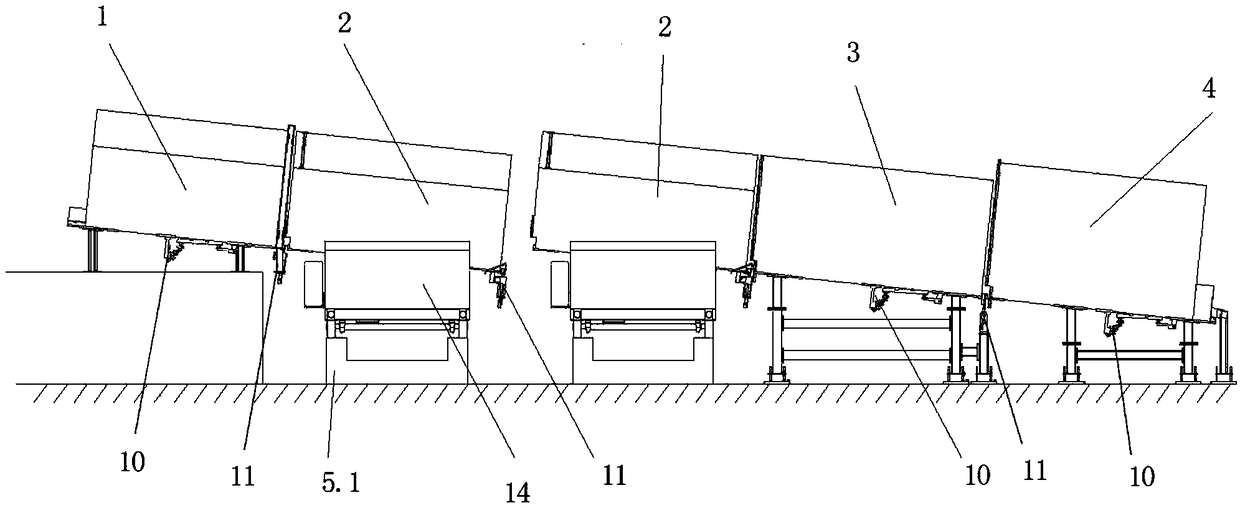

[0057] The feeding process refers to grouping the boards of the current batch to be sorted for information scanning, and feeding them upright and side by side into the board vertical storage space of the feeding device; The vertical storage space is transferred to the vertical storage space of the mobile device;

[0058] The sorting process refers to that the mobile device carries the boards and moves, so that the board vertical storage spaces of the mobile de...

Embodiment 2

[0109] This embodiment customizes the automatic sorting method for the vertical transportation of furniture panels. Perform intermittent braking on the rollers to slow down the sliding speed of the plate; the braking time refers to the braking time set according to the weight and size parameters. Different braking times are used for different panels. On the one hand, it can avoid the braking time being too short to effectively slow down the sliding speed of the panel, which will cause the panel to be damaged when it hits; on the other hand, it can avoid the panel sliding due to too long braking time. The speed is too slow, which leads to low transmission efficiency. Adjusting the braking time according to the weight and size parameters of the board can make the board have an appropriate sliding speed and improve the transmission efficiency.

[0110] The preferred solution is: the weight and dimension parameters of the panel include the quality of the panel and the size of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com