Mold insert ultrasonic cleaning process

An ultrasonic and insert technology, applied in the field of ultrasonic cleaning of mold inserts, can solve the problems of not considering the drying process, wasting manpower and material resources, affecting efficiency, etc., and achieve significant economic benefits, labor saving, and efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

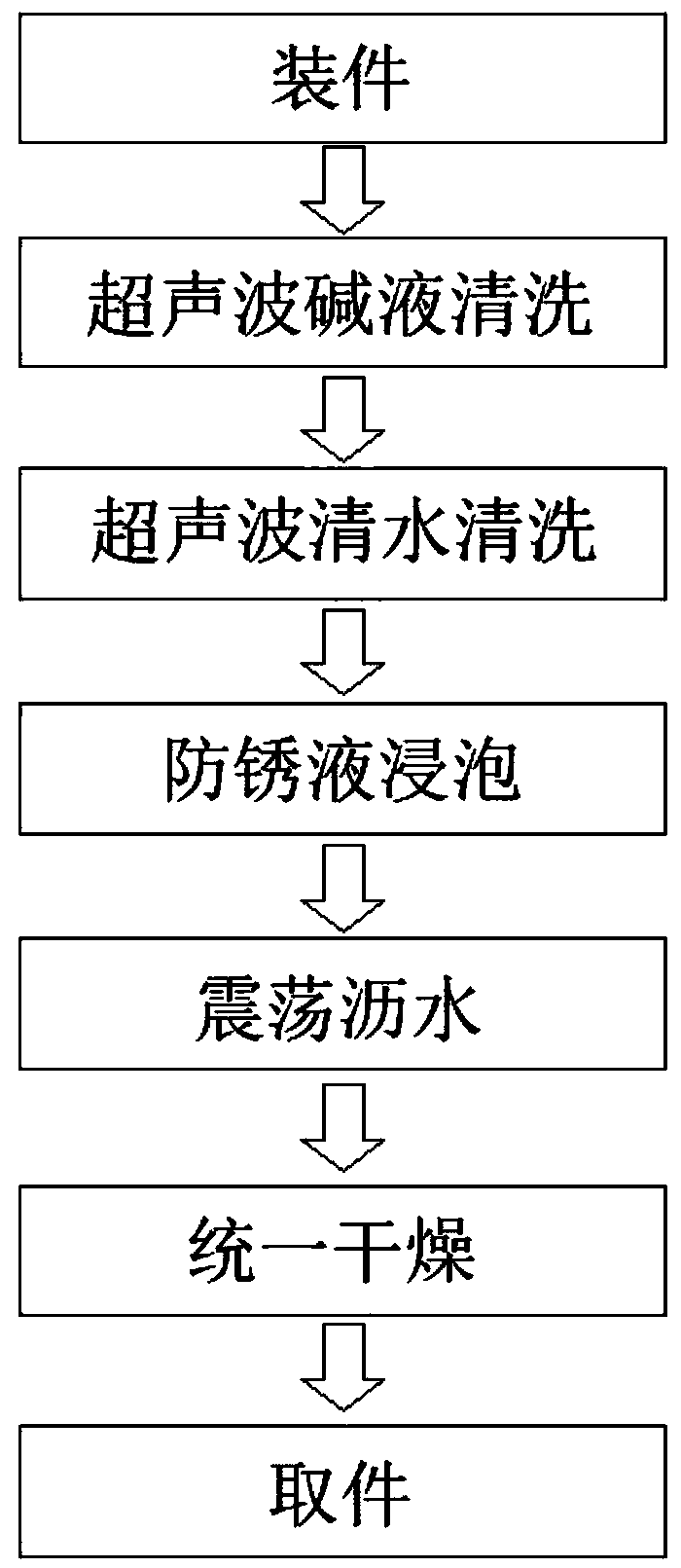

[0051] see figure 1 , an ultrasonic cleaning process for mold inserts, comprising the following steps:

[0052] Step 1. Installing parts: Put the inserts to be cleaned on the stainless steel mesh 702 of the cleaning basket;

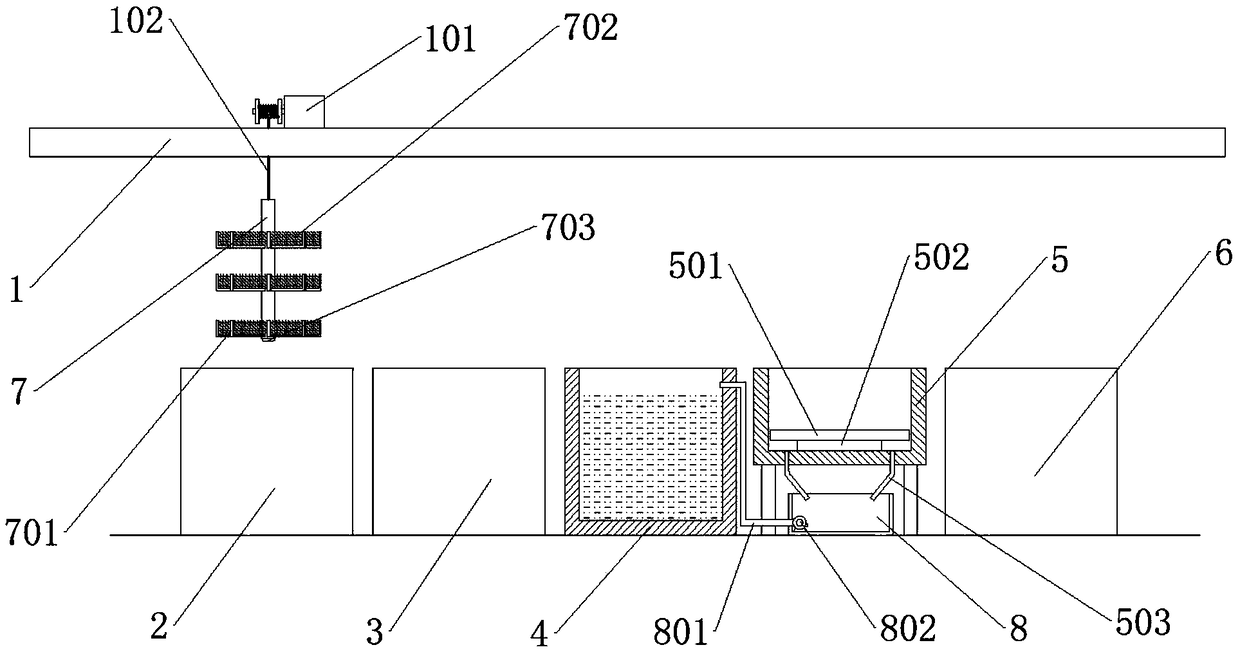

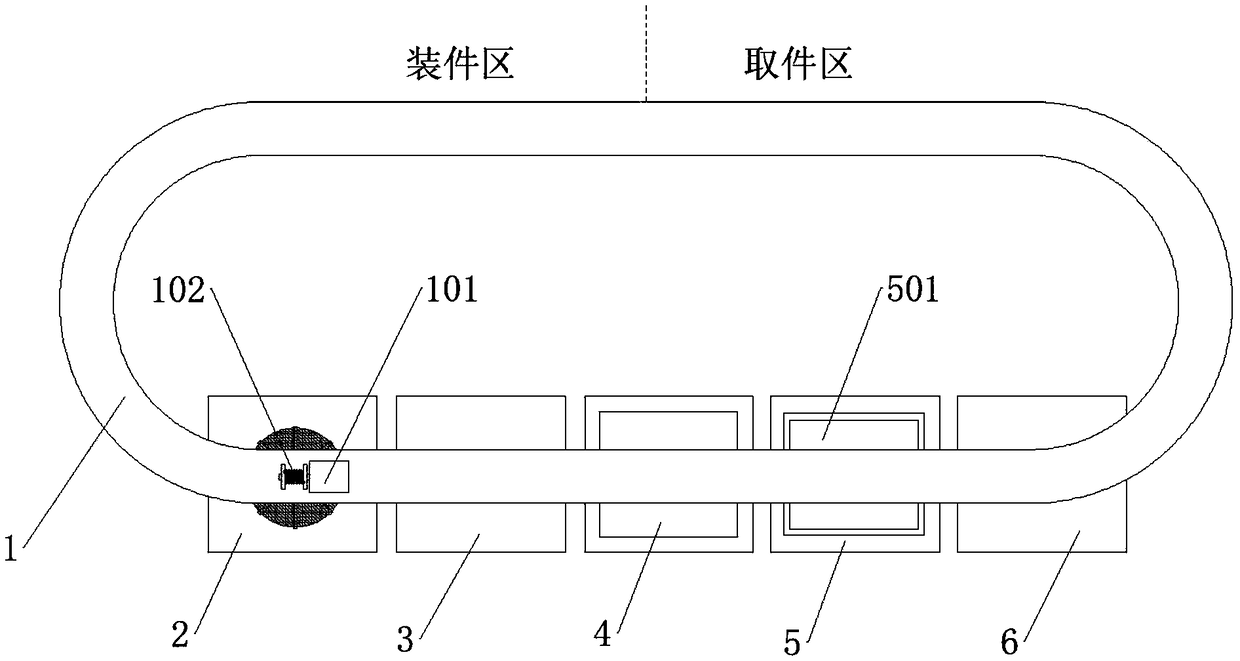

[0053] see Figure 4-6 , the cleaning basket includes a cleaning basket connecting rod 7, a plurality of cleaning basket brackets 701 are fixedly connected to the cleaning basket connecting rod 7, and stainless steel mesh 702 is fixedly connected to the plurality of cleaning basket brackets 701, and the stainless steel mesh 702 can not only be used as an insert It provides elasticity, and can also increase the contact area between the insert and the outside world, without affecting the ultrasonic cleaning, and the efficiency of soaking anti-rust liquid and drying process at the same time is higher. The lower end of the connecting rod 7 of the cleaning basket is fixedly connected with a protective block 703. Basket connecting rod 7 has protection and cer...

Embodiment 2

[0069] see figure 1 , an ultrasonic cleaning process for mold inserts, comprising the following steps:

[0070] Step 1. Installing parts: Put the inserts to be cleaned on the stainless steel mesh 702 of the cleaning basket;

[0071] see Figure 4-6 , the cleaning basket includes a cleaning basket connecting rod 7, a plurality of cleaning basket brackets 701 are fixedly connected to the cleaning basket connecting rod 7, and stainless steel mesh 702 is fixedly connected to the plurality of cleaning basket brackets 701, and the stainless steel mesh 702 can not only be used as an insert It provides elasticity, and can also increase the contact area between the insert and the outside world, without affecting the ultrasonic cleaning, and the efficiency of soaking anti-rust liquid and drying process at the same time is higher. The lower end of the connecting rod 7 of the cleaning basket is fixedly connected with a protective block 703. Basket connecting rod 7 has protection and cer...

Embodiment 3

[0081] see figure 1 , an ultrasonic cleaning process for mold inserts, comprising the following steps:

[0082] Step 1. Installing parts: Put the inserts to be cleaned on the stainless steel mesh 702 of the cleaning basket;

[0083] see Figure 4-6, the cleaning basket includes a cleaning basket connecting rod 7, a plurality of cleaning basket brackets 701 are fixedly connected to the cleaning basket connecting rod 7, and stainless steel mesh 702 is fixedly connected to the plurality of cleaning basket brackets 701, and the stainless steel mesh 702 can not only be used as an insert It provides elasticity, and can also increase the contact area between the insert and the outside world, without affecting the ultrasonic cleaning, and the efficiency of soaking anti-rust liquid and drying process at the same time is higher. The lower end of the connecting rod 7 of the cleaning basket is fixedly connected with a protective block 703. Basket connecting rod 7 has protection and cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com