Production method of SD420W corrugated steel bar

A production method and technology of bamboo steel bars, applied to bending workpieces, metal processing equipment, metal rolling, etc., can solve the problems of low pass rate of production methods, and achieve uniform and stable longitudinal rib size, high reliability, and product pass rate Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1, the used finishing mill of producing D25 title SD420W bamboo joint steel bar comprises K1 frame 1, K2 frame 2, K3 frame 3, K4 frame 4, K5 frame 5 and K6 frame 6, and the production process is as follows :

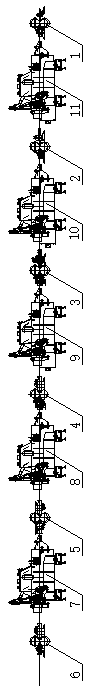

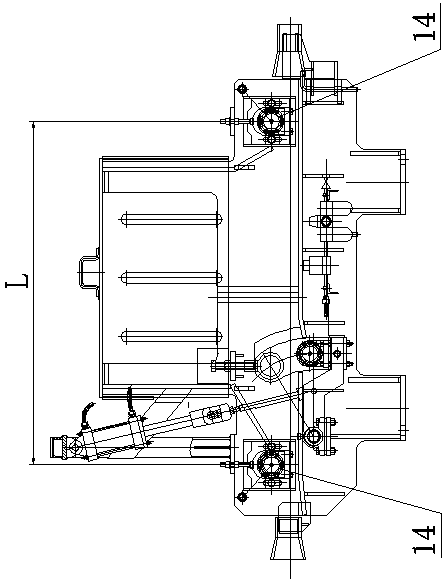

[0060] A. If figure 2 As shown, the first vertical looper 7 is set between the K6 frame 6 and the K5 frame 5 of the finishing mill, the second vertical looper 8 is set between the K5 frame 5 and the K4 frame 4, and the K4 machine The third vertical looper 9 is set between frame 4 and K3 frame 3, the fourth vertical looper 10 is set between K3 frame 3 and K2 frame 2, between K2 frame 2 and K1 frame 1 Between install the fifth vertical looper 11, such as image 3 As shown, the distance L between the two shaping rollers 14 of the fifth vertical looper 11 is 1700mm;

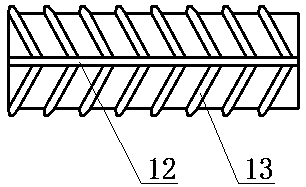

[0061] B. If Figure 4 , Figure 6 As shown, the passes of K6 stand 6 and K4 stand 4 of the finishing mill are all set to ellipse; as Figure 5 , Figure 7 , Figure 9 As shown, the h...

Embodiment 2

[0066] Embodiment 2, the finishing mill used in the production of D22 title SD420W bamboo steel bar includes K1 frame 1, K2 frame 2, K3 frame 3, K4 frame 4, K5 frame 5 and K6 frame 6, the production process is as follows :

[0067] A. If figure 2 As shown, the first vertical looper 7 is set between the K6 frame 6 and the K5 frame 5 of the finishing mill, the second vertical looper 8 is set between the K5 frame 5 and the K4 frame 4, and the K4 machine The third vertical looper 9 is set between frame 4 and K3 frame 3, the fourth vertical looper 10 is set between K3 frame 3 and K2 frame 2, between K2 frame 2 and K1 frame 1 Between install the fifth vertical looper 11, such as image 3 As shown, the distance L between the two shaping rollers 14 of the fifth vertical looper 11 is 1700mm;

[0068] B. If Figure 4 , Figure 6 As shown, the passes of K6 stand 6 and K4 stand 4 of the finishing mill are all set to ellipse; as Figure 5 , Figure 7 , Figure 9 As shown, the hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com