Cutting machine capable of electrified work

A technology for live operation and cutting machine, which is applied to shearing devices, hand-held metal shearing equipment, overhead line/cable equipment, etc. Accidents, the effect of ensuring efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

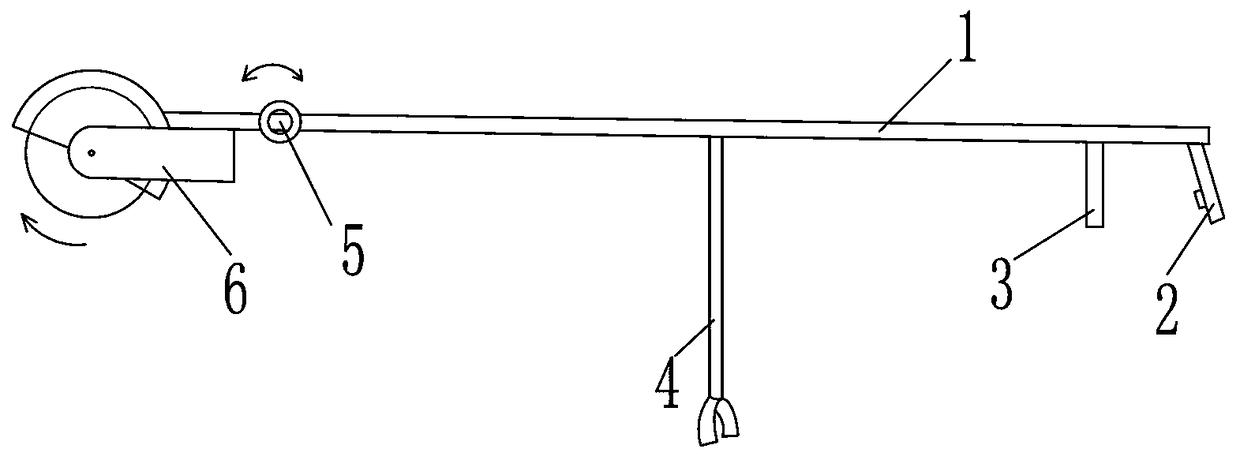

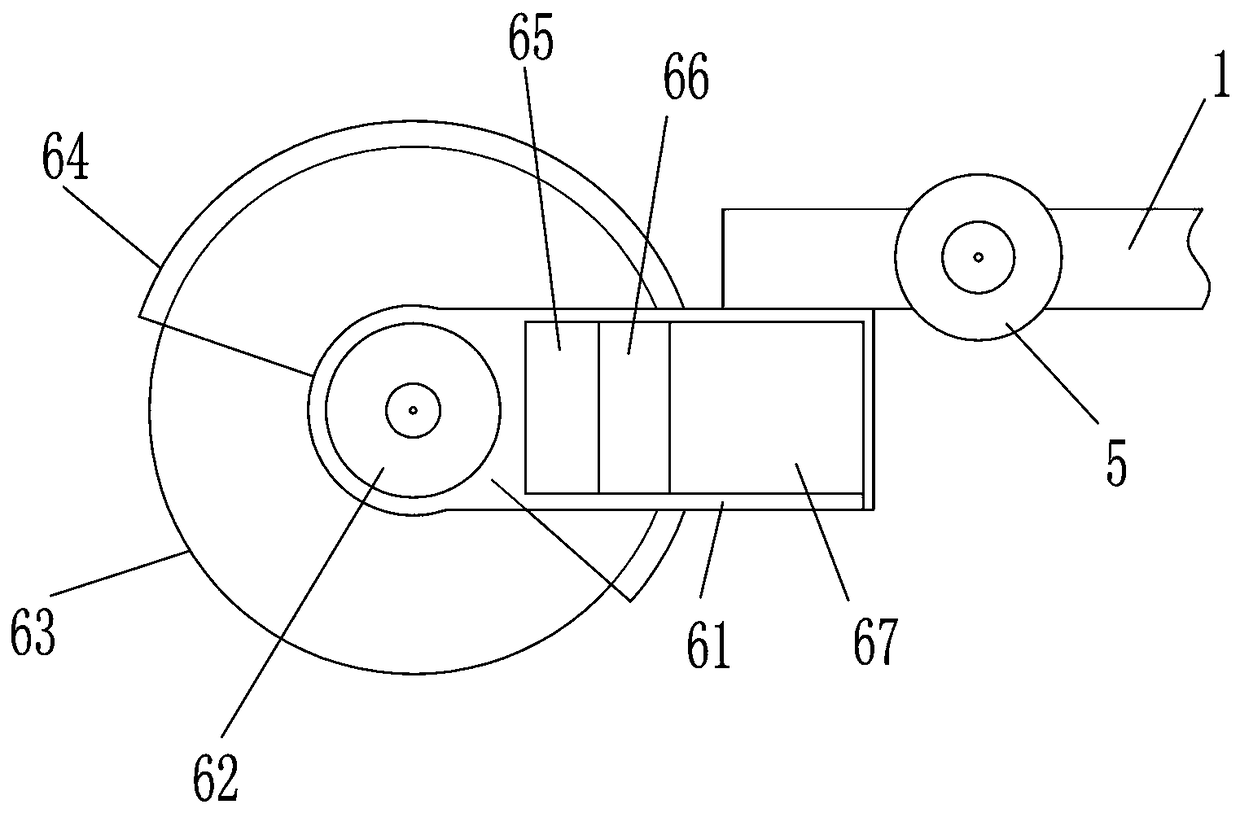

[0018] Numbers in the figure, number 1 stands for insulating rod, number 2 stands for switch handle, number 3 stands for stable handle, number 4 stands for fork support rod, number 5 stands for angler, number 6 stands for cutting mechanism, and number 61 stands for insulating casing , the symbol 62 represents the driving motor, the symbol 63 represents the cutting disk, the symbol 64 represents the insulating shield of the cutting disk, the symbol 65 represents the motor controller, the symbol 66 represents the communication circuit module, and the symbol 67 represents the power supply.

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and technical solutions, and the implementation of the present invention will be described in detail through preferred embodiments, but the implementation of the present invention is not limited thereto.

[0020] Aiming at the problems that many operations are not changed in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com