Micro SD card special-shaped frame cutting process

A cutting process and special-shaped technology, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of large fluctuations in product yield, product pollution of the environment, and low grinding precision, so as to reduce the packaging process, reduce costs, The effect of improving product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] A kind of Micro SD card special-shaped frame cutting process, it comprises the following steps:

[0051] S100, place the entire material on the cutting platform, the cutting platform is a vacuum adsorption platform, and the vacuum value is less than -60kPa, which can ensure that the material cannot move during the cutting process, thereby improving the processing accuracy of the product.

[0052] S200, use a vision system to locate the entire strip of material. In this embodiment, the vision system is a BIV system.

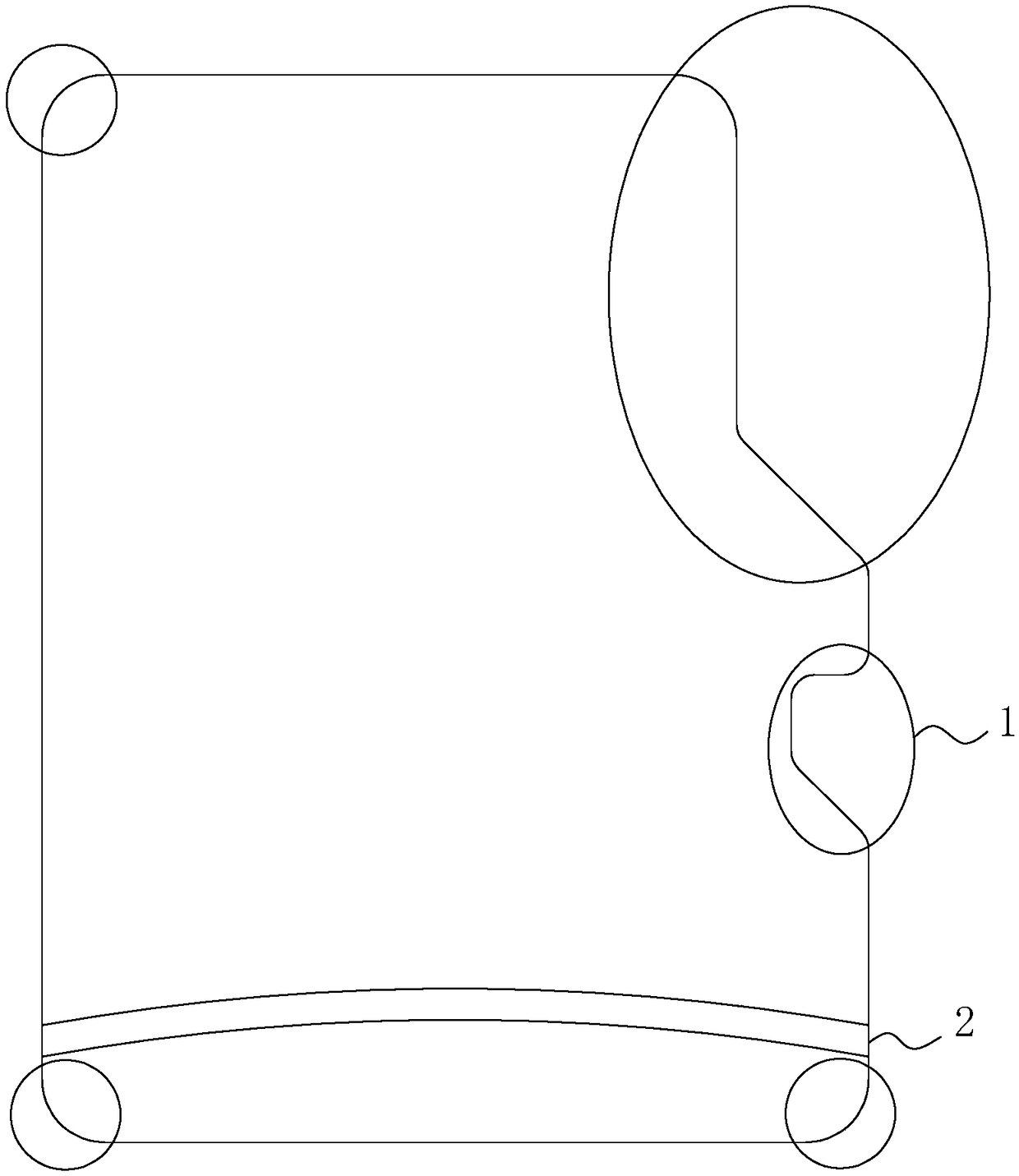

[0053] S300, see figure 1 , use laser to cut the special-shaped parts 1 of all products on the whole material. In this embodiment, a single product includes five special-shaped parts 1. Compared with the traditional cutting technology, it is not necessary to cut the whole material beforehand. Into a single chip, can greatly improve UPH, reduce the packaging process, and reduce costs;

[0054] The laser power is 50~54W, below this value the material cannot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com