Micro-damaged tube fetching device and process for heat transfer tube of shell-tube heat exchanger

A shell-and-tube heat exchanger and heat transfer tube technology, applied in the field of mechanical processing, can solve the problems of economic loss, heat exchanger damage, heat exchanger can not continue to operate and use, and achieve the effect of saving economic resources and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the drawings and embodiments.

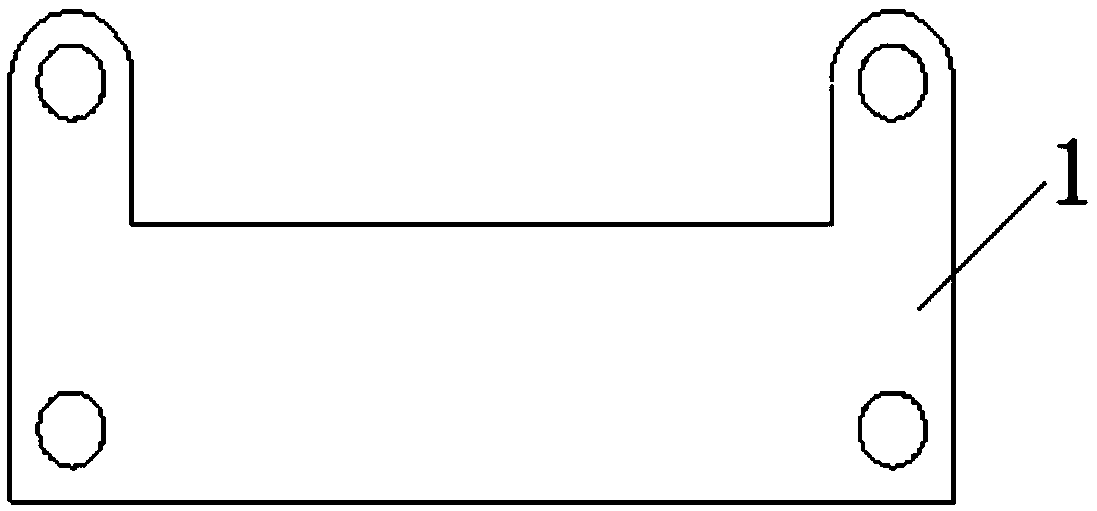

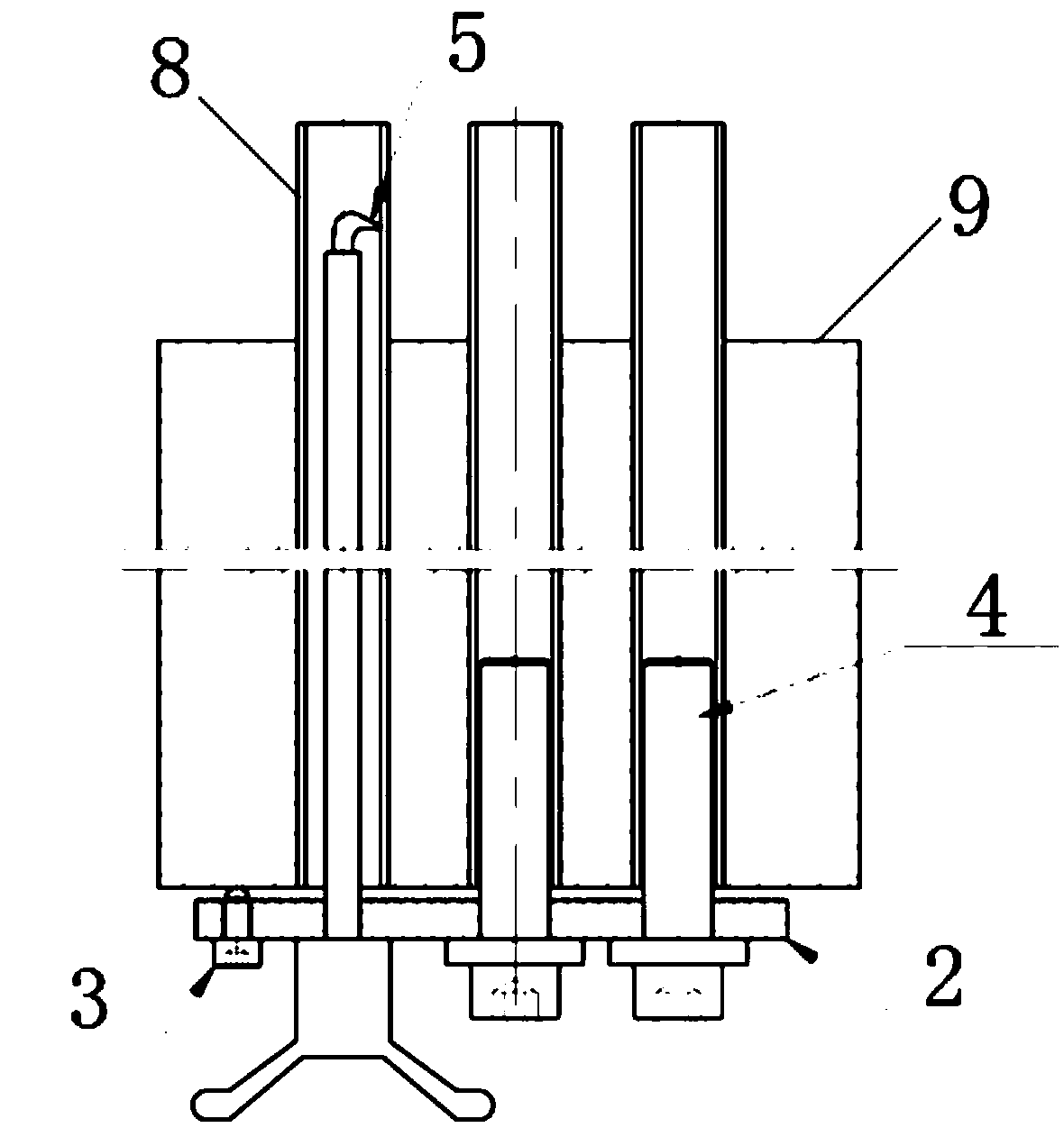

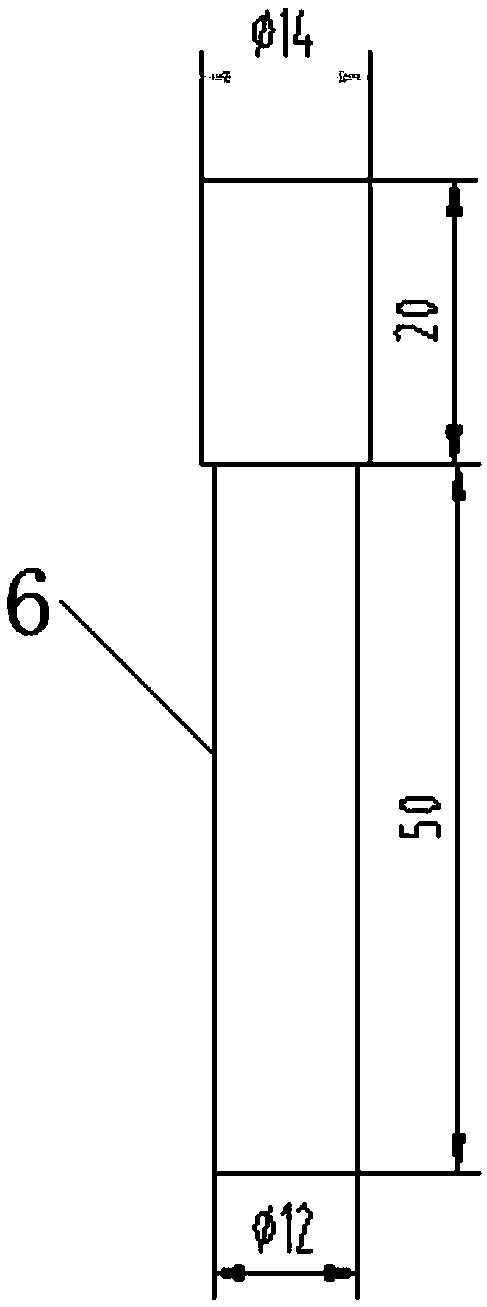

[0028] Such as Figure 1 to Figure 4 As shown, a shell-and-tube heat exchanger heat transfer tube micro-damage tube removal device includes a magnetic drill fixing tool 1, a heat transfer tube inner cutter, a heat transfer tube ejection tool 6 and a tube top rod 7. Magnetic drill fixing tool 1 is used to fix the magnetic drill. The heat transfer tube internal cutting device is used to cut the heat transfer tube 8 from the inside. The heat transfer tube ejection tool 6 is used to insert the heat transfer tube 7 and push it upward. The tube ejector rod 7 is used to push up the heat transfer tube ejection tool 6 so as to realize the separation of the heat transfer tube 8 and the tube sheet 9.

[0029] The magnetic drill fixing tool 1 has a U-shaped plate shape as a whole, and a positioning hole is provided on the upper end surface for fixing the magnetic drill. The magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com