Workpiece machining method and machining system

A processing method and workpiece technology, applied in the field of workpiece processing methods and processing systems, can solve the problems of low production yield and achieve the effect of improving production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

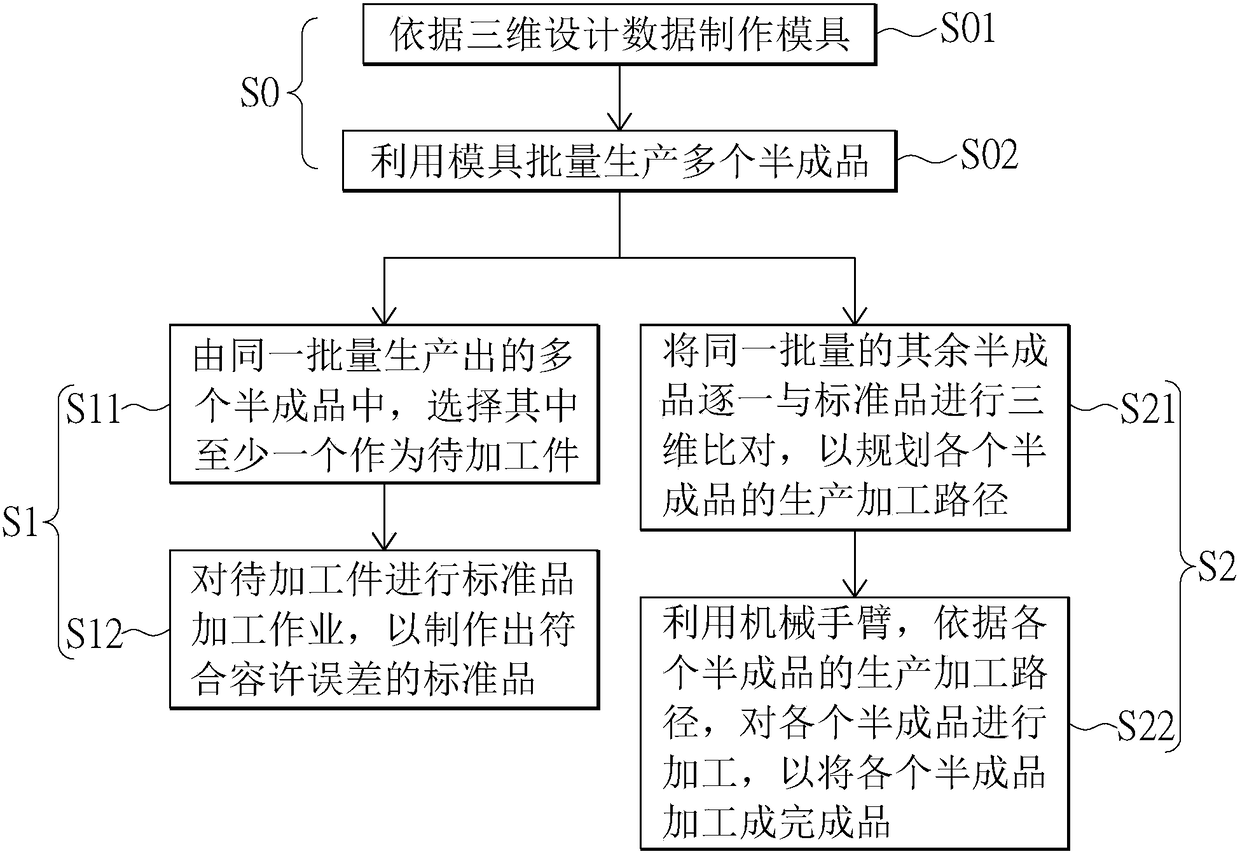

[0035] See figure 1 , Which is a schematic flow diagram of the workpiece processing method of the present invention. As shown in the figure, the workpiece processing method of the present invention includes the following steps:

[0036] Step S0 of mass production of semi-finished products:

[0037] Step S01: Make a mold based on the three-dimensional design data; and

[0038] Step S02: Use molds to mass produce multiple semi-finished products;

[0039] Step S1 of standard product production:

[0040] Step S11: Among the multiple semi-finished products produced in the same batch, at least one of them is selected as a part to be processed; and

[0041] Step S12: Perform a standard product processing operation on the workpiece to be processed to produce a standard product that meets an allowable error; and

[0042] Mass production production step S2:

[0043] Step S21: Perform a three-dimensional comparison of the remaining semi-finished products in the same batch with the standard products ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com