Self-insulation building block cutting device adopting wet cutting method

A self-insulating block and cutting device technology, which is applied in the field of construction machinery, achieves the effects of simple structure, reduced difficulty, and improved aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

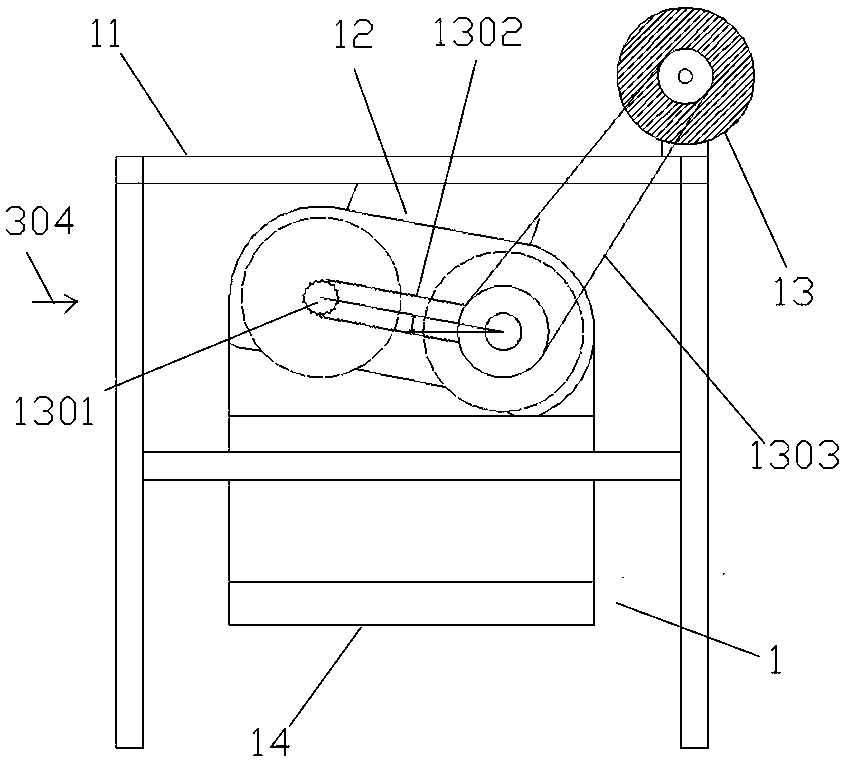

[0035] As shown in the figure: the embodiment of the present invention provides a self-insulating block cutting device using wet cutting, including a waste removal device 1 for trimming the top of the formed body and a device for vertically cutting the body. The cutting device 2 for straight slitting, the waste removal device 1 and the cutting device 2 are arranged sequentially above the track from the starting end to the rear process direction.

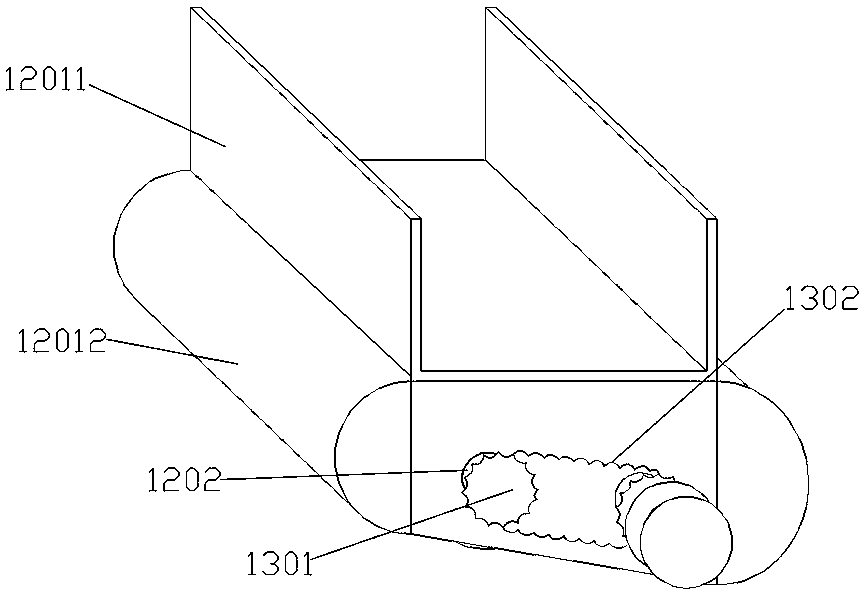

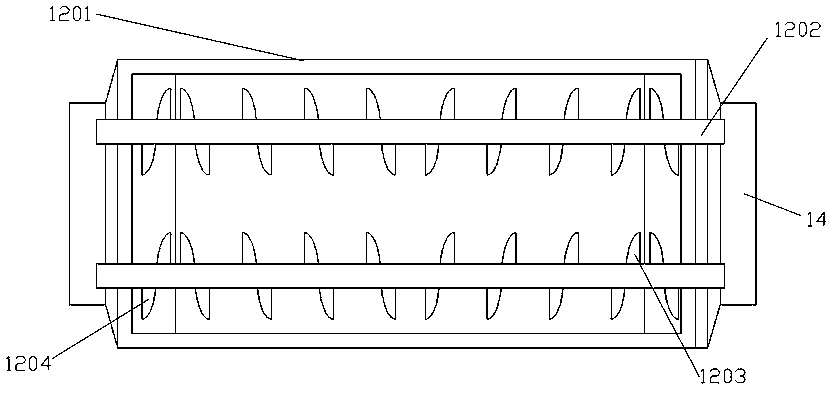

[0036]The top waste device 1 includes a frame 11, a top waste mechanism 12, a drive motor 13 and a lower hopper 14, and the top waste mechanism 12 includes a housing 1201, and the housing 1201 includes a base frame 12011 and is welded at its lower end. The outer casing 12012, the base frame 12011 is made of chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com