Cement mixing device for bridge construction

A technology of bridge construction and mixing device, applied in cement mixing device, mixing operation control device, clay preparation device, etc., can solve the problems of too much cement powder, too thin cement paddle, too much water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

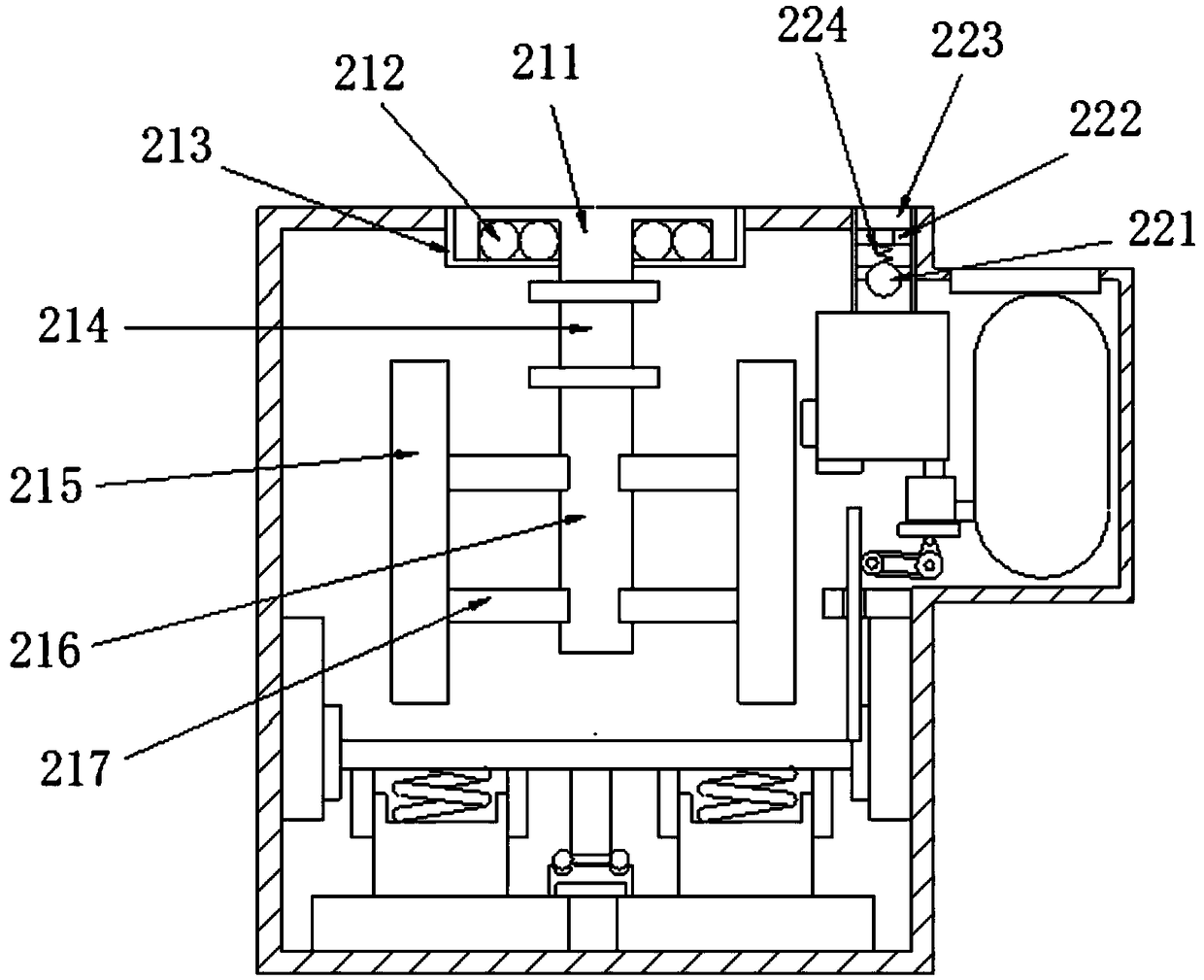

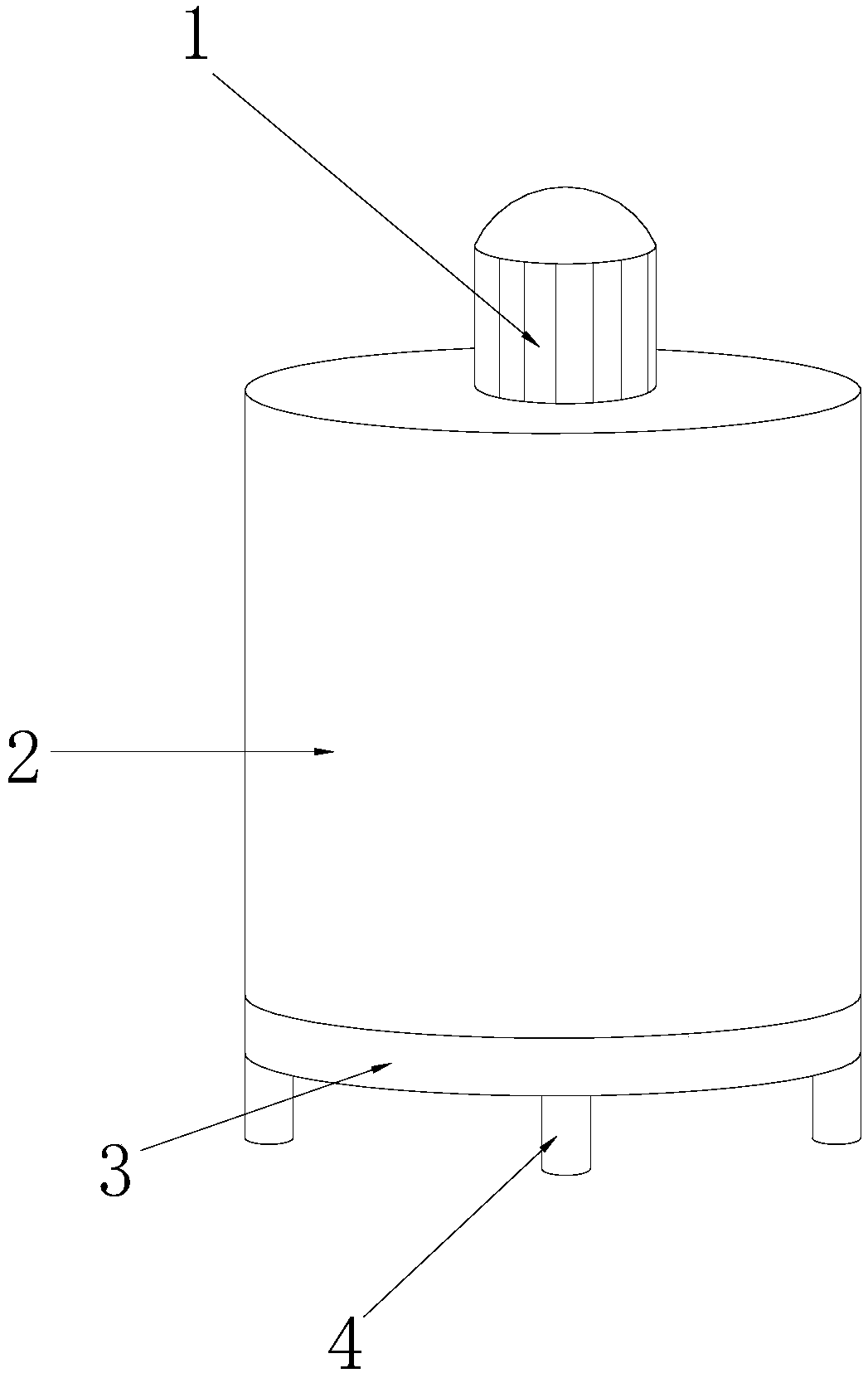

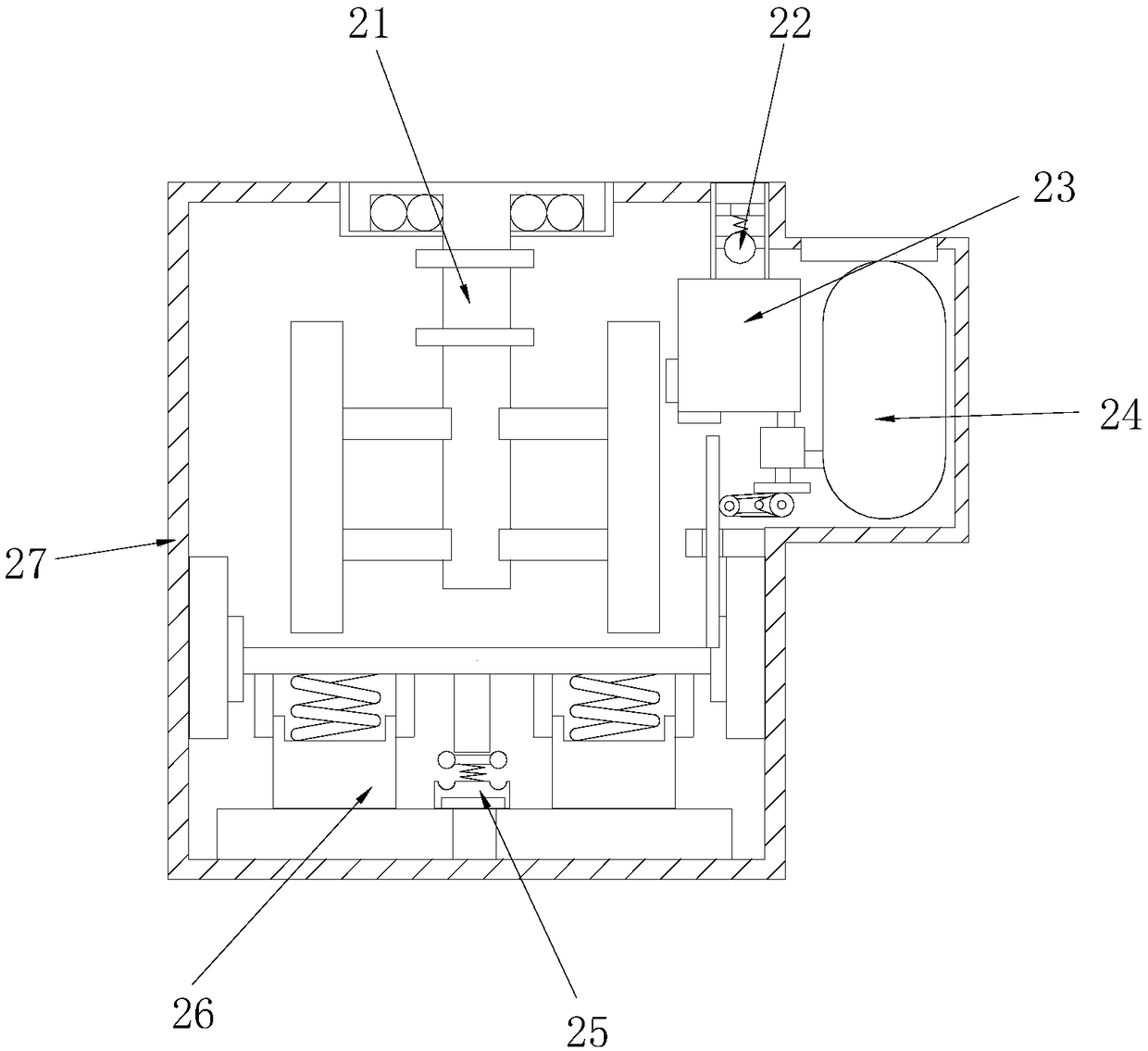

[0029] see Figure 1-Figure 8, the present invention provides a cement mixing device for bridge construction. Its structure includes a rotating machine 1, a body 2, a sealing ring 3, and a support foot 4. The bottom end of the rotating machine 1 is embedded in the top of the body 2, and the sealing ring 3 It is located at the bottom of the body 2 and is an integrated structure. The top of the supporting leg 4 is welded to the bottom of the body 2. The sealing ring 3 is located below the rotating machine 1. The body 2 includes a rotating mechanism 21, Anti-dust mechanism 22, material control mechanism 23, water adding mechanism 24, control module 25, press-down mechanism 26, casing 27, the top of the rotating mechanism 21 is vertically embedded in the top of the casing 27, the bottom of the anti-dust mechanism 22 Welded with the top of the material control mechanism 23, the water adding mechanism 24 is located on the right side of the material control mechanism 23, the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com