Brick cutter for construction site

A technology for cutting bricks and construction sites, applied to work accessories, manufacturing tools, stone processing tools, etc. It can solve the problems of hand injuries and inability to ensure accurate block breaking, and achieve the effect of avoiding shock injuries and easy cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

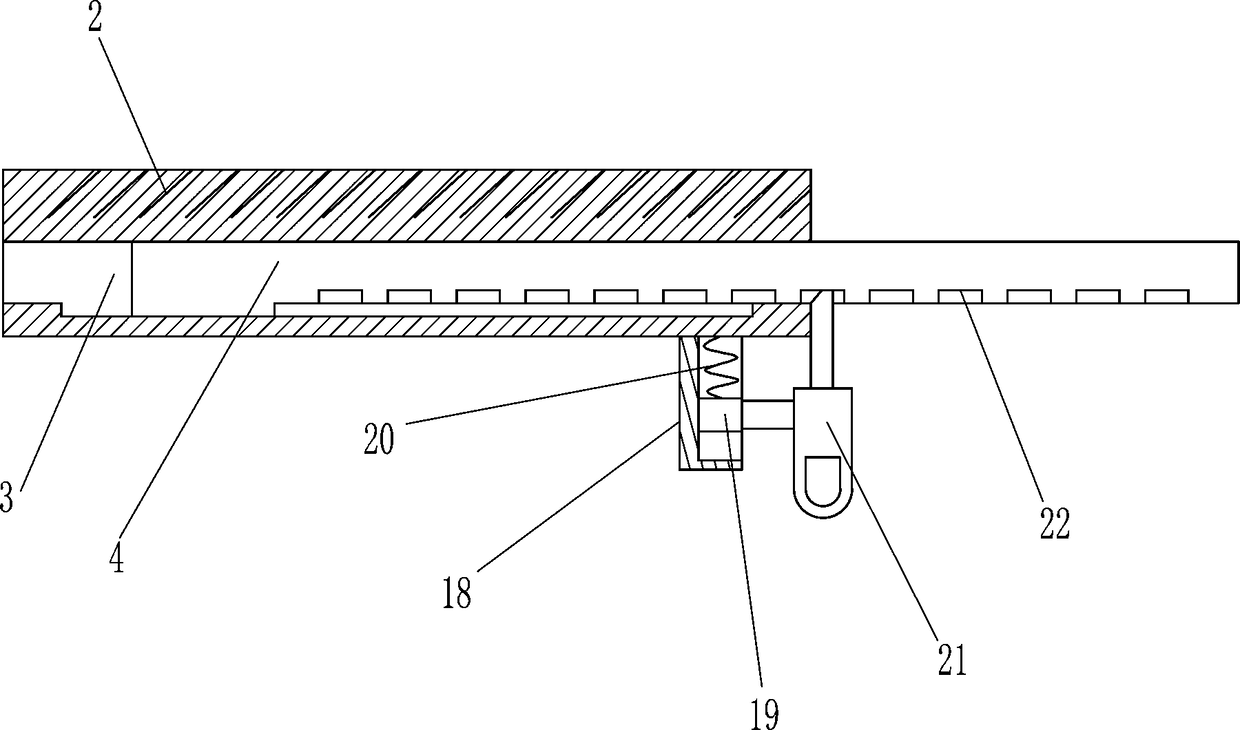

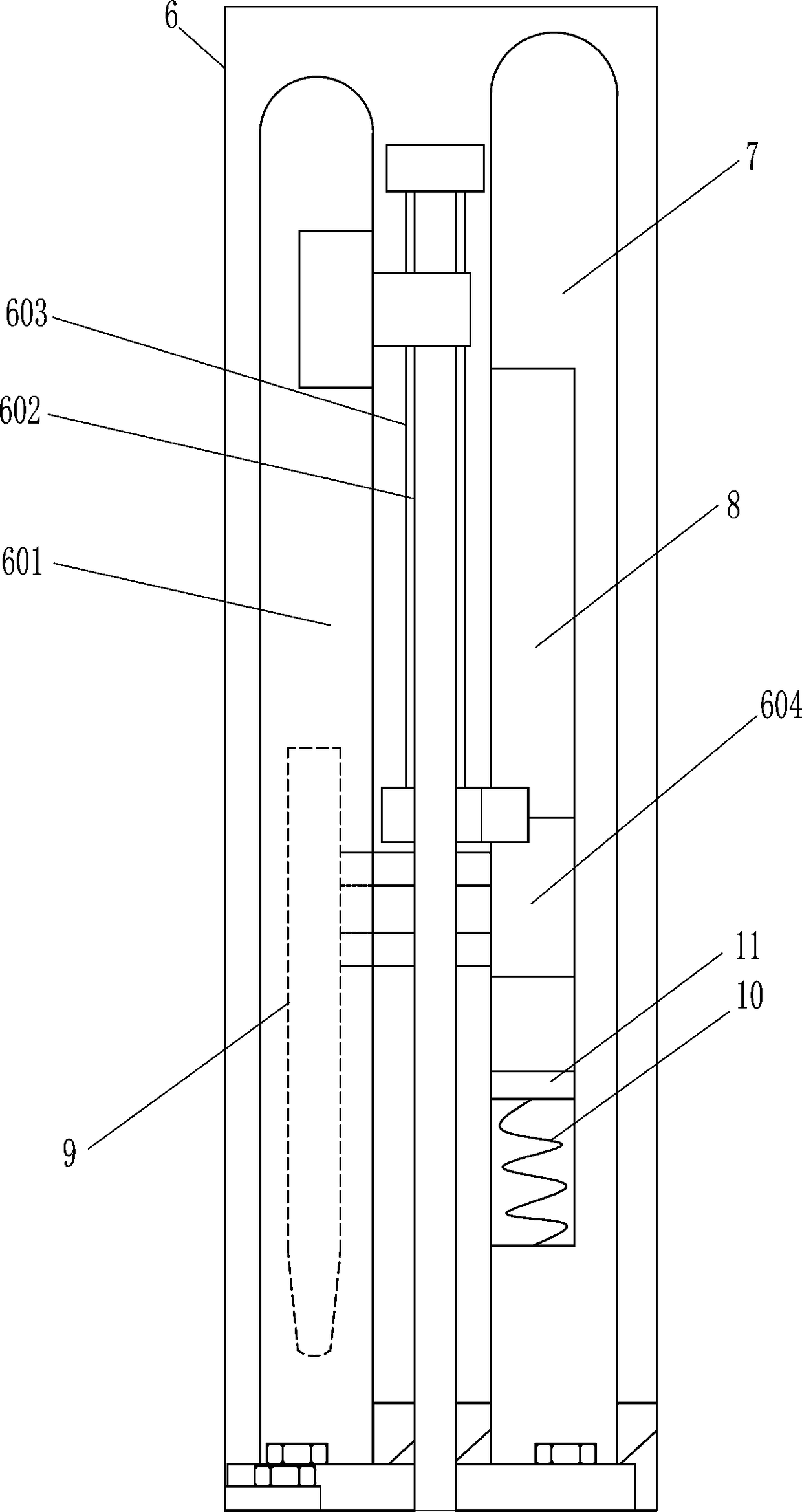

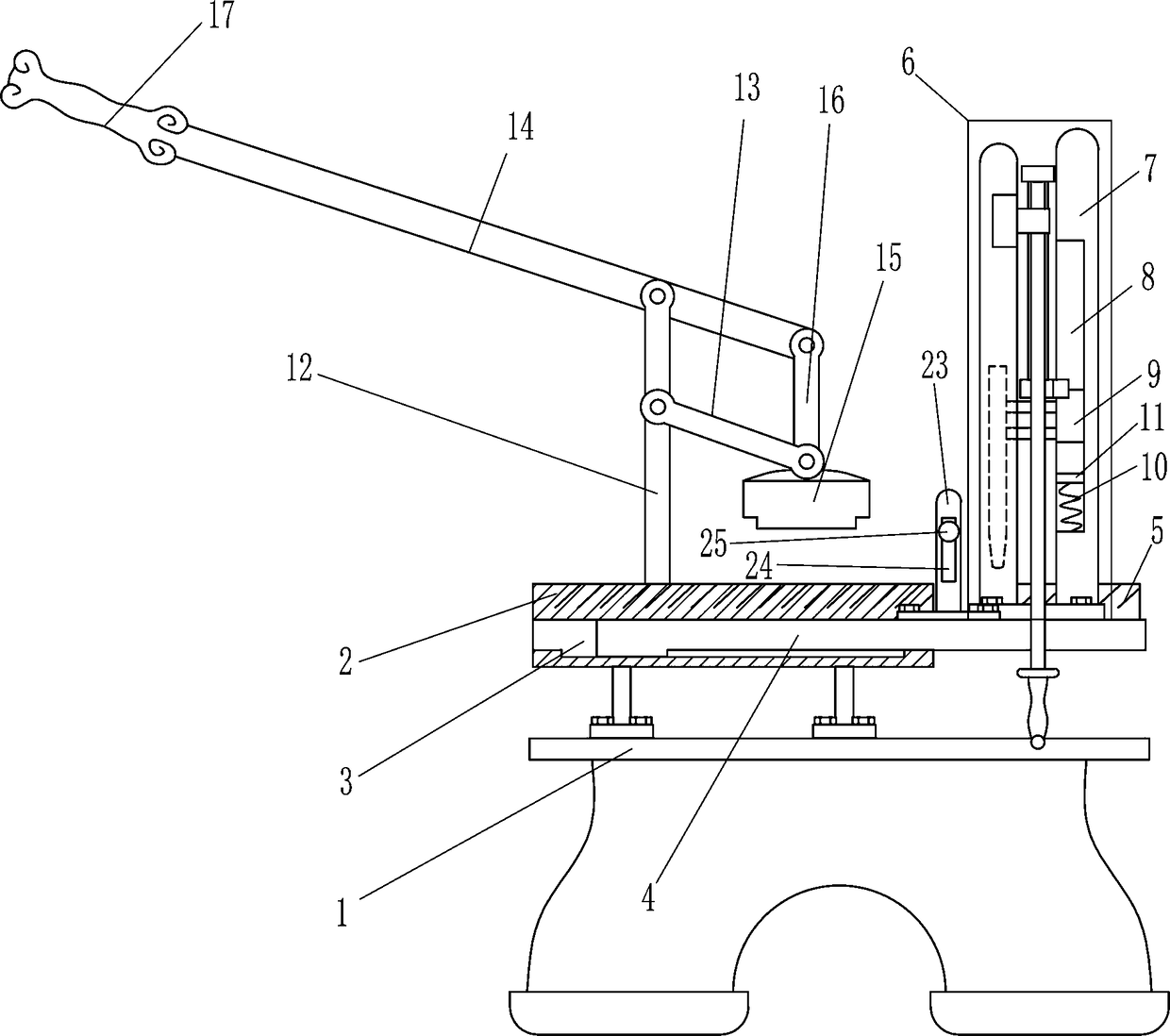

[0021] A kind of brick cutter for construction site, such as Figure 1-5 As shown, it includes a mounting base 1, a fixing plate 2, a sliding plate 4, a cutting plate 5 and a driving mechanism 6. A fixing plate 2 is provided on the left side of the top of the mounting base 1, and a first chute 3 is opened on the front side of the fixing plate 2. Slider 4 is slidably installed in a chute 3 , the rear side of the right side of the top of the slider 4 is provided with a cutting plate 5 , and the front side of the top right side of the slider 4 is provided with a driving mechanism 6 , and the driving mechanism 6 includes a first fixed rod 601 , rotating rod 602, the first connecting rod 603, the first slide block 604, the second fixed rod 7, the cutter 9, the first spring 10 and the push plate 11, the front side of the slide plate 4 top right side is provided with the first fixed rod 601, the top of the first fixed rod 601 is rotatably provided with a rotating rod 602, the front s...

Embodiment 2

[0023] A kind of brick cutter for construction site, such as Figure 1-5 As shown, it includes a mounting base 1, a fixing plate 2, a sliding plate 4, a cutting plate 5 and a driving mechanism 6. A fixing plate 2 is provided on the left side of the top of the mounting base 1, and a first chute 3 is opened on the front side of the fixing plate 2. Slider 4 is slidably installed in a chute 3 , the rear side of the right side of the top of the slider 4 is provided with a cutting plate 5 , and the front side of the top right side of the slider 4 is provided with a driving mechanism 6 , and the driving mechanism 6 includes a first fixed rod 601 , rotating rod 602, the first connecting rod 603, the first slide block 604, the second fixed rod 7, the cutter 9, the first spring 10 and the push plate 11, the front side of the slide plate 4 top right side is provided with the first fixed rod 601, the top of the first fixed rod 601 is rotatably provided with a rotating rod 602, the front s...

Embodiment 3

[0026] A kind of brick cutter for construction site, such as Figure 1-5As shown, it includes a mounting base 1, a fixing plate 2, a sliding plate 4, a cutting plate 5 and a driving mechanism 6. A fixing plate 2 is provided on the left side of the top of the mounting base 1, and a first chute 3 is opened on the front side of the fixing plate 2. Slider 4 is slidably installed in a chute 3 , the rear side of the right side of the top of the slider 4 is provided with a cutting plate 5 , and the front side of the top right side of the slider 4 is provided with a driving mechanism 6 , and the driving mechanism 6 includes a first fixed rod 601 , rotating rod 602, the first connecting rod 603, the first slide block 604, the second fixed rod 7, the cutter 9, the first spring 10 and the push plate 11, the front side of the slide plate 4 top right side is provided with the first fixed rod 601, the top of the first fixed rod 601 is rotatably provided with a rotating rod 602, the front si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com