Fault detection method and device

A fault detection and identification technology, applied in manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc., can solve the problems of printing failure, long time consumption, low efficiency, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

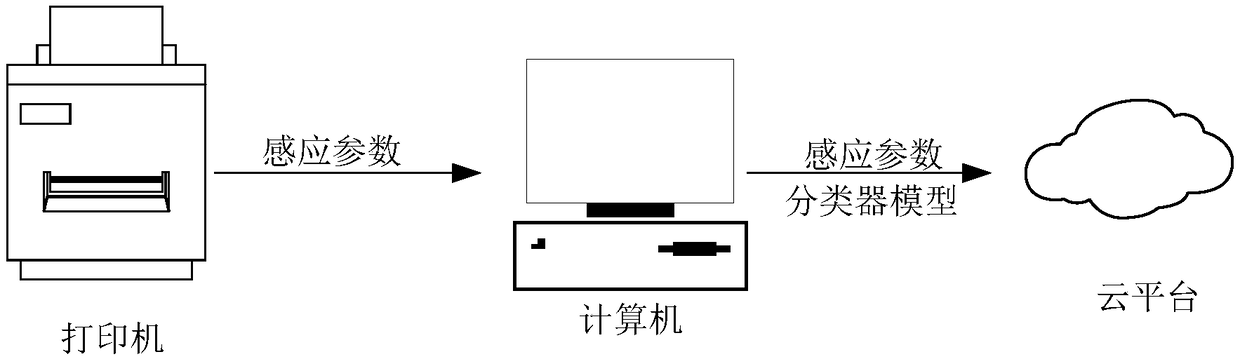

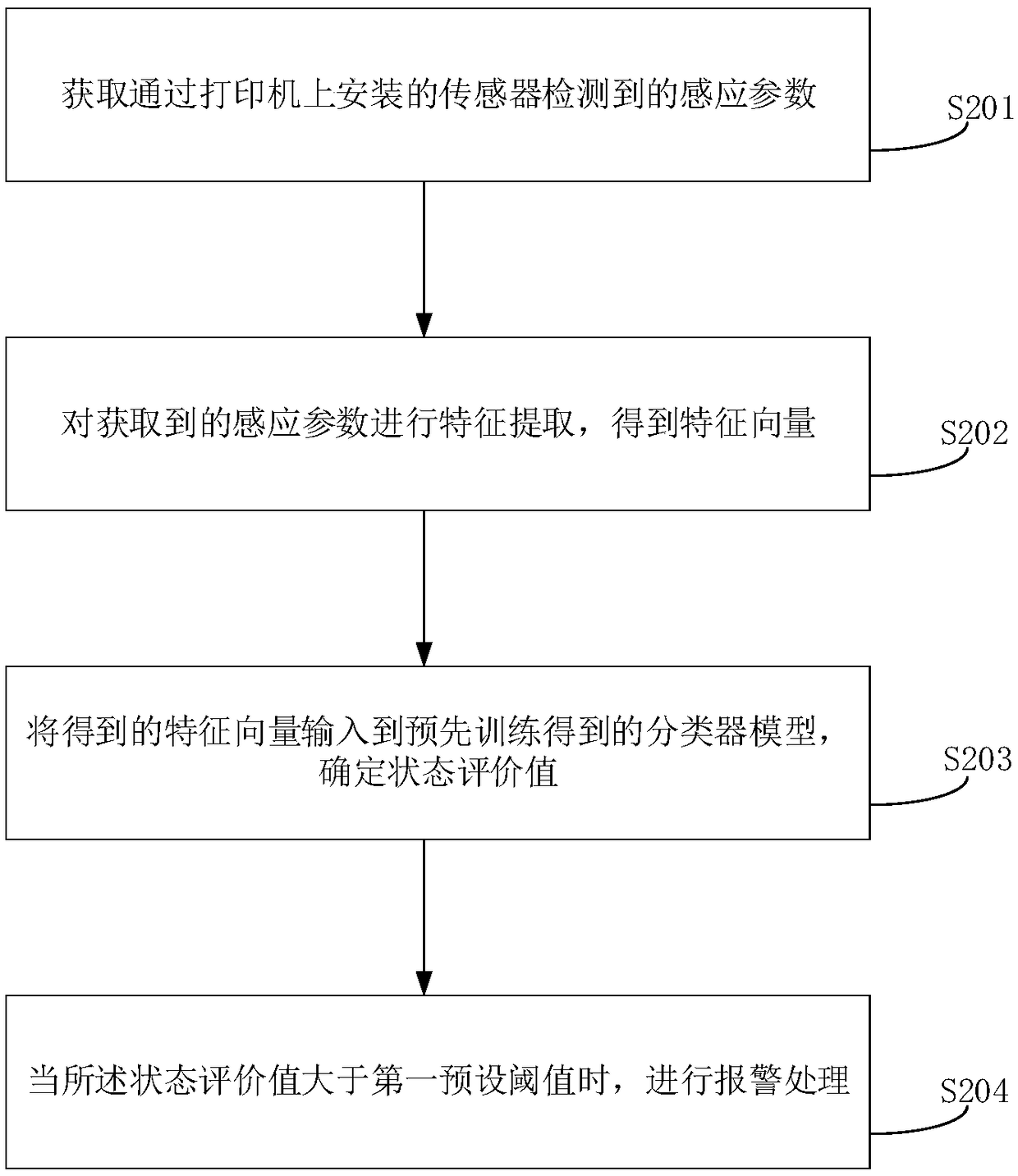

[0069] see figure 2 As shown, it is a schematic flowchart of a fault detection method and device provided in the embodiment of the present application, including the following steps:

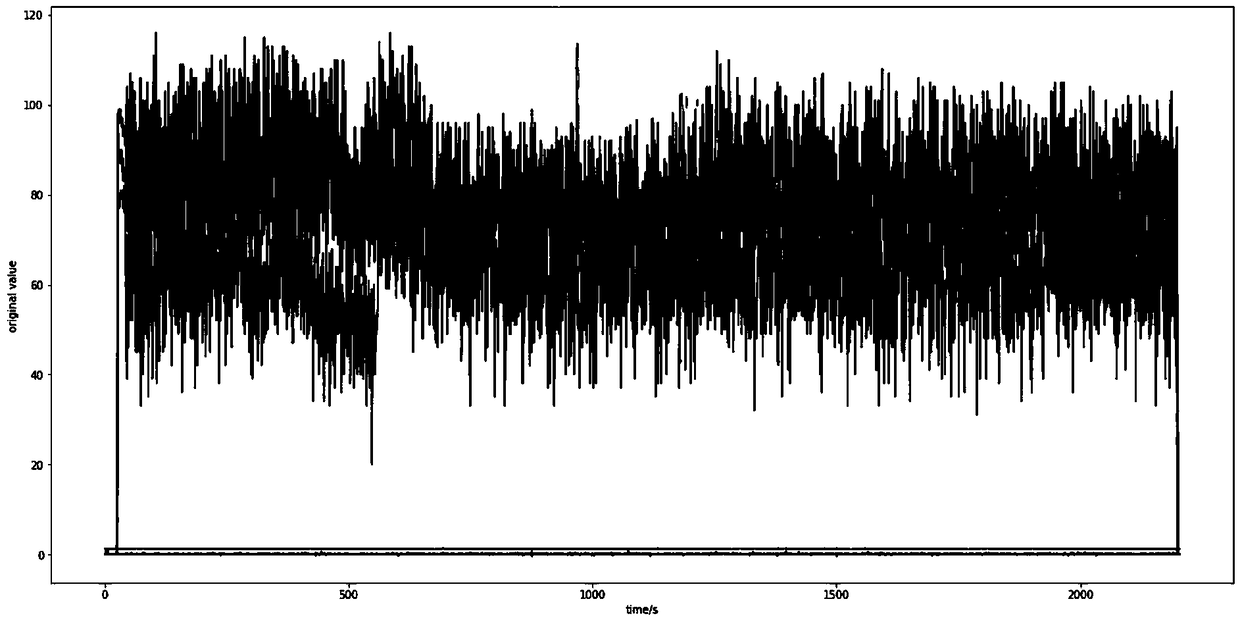

[0070] S201. Obtain a sensing parameter detected by a sensor installed on the printer.

[0071] In a possible implementation manner, the printer may be a 3D printer; the sensor may be a vibration sensor and an acceleration sensor; the sensing parameter may be a frequency detected by the vibration sensor and an acceleration detected by the acceleration sensor.

[0072] Before obtaining the sensing parameters through the sensor, the sensor can be debugged first, for example, the sensitivity of the sensor can be debugged.

[0073] In the embodiment of the present application, a vibration sensor and an acceleration sensor are used, but in practical applications, it is not limited to these two sensors. For example, other optional sensors, such as temperature and humidity sensors, may also be used....

Embodiment 2

[0126] The embodiment of the present application provides a fault detection device, referring to Figure 7 As shown, it is a schematic diagram of the structure of the fault monitoring device 700 provided by the embodiment of the present application. The device 700 includes: an acquisition module 701 , a feature extraction module 702 , a determination module 703 and an alarm module 704 .

[0127] Specifically, the obtaining module 701 is configured to obtain sensing parameters detected by sensors installed on the printer, wherein the sensing parameters are used to reflect the current working state of the printer;

[0128] A feature extraction module 702, configured to perform feature extraction on the acquired sensing parameters to obtain a feature vector;

[0129] A determining module 703, configured to input the obtained feature vectors into a pre-trained classifier model to determine a state evaluation value, wherein the state evaluation value is used to reflect the possibil...

Embodiment 3

[0149] like Figure 8 As shown, a schematic structural diagram of an electronic device 800 provided in Embodiment 4 of the present application includes: a processor 801, a memory 802, and a bus 803;

[0150] The above-mentioned memory 802 stores machine-readable instructions executable by the above-mentioned processor 801 (for example, including Figure 7 The acquisition module 701, the feature extraction module 702, the determination module 703, and the execution instructions corresponding to the alarm module 704, etc.), when the electronic device 800 is running, the above-mentioned processor 801 and the above-mentioned memory 802 communicate through the bus 803, and the above-mentioned machine can When the read instruction is executed by the above-mentioned processor 801, the following processing is performed:

[0151] acquiring sensing parameters detected by sensors installed on the printer, wherein the sensing parameters are used to reflect the current working state of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com