Flat comb roller needle surface cleaning device

A technology of cleaning device and flat carding, which is applied in deburring devices, textile and papermaking, fiber processing, etc., can solve the problems of reducing the depilation effect of the flat carding roller, hidden dangers to the health of operators, and the failure of the flat carding function, so as to ensure the stripping effect of the flat carding roller. Gross effect, flexible action, small device effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

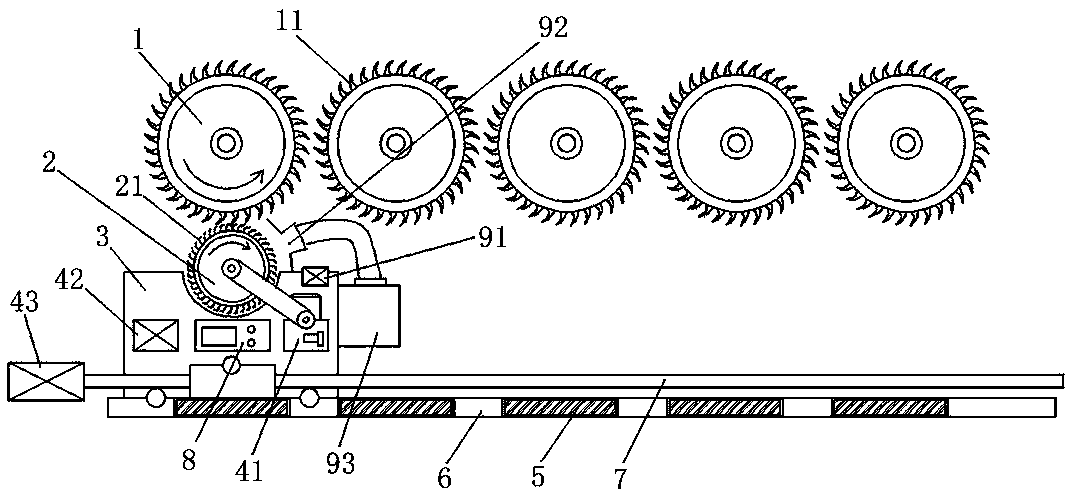

[0013] The structure and working principle of a flat comb roller needle surface cleaning device provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0014] Such as figure 1 Shown is a schematic structural view of a flat comb roller needle surface cleaning device provided by the present invention. The structure constituting the needle surface cleaning device of the flat comb roller includes a power roller shaft 2 arranged parallel to the roller shaft 1, and the surface of the power roller shaft 2 is provided with an elastic metal card clothing 21, and the metal needle length of the elastic metal card clothing 21 is not less than The needle surface teeth of the flat comb roller are deep and the inclination angles of the metal needles and the pin teeth 11 of the flat comb roller are consistent, and the tangential direction of the movement of the power roller shaft 2 in contact with the roller shaft 1 is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com