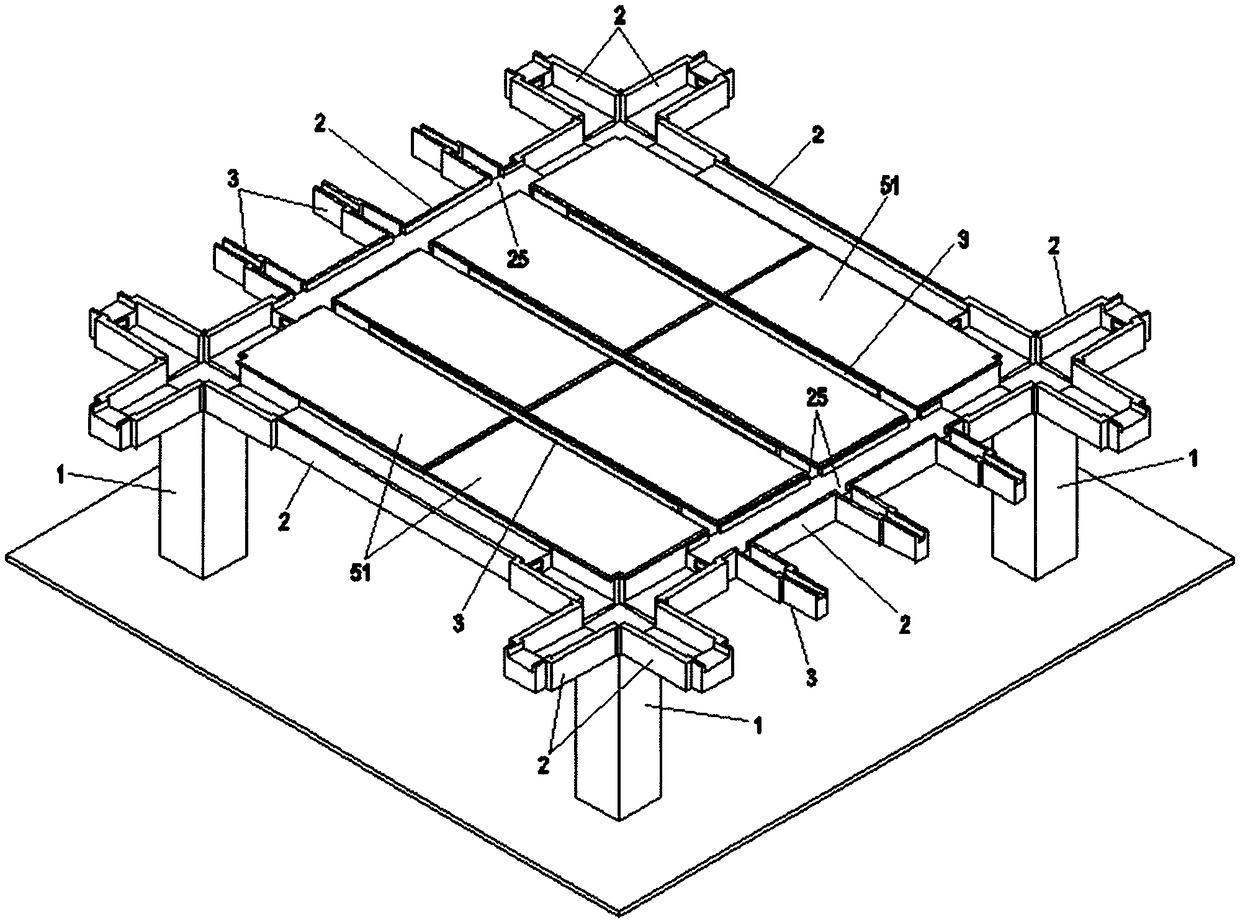

Novel prefabricated frame structure

A frame structure, a new type of technology, applied in the direction of building components, building structures, building materials, etc., can solve the problems of heavy construction work, limited prefabricated parts, shortened construction period, etc., to reduce construction waste, reduce noise and Dust pollution and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

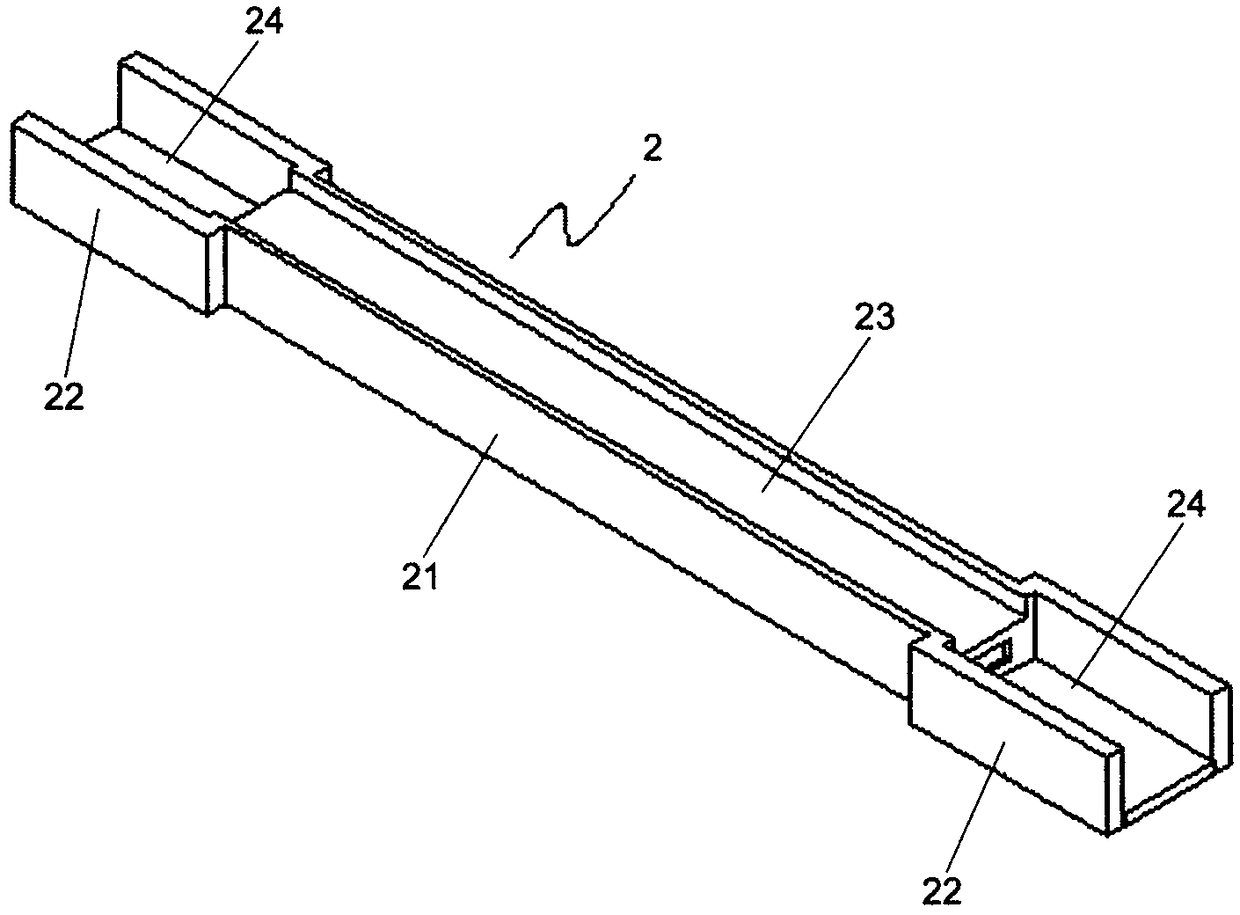

[0039] Embodiment one, as figure 2 As shown, the width of the two ends 22 of the main girder 2 is larger than the width of the middle part 21, and the middle part 21 and the end part 22 are connected in a stepped shape. The tops of the middle part 21 of the main beam 2 and the tops of both ends 22 are respectively provided with recesses 23 and 24, wherein the recess 23 of the middle part 21 is relatively shallow, and the recess 24 of the end part 22 is deep and penetrates to the end surface of the main beam 2. 21 both sides and end 22 both sides are of the same height. When pouring concrete on the floor, the recesses 23 and 24 at the top of the main beam 2 are also cast-in-place concrete to form the cast-in-place part of the main beam 2 .

Embodiment 2

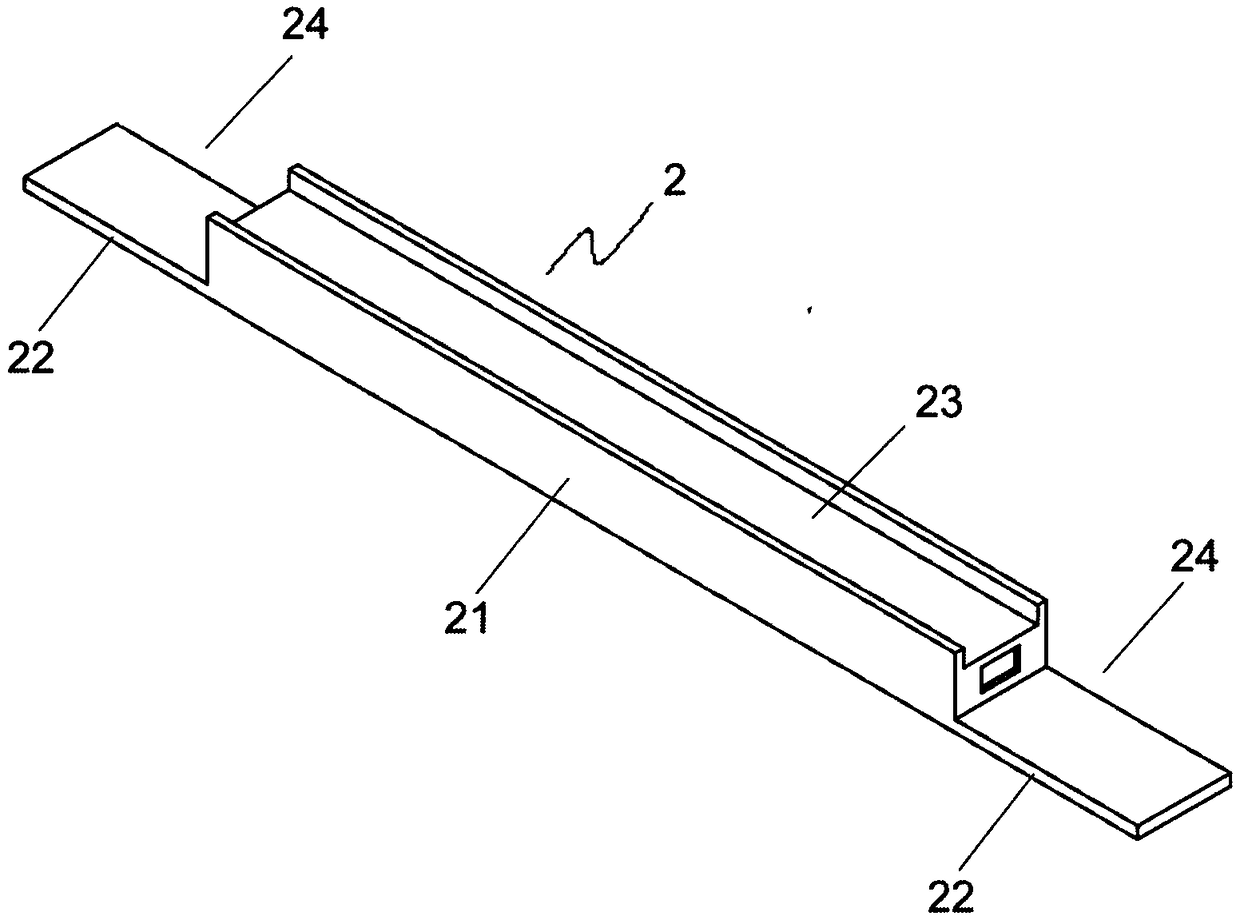

[0040] Embodiment two, such as image 3 As shown, different from the first embodiment of the main beam, the width of the two ends 22 of the main beam 2 is equal to the width of the middle part 21, and the height of both sides of the end 22 is much lower than the height of both sides of the middle part 21, so the end A small amount of formwork is required on both sides of 22 for sealing.

[0041] Similarly, in the present invention, the secondary beam 3 can also adopt the following two structural modes:

[0042] Embodiment one, as Figure 4 As shown, the widths of the two ends 32 of the secondary beam 3 are larger than the width of the middle part 31 , and the middle part 31 and the end parts 32 are connected in steps. The tops of the middle part 31 of the secondary beam 3 and the tops of both ends 32 are respectively provided with recesses 33 and 34, wherein the recess 33 of the middle part 31 is relatively shallow, and the recess 34 of the end part 32 is relatively deep and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com