Special-shaped steel column concrete filling construction method and concrete

A construction method and concrete technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of difficult pouring and high pouring cost, and achieve the effect of reducing construction cost, reducing construction time and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

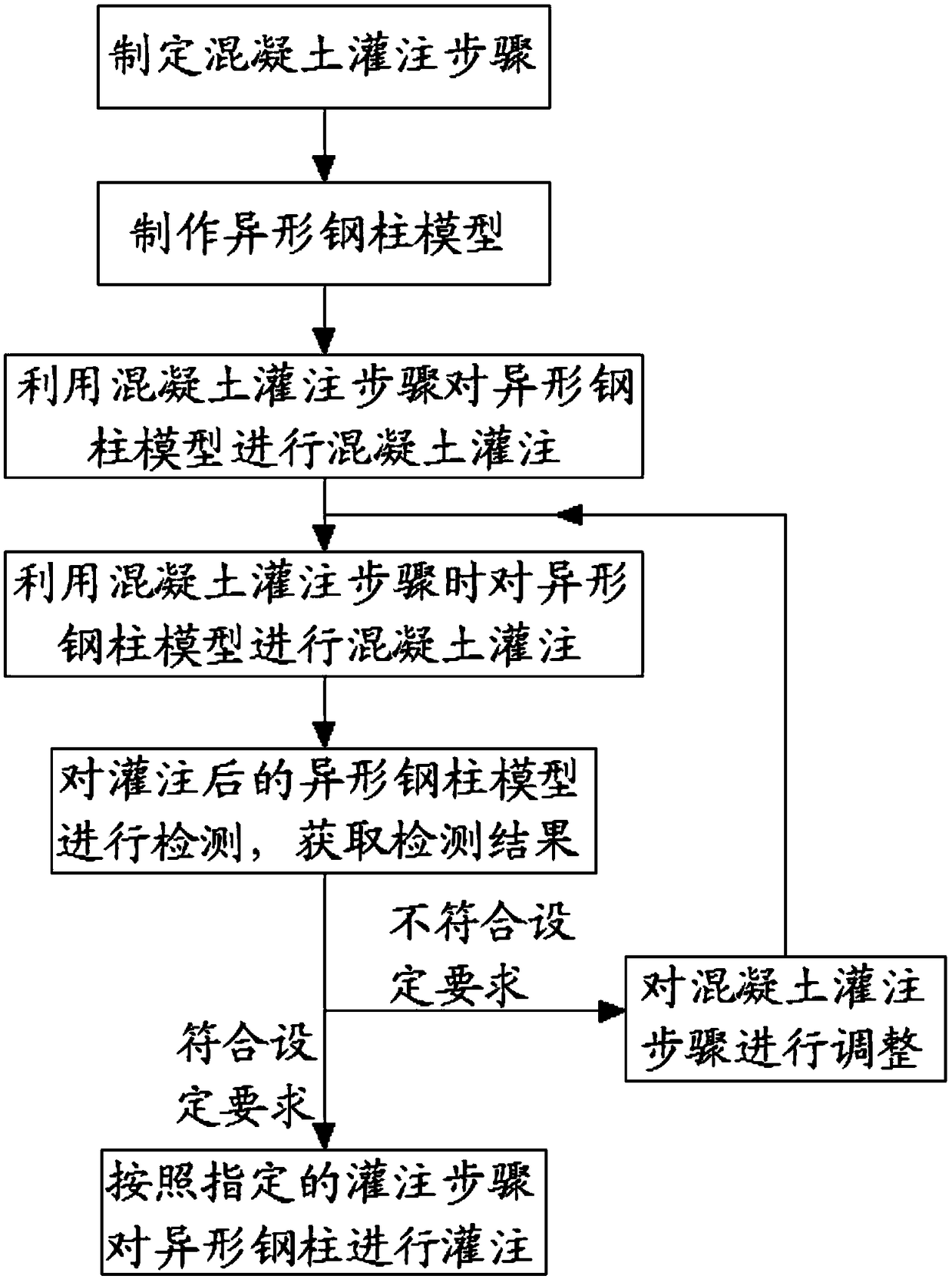

[0042] This embodiment discloses a special-shaped steel column concrete pouring construction method, such as image 3 shown, image 3 This is the flow chart of the construction method provided in this embodiment. The described construction method includes the following steps:

[0043] S1: formulate concrete pouring steps;

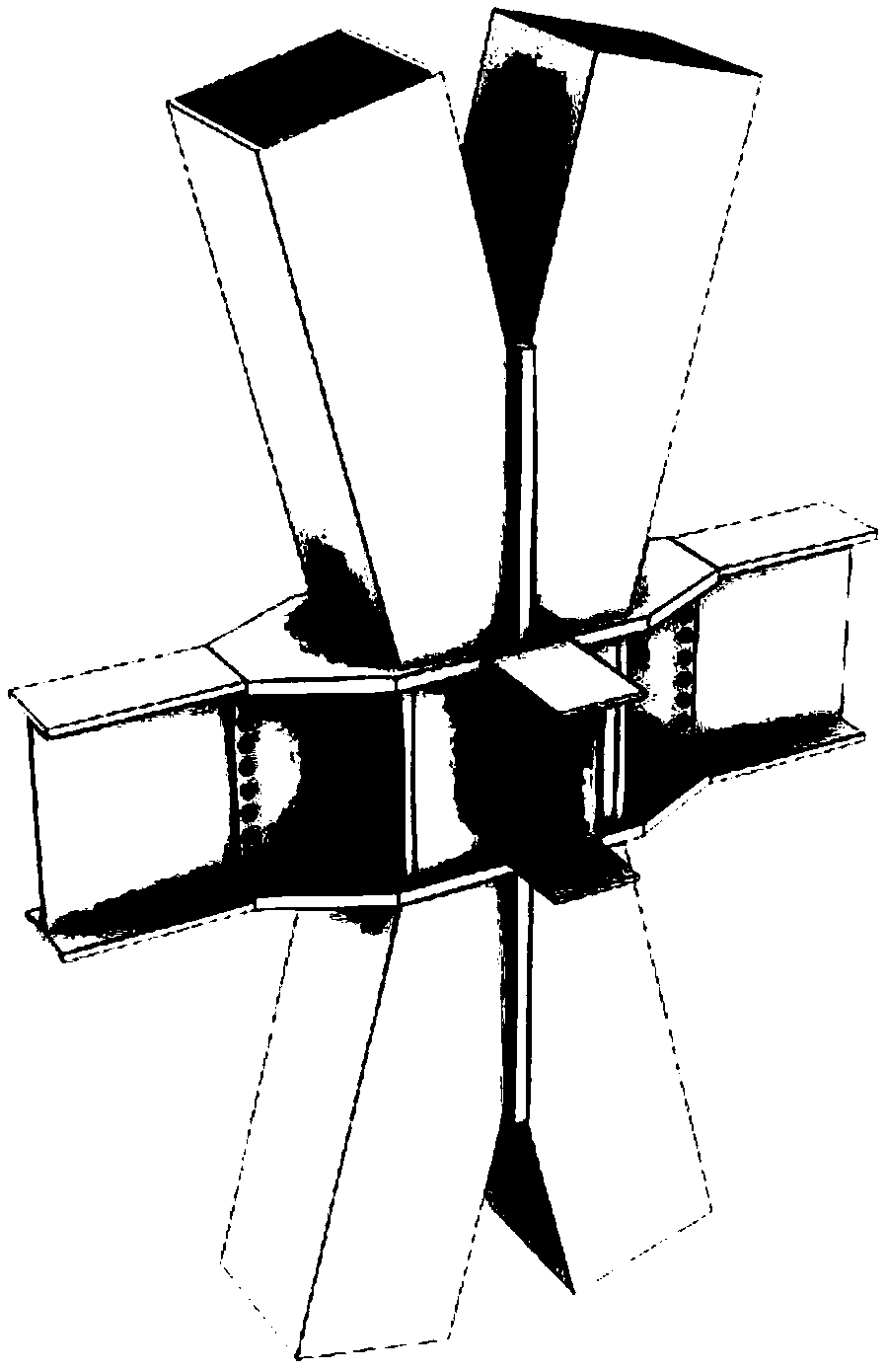

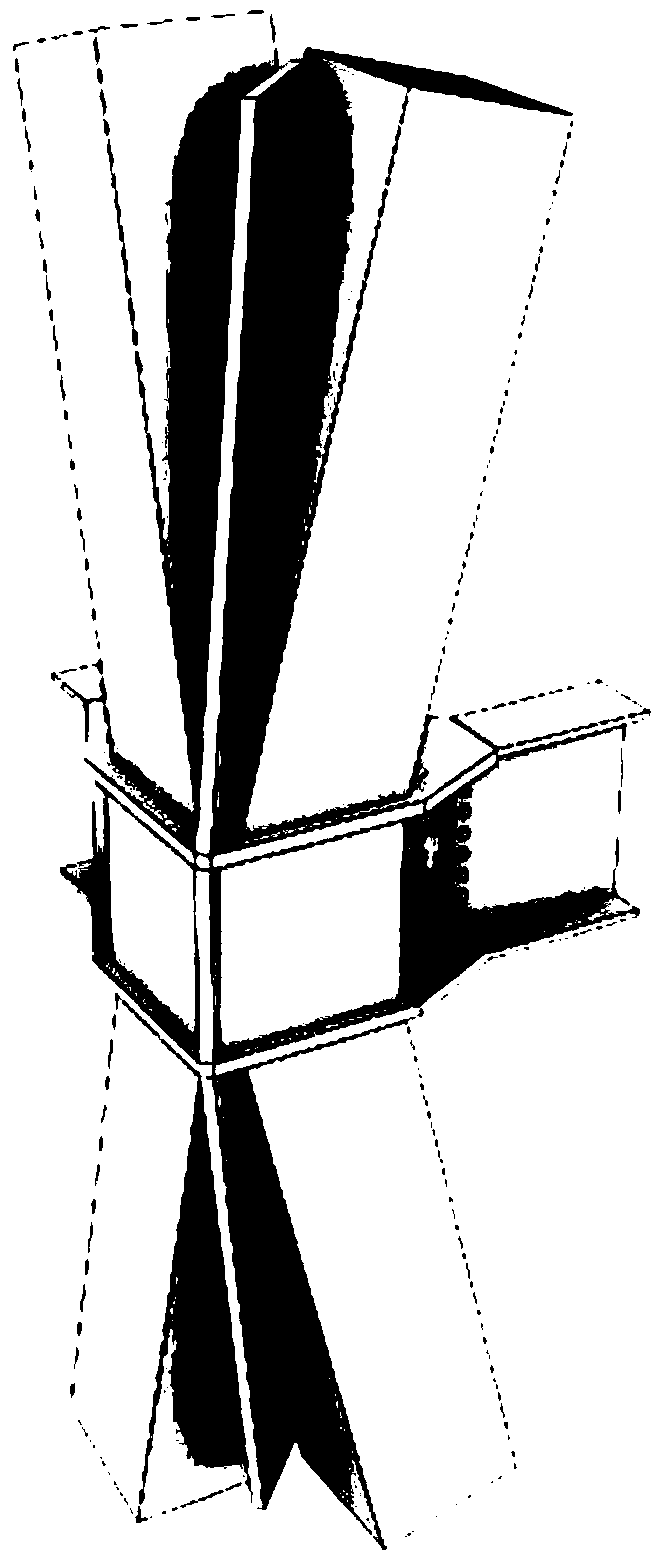

[0044] S2: Make a special-shaped steel column model;

[0045] For S2, since the skew-grid steel structure contains a plurality of the special-shaped steel columns, it is not practical to manufacture the entire skew-grid steel structure for simulation tests. Therefore, one or more of many special-shaped steel columns can be selected as a reference to make the special-shaped steel column model. Of course, several representative ones can also be selected according to the shape of the special-shaped steel column. For example, the special-shaped steel column includes a K-shaped steel column and an X-shaped steel column, so one K-shaped steel column can be pr...

Embodiment 2

[0062] Due to the high difficulty of pouring the special-shaped steel column described in Example 1, the existing self-compacting concrete is difficult to meet the pouring requirements for the special-shaped steel column. Therefore, this embodiment also provides a concrete for pouring the special-shaped steel column, the concrete can flow better in the inner space of the special-shaped steel column, so as to avoid the occurrence of failure due to inability to vibrate or insufficient vibration. Defects such as voids, honeycombs and pockmarks are produced. The concrete includes the following components:

[0063]

[0064] The flow performance of the concrete prepared by the above content is increased, and the defect of poor flowability of the existing concrete is overcome, so that it can be applied to the special-shaped steel column in Example 1, and can also be used for difficult or even impossible to pour. In the structural part, defects such as voids, honeycombs and pockma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com