Well cementation tubular column and well cementation method

A cementing and tubing string technology, applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve problems such as difficult to estimate accurately, difficult to accurately grasp the volume of drilling fluid, etc., to improve the success rate and the effect of effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

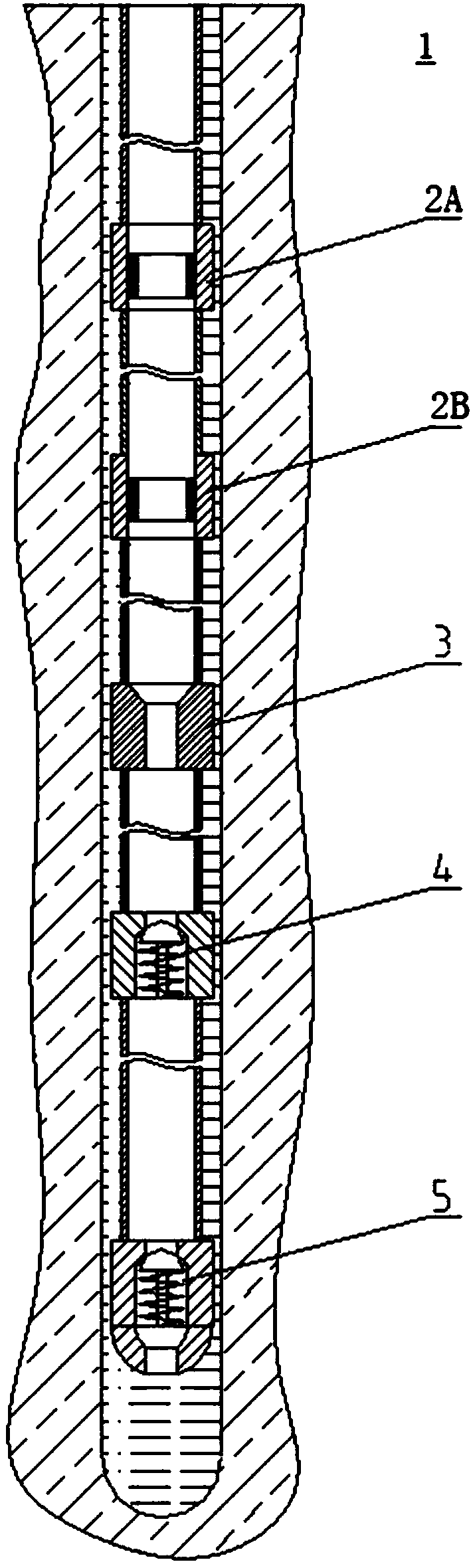

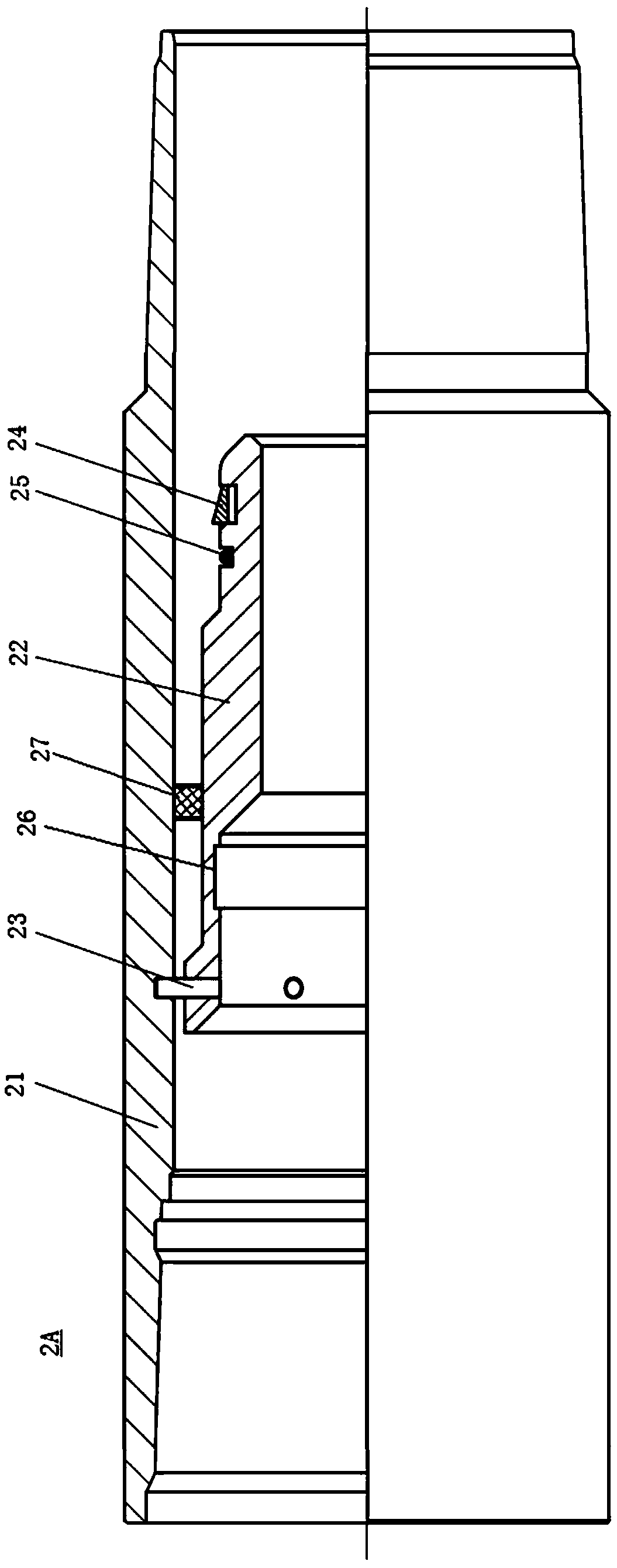

[0023] Such as figure 1 As shown, the cementing string 1 includes a bumper seat 3 and a positioning mechanism located upstream of the bumper seat 3 . The cementing string 1 may only include one positioning mechanism, or may include multiple positioning mechanisms, for example, may include two positioning mechanisms 2A, 2B (see figure 1 ). The positioning mechanism itself is set at a certain position of the cementing string 1, for example, the distance between the positioning mechanism and the wellhead is predetermined, that is, the downhole depth where the positioning mechanism is located is certain. In this case, when the cementing plug used to separate the cement slurry and the replacement fluid reaches the determined position of the positioning mechanism, the positioning mechanism sends a positioning signal in response to the arrival of the cementing plug. figure 1 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com