Oil gas pipeline automatic maintenance robot

A technology of oil and gas pipelines and robots, applied in pipeline systems, manipulators, mechanical equipment, etc., can solve problems such as troublesome pipeline maintenance, oil and gas leakage environment, pollution, etc., and achieve the effects of avoiding pollution, increasing weight, and reducing buoyancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

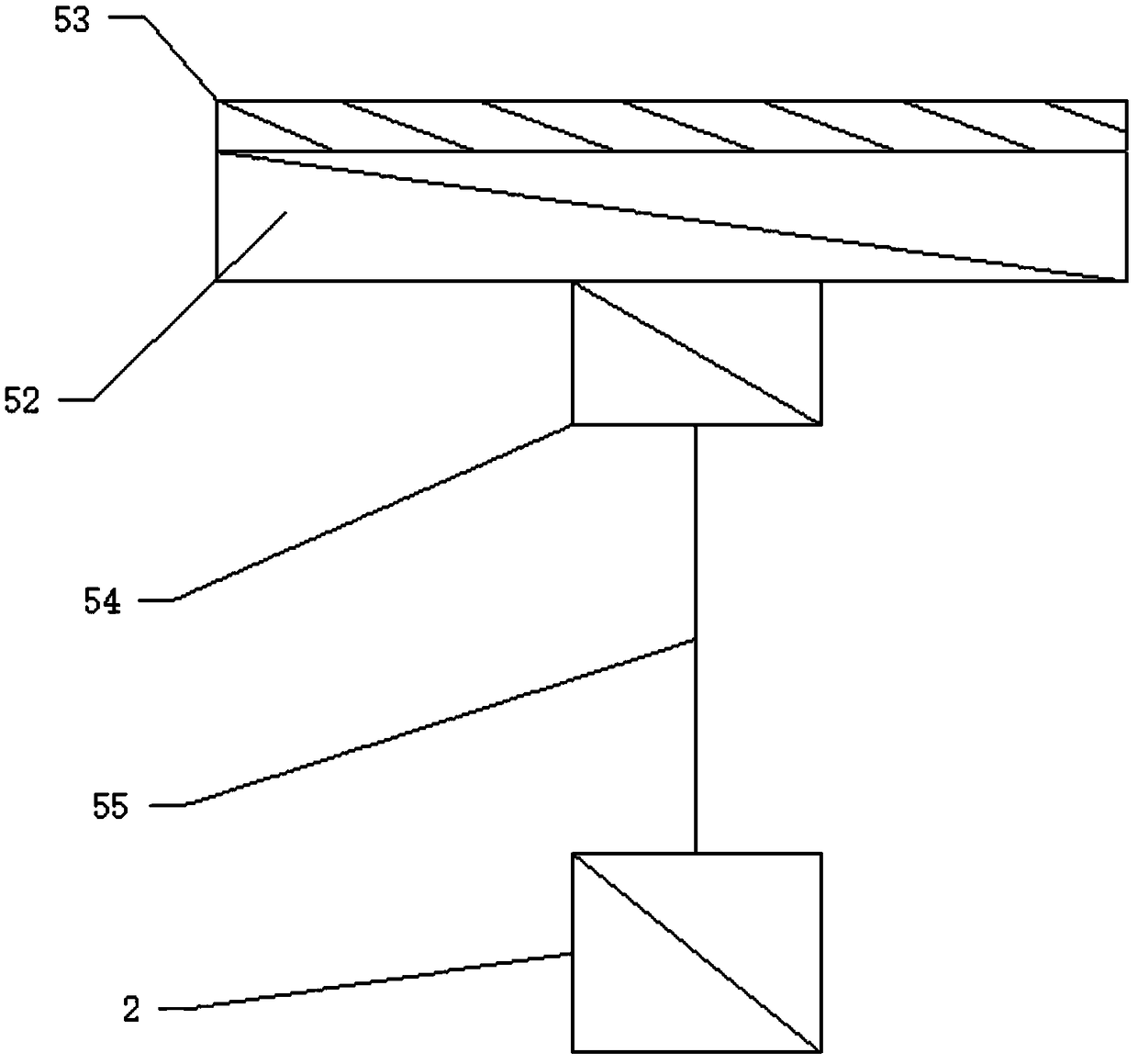

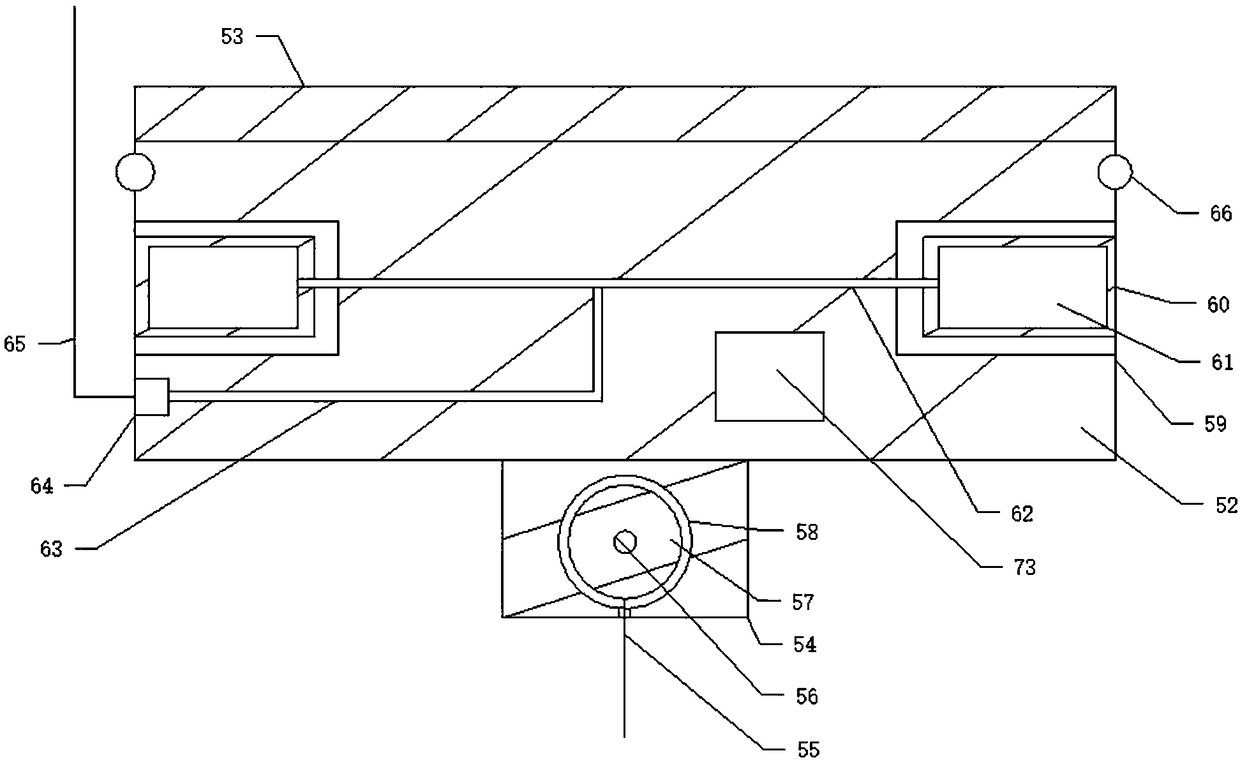

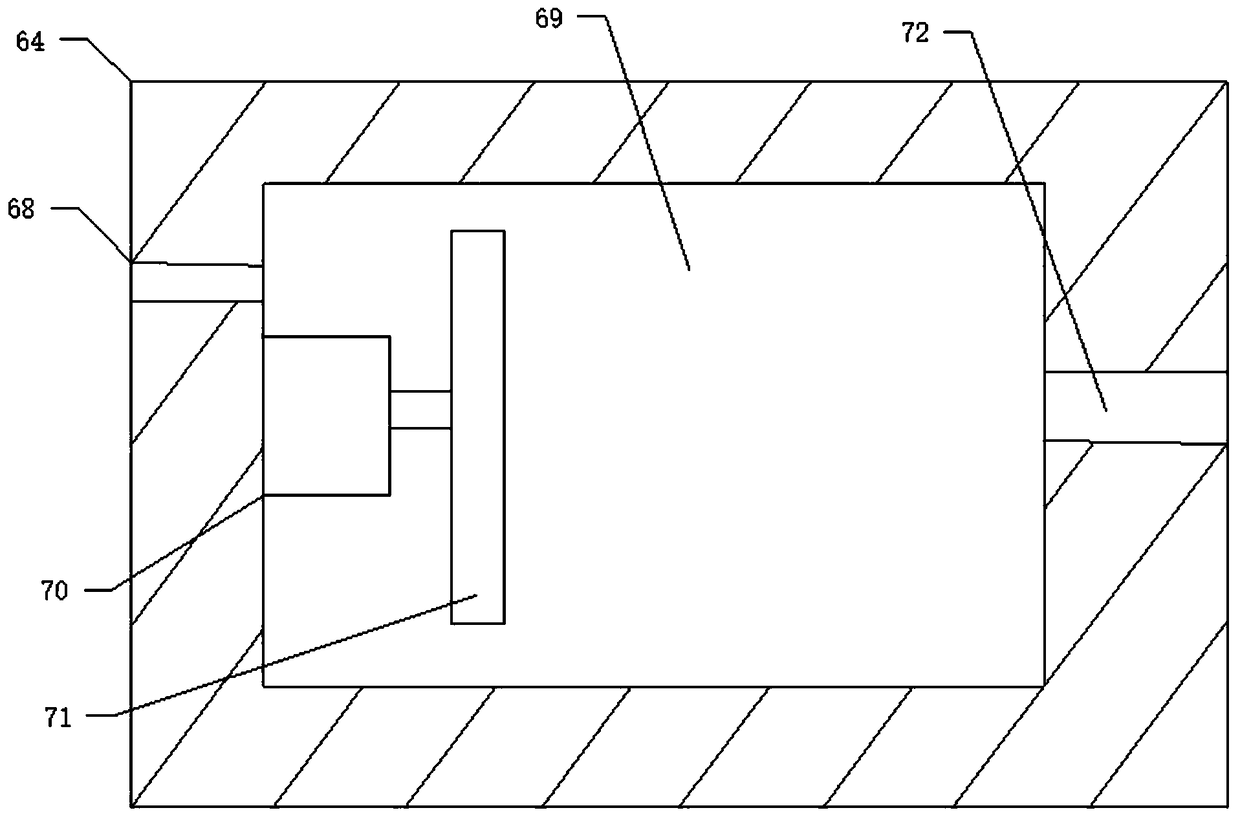

[0038] Such as Figure 1 to Figure 10 As shown, an oil and gas pipeline automatic maintenance robot includes pipelines 1 connected side by side, and a floating body 52. A solar panel 53 is arranged on the top of the floating body 52, and a solar panel 53 is arranged on the floating body 52. There is an inflated air bag 60, a storage battery 73 is arranged in the floating body 52, a pulling body 54 is also arranged on the floating body 52, and a rotating pull rope runner 57 is arranged in the pulling body 54, so A pull cord 55 is arranged on the pull cord runner 57 , and a cable connected to the battery 73 is arranged inside the pull cord 55 .

[0039] The pipelines 1 are arranged side by side on the bottom of the seabed, 7, including a floating body 52, which can float on the sponge, and a solar cell panel 53 is arranged on the floating body 52, so that the solar cell can pass through The panels 53 further generate electricity, and a battery 73 is arranged on the floating b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com