Ladle-lifting and material-dumping control device for holding furnace

A technology for control devices and hybrid furnaces, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve problems such as safety hazards, personal electric shock hazards, and switch damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

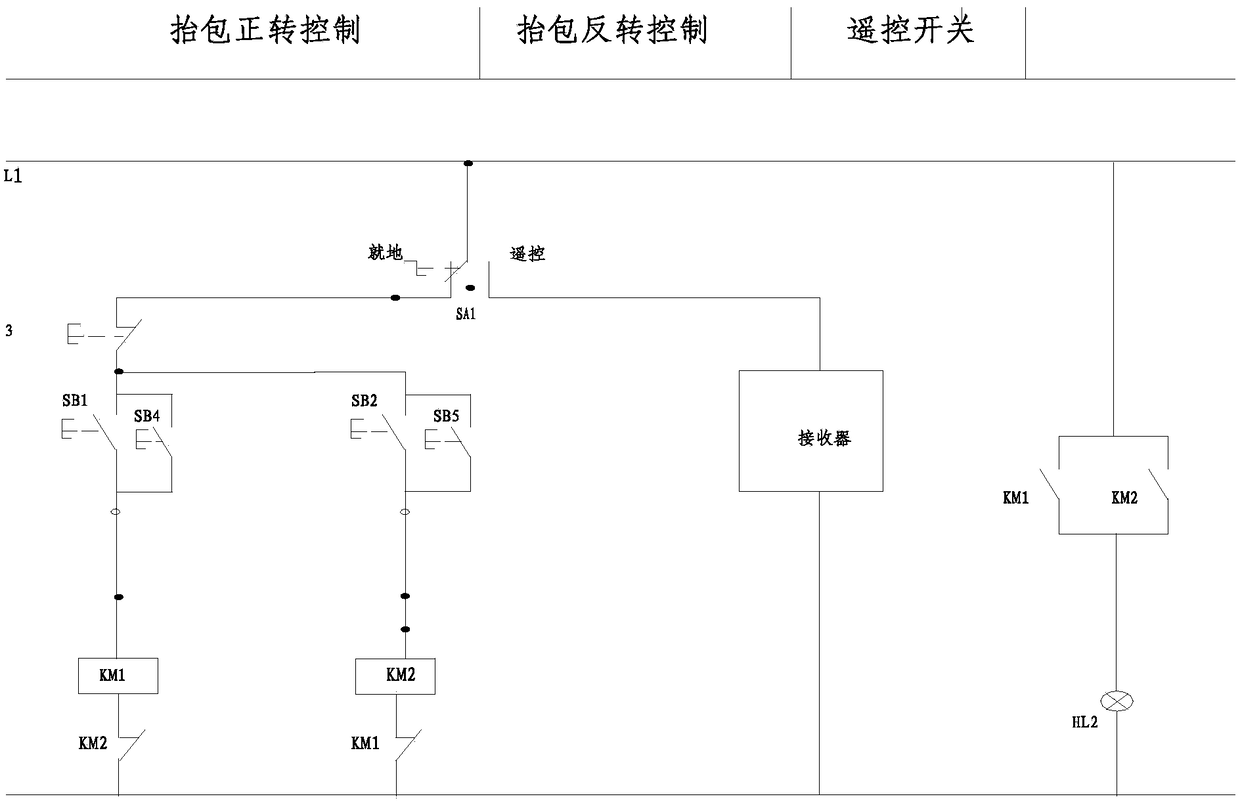

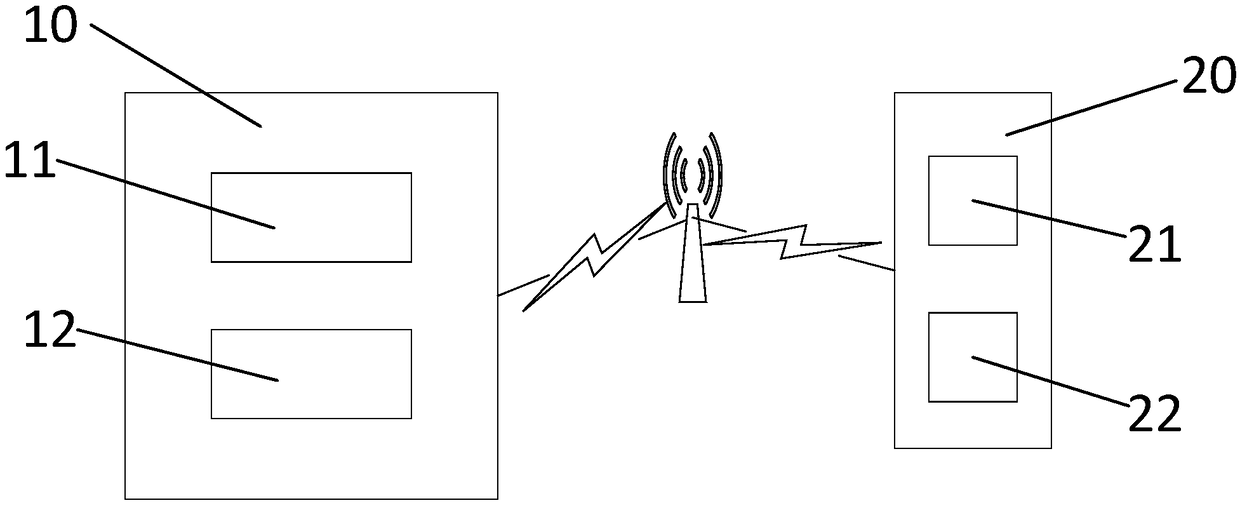

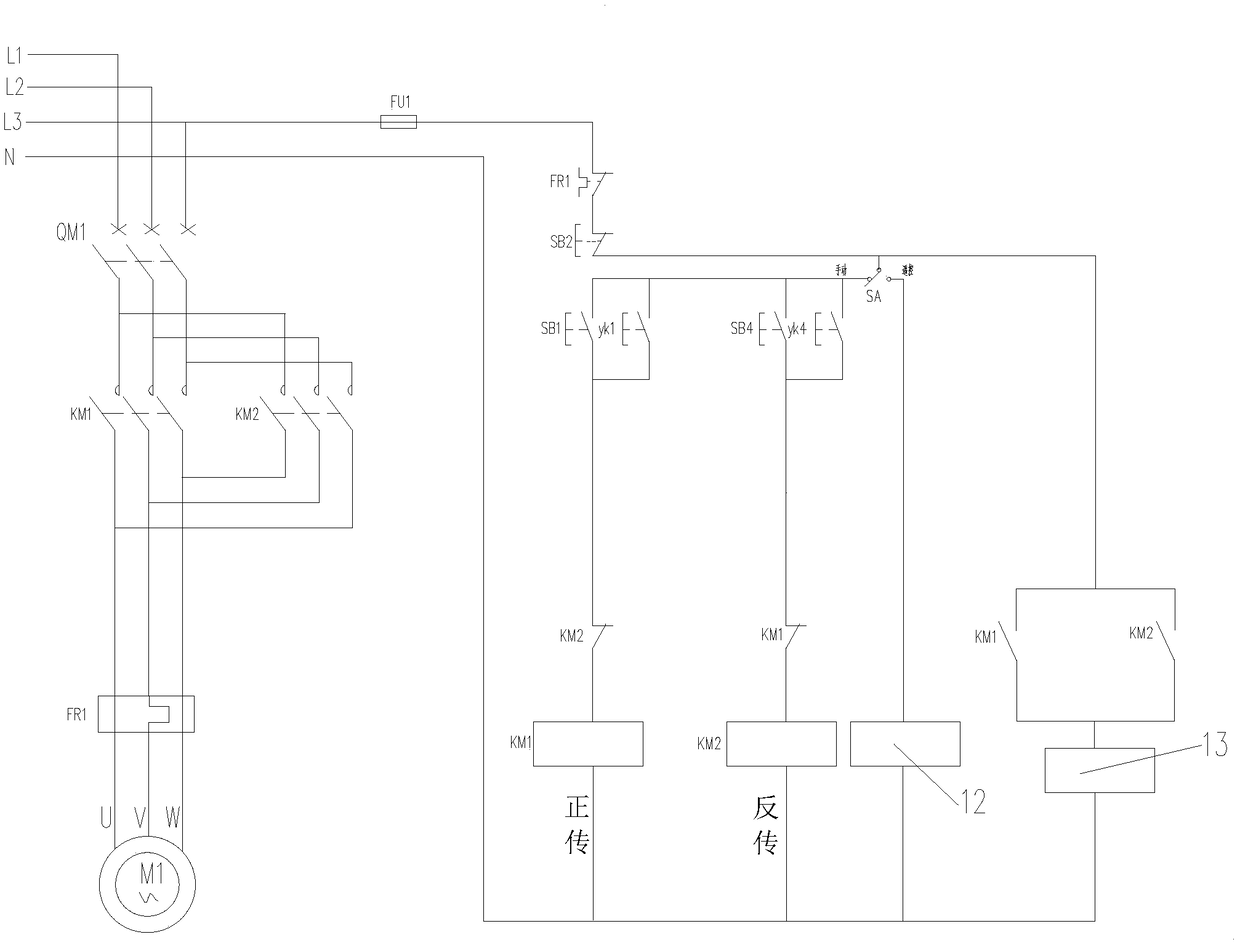

[0017] Such as Figure 1 to Figure 3 As shown, the control device for carrying and unloading the mixing furnace of the present invention includes a control box 10 and a hand-held wireless controller 20, the control box 10 is arranged on the frame of the mixing furnace, the hand-held wireless controller 20 and the control box 10 are connected to each other through wireless communication.

[0018] In this embodiment, the control box 10 includes at least a motor forward and reverse controller 11 and a wireless communicator 12, and the motor forward and reverse controller 11 and the wireless communicator 12 are connected to each other by communication; It communicates with the handheld wireless controller 20.

[0019] In this embodiment, the control box 10 is also provided with an audible and visual alarm 13 .

[0020] In this embodiment, the hand-held wireless controller 20 includes at least an operation controller 21 and a wireless communicator 22, and the operation controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com