Device and method for testing sleeve connecting structure grouting compactness in hammering pre-pressing mode

A connection structure and compactness technology, which is applied in the field of prefabricated building structure testing, can solve the problems of difficult quantitative detection of steel sleeve grouting compactness, and achieve the effects of reducing testing costs, improving quality, and accurate grouting compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and implementation steps.

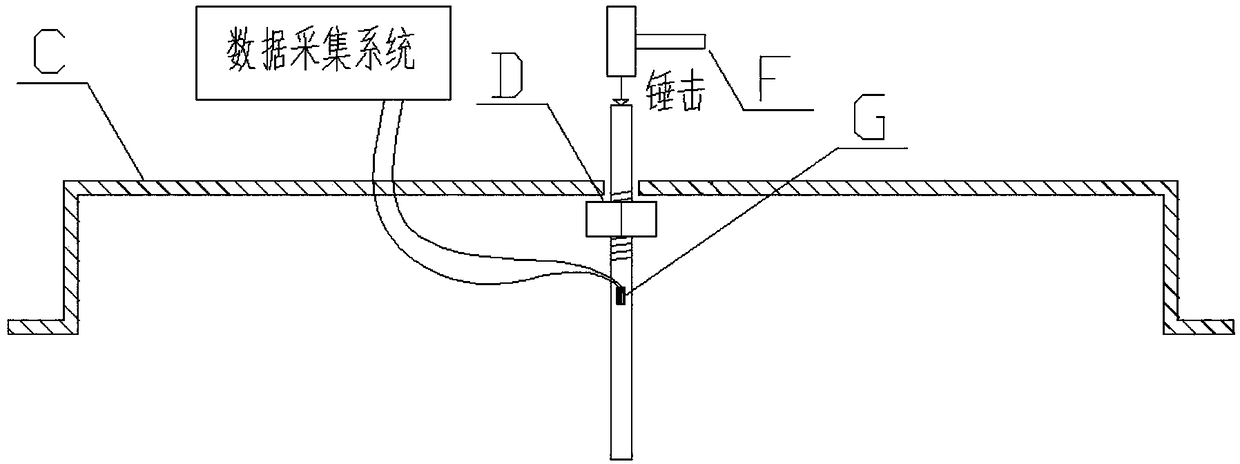

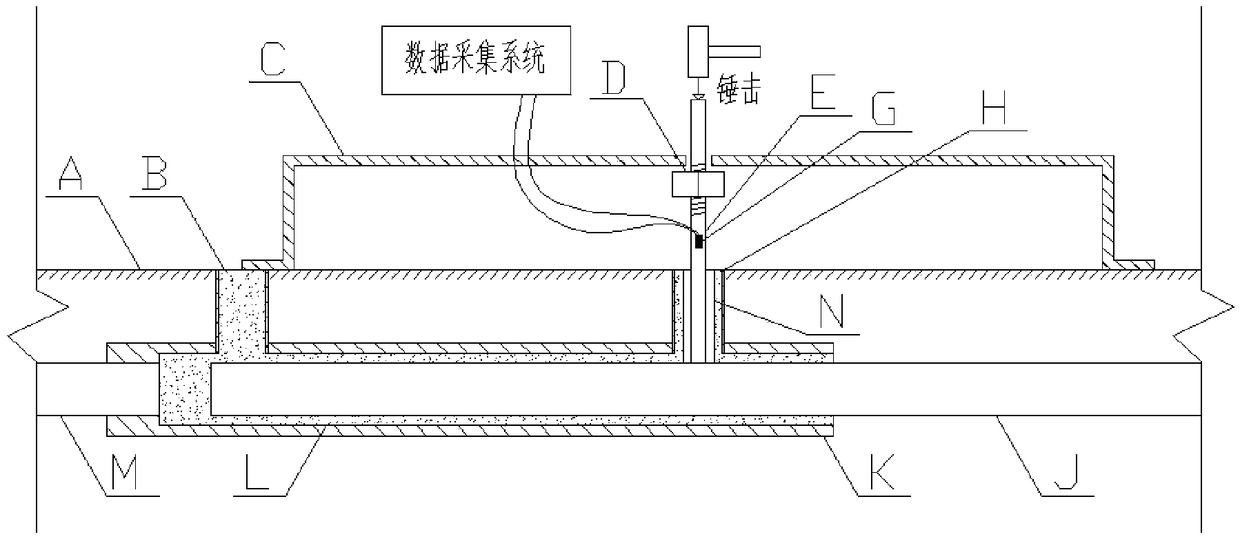

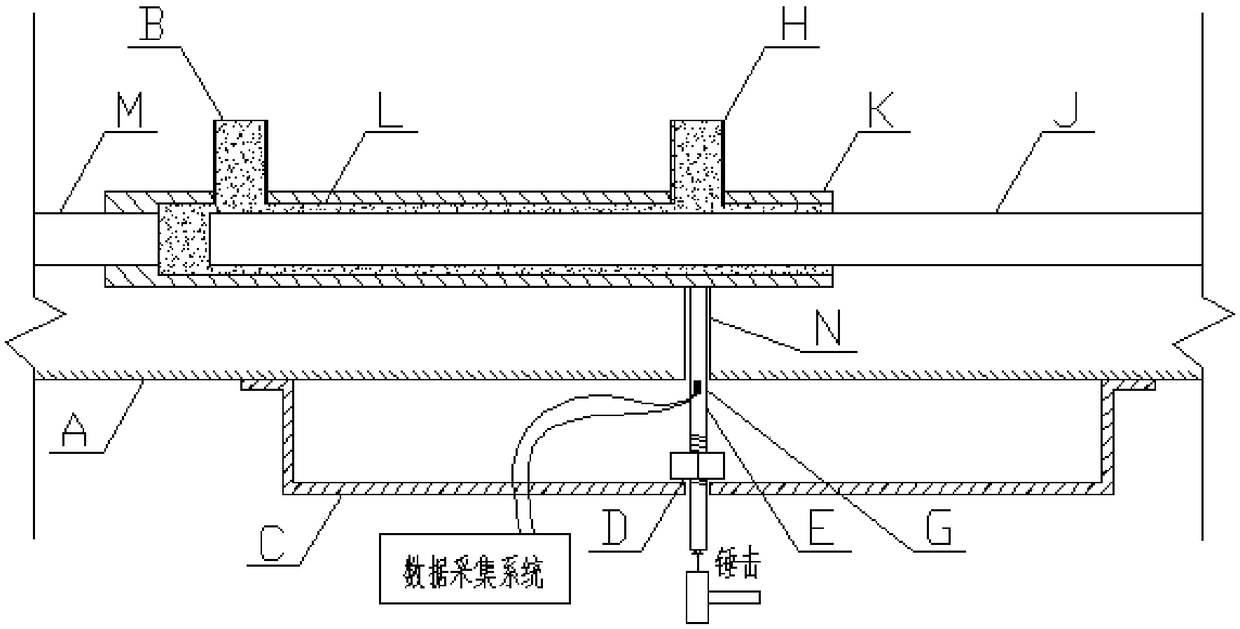

[0029] The present invention is suitable for detecting the grouting compactness of the sleeve connection structure. In the common sleeve connection structure, the first steel bar J and the second steel bar M are generally connected through the connecting sleeve, and the inner wall K of the sleeve is injected There is grouted concrete L. After the sleeve connection structure is grouted, there may be a problem of insufficient grouting density in the sleeve, so that the tensile bearing capacity is lower than the design value, which affects the safe and normal use of the sleeve connection structure. Therefore, in the present invention, the external steel structure preloading member C is installed in place, and a suitable preload is applied to the dowel F through the fixing nut D so that it is in direct or indirect close contact with the grouting co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com