Method for dispersing hydrogen internal combustion engine hydrogen jet flow and mixing gas

A hydrogen internal combustion engine and mixed gas technology, applied in internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of increasing residual hydrogen, reducing fuel utilization, hydrogen fuel loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and example the present invention will be further described:

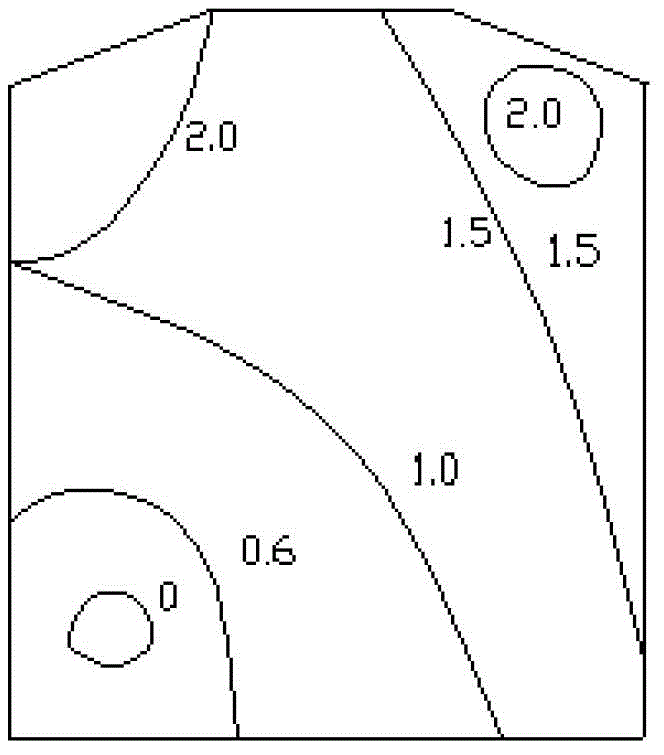

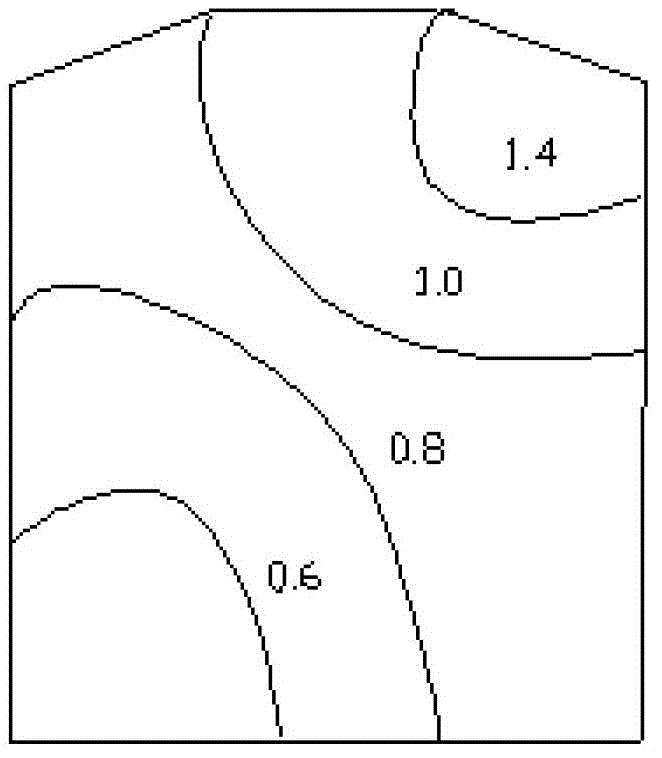

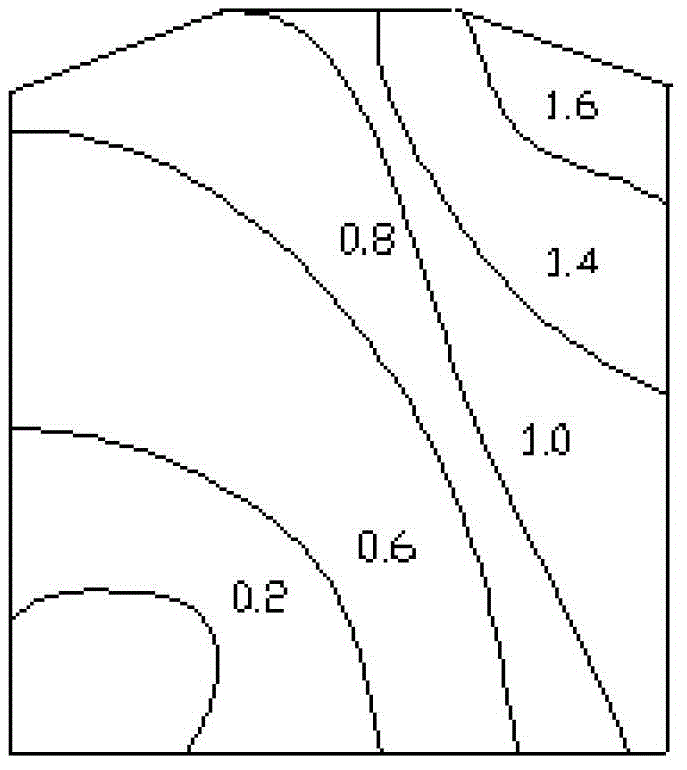

[0026] In this embodiment, a 4-cylinder PFI hydrogen internal combustion engine is selected, and its basic technical parameters are: displacement 2.0L, bore 87mm, stroke 86mm, connecting rod length 125mm, cylinder clearance height 1.3mm, compression ratio 10, intake air The inner diameter of the channel is 40mm, and the injection pressure of the hydrogen injection valve is 0.4MPa.

[0027] Firstly, determine the evaluation index of gas mixture uniformity. The present invention adopts the inhomogeneity coefficient n of the gas mixture in the cylinder index To evaluate the mixing uniformity of the mixture in the cylinder:

[0028] Divide the cylinder into finite volume units. When the unit is smaller than a certain scale, the gas mixture in each unit is considered to be completely uniform, and φ i Indicates the equivalent fuel-air ratio of unit i, V i Indicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com