Inertial impactor with wetted impaction surface to prevent particle loading effect

A technology of load effect and inertial impact, which is applied in the direction of instruments, scientific instruments, particle suspension analysis, etc., and can solve the problems of particle sampling or monitoring concentration underestimation, impactor interception diameter reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A number of implementations of the present invention will be described below with drawings and words. For the sake of clarity, many practical details will be described together in the following description. It should be understood, however, that these practical details should not be used to limit the invention. In addition, for the sake of simplifying the drawings, some existing structures and elements will be drawn in a simple and schematic way in the drawings.

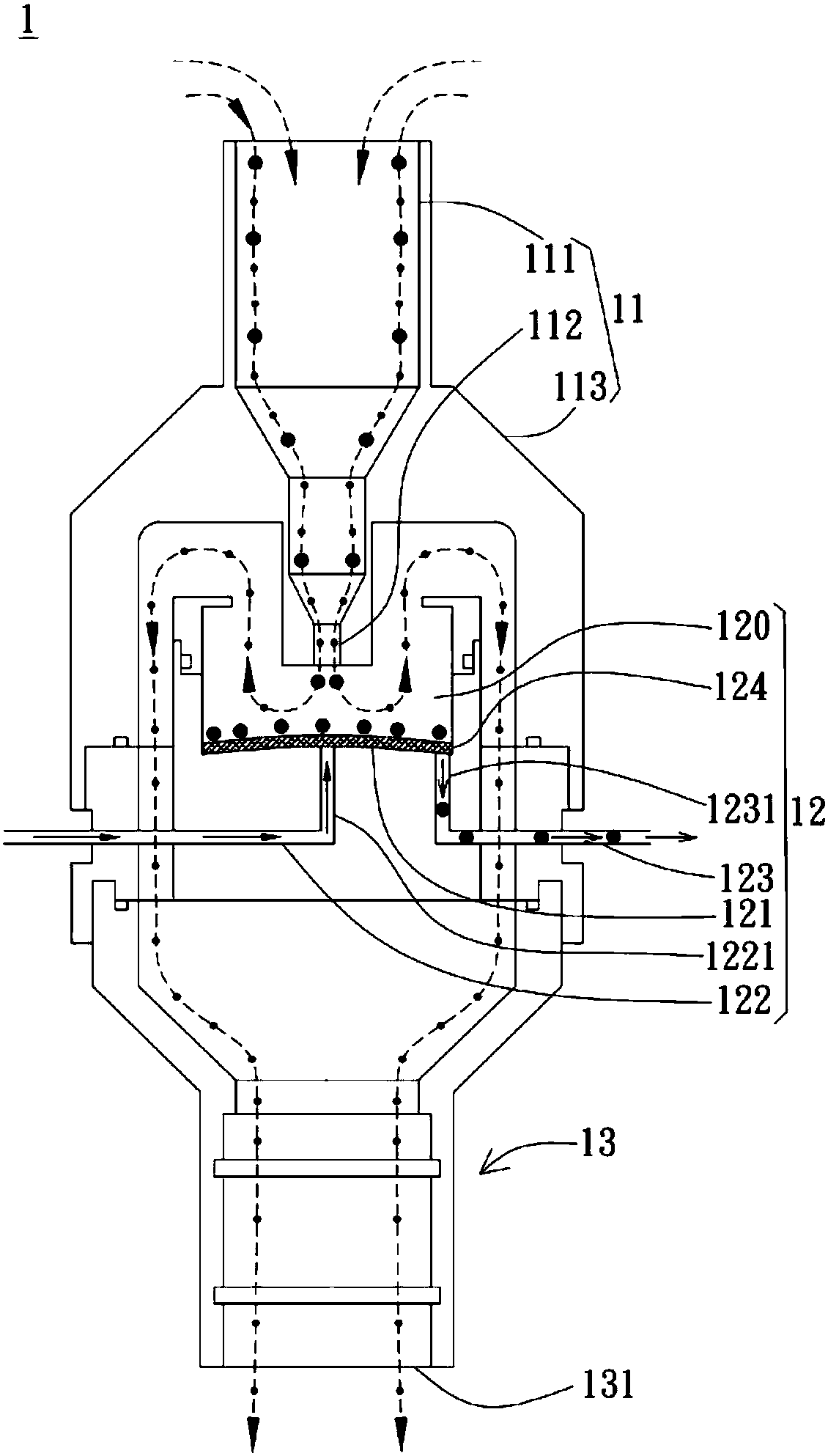

[0036] see figure 1 The particle impactor 1 includes an upper casing 11 , an impact portion 12 and a lower casing 13 connected to each other. The upper casing 11 preferably has a gas inlet 111 , a nozzle 112 connected to the gas inlet 111 , and an outer casing 113 extending downward from the upper casing 11 . The air inlet 111 is used to receive outside air. The impact part 12 is wrapped inside the outer casing 113 and has an impact well 120 , and the cavity surrounded by it corresponds to the nozzle 112 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com