A Method for Optimizing the Hobbing Process Parameters of CNC Gear Hobbing Machine

A technology of processing technology and optimization method, applied in the field of gear manufacturing, can solve problems such as less research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is further explained.

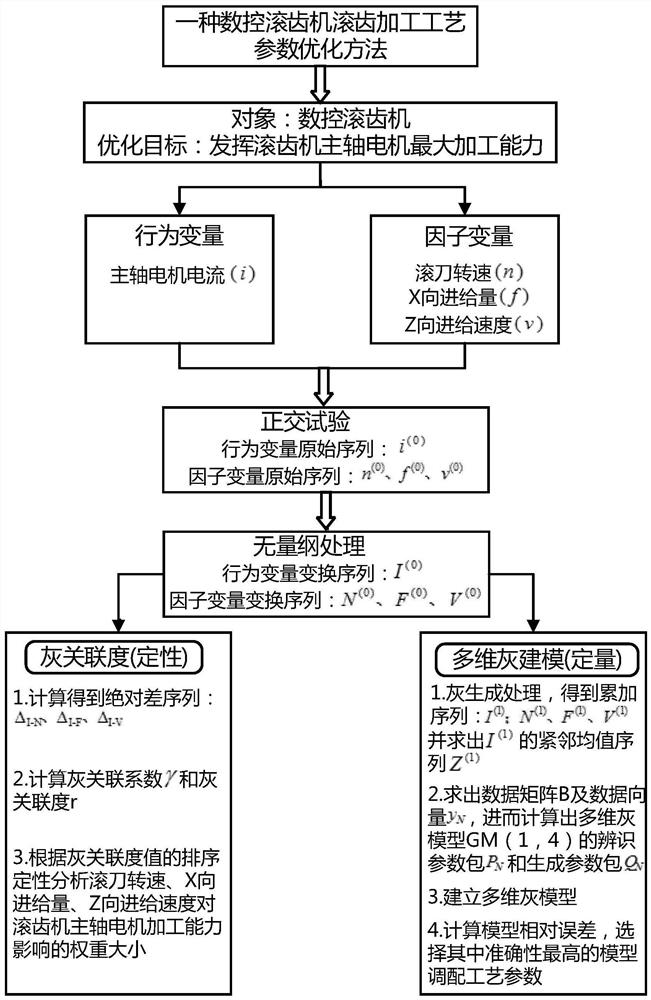

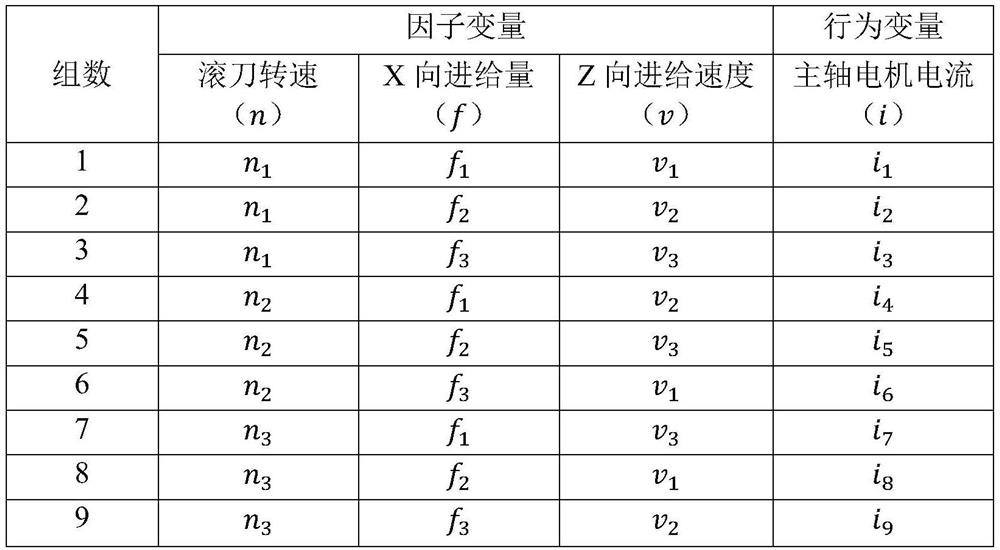

[0018] In this embodiment, the method for optimizing the hobbing process parameters of the CNC gear hobbing machine includes the following steps:

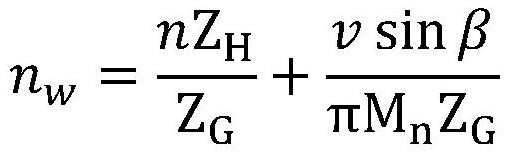

[0019] 1) Taking the maximum processing capability of the spindle motor of the hobbing machine as the optimization goal, the spindle motor current (i) is selected as the characteristic parameter of the processing capability of the spindle motor of the gear hobbing machine, that is, the behavioral variable; the spindle motor is the power output source of the feed system, and the motor is driven by current , so the magnitude of the spindle motor current can be used to characterize the capability of the motor. In addition, the current signal has the advantages of being easy to collect and not interfering with processing during the collection process, which is unmatched by other signals. Select hob speed (n), X-direction feed (f), Z-direction fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com