Ship coating training model

A kind of painting and ship technology, applied in the field of ship painting training model, can solve the problems such as difficult to implement teaching demonstration and group training, small and complicated hull space, etc., and achieve the effect of convenient teaching demonstration and group training, and simple model structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

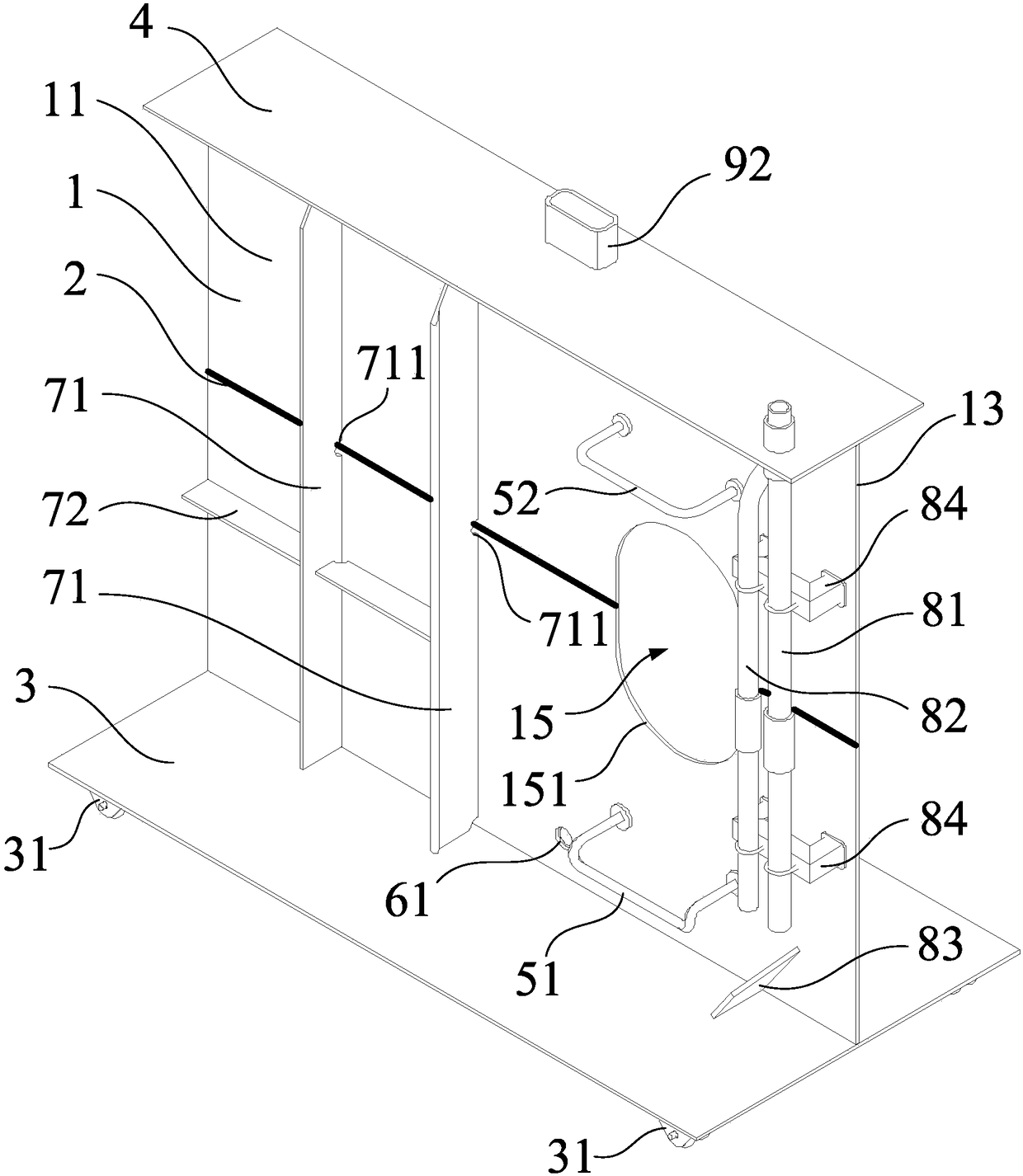

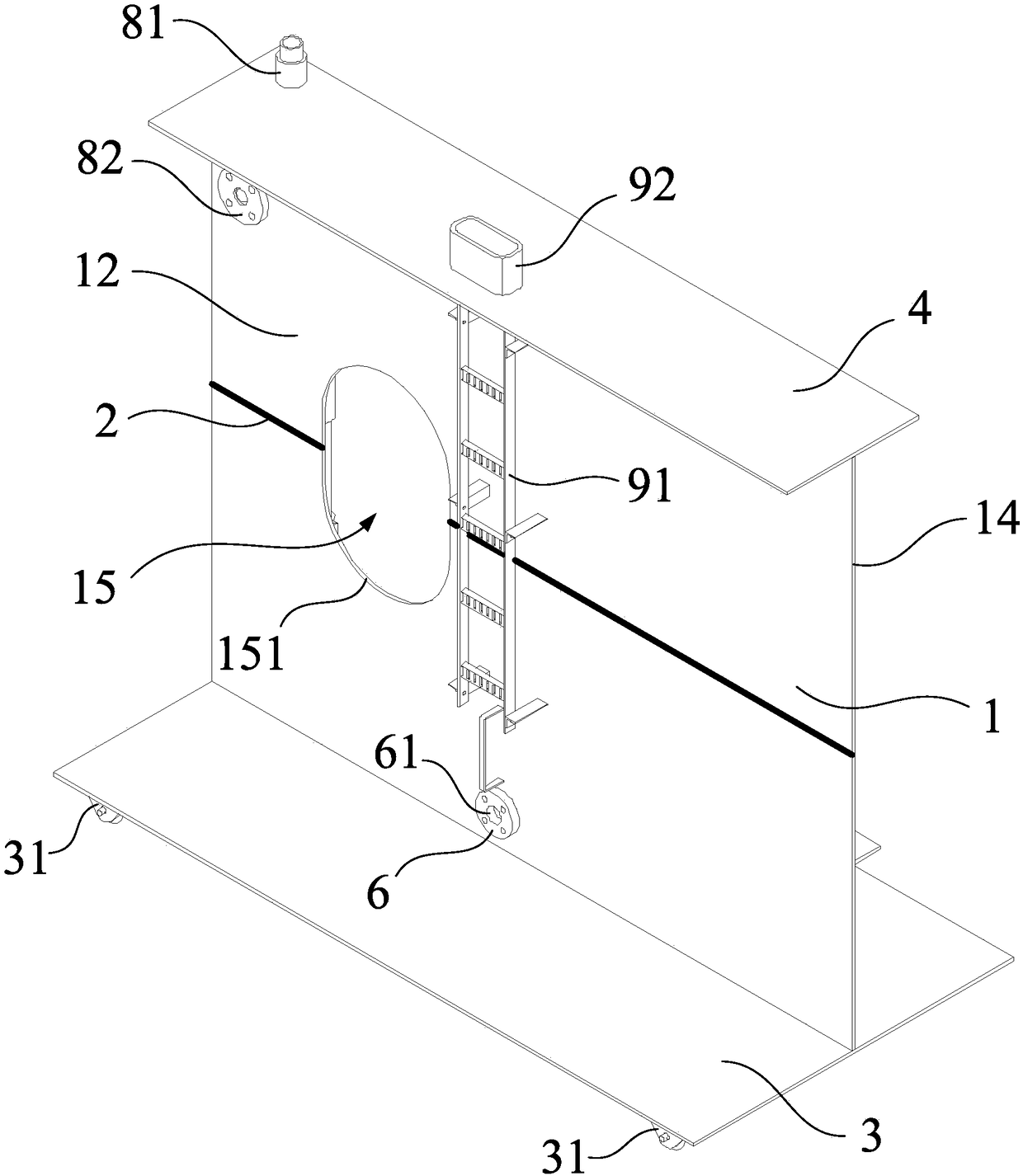

[0032] Such as figure 1 with figure 2 As shown, the ship painting training model includes a wall plate 1, a bottom plate 3 and a roof plate 4, all of which are made of steel plates. The wall panel 1 has a front surface 11 and a rear surface 12 oppositely arranged and a first side (not shown in the figure), a second side 13, a third side (not shown in the figure) and a fourth side connected end to end in sequence 14 , these four sides are all adjacent to the front surface 11 and the rear surface 12 of the wall panel 1 . Wherein, the first side (not shown in the figure) is located at the bottom of the wall plate 1, and is welded to the surface of the bottom plate 3; the third side (not shown in the figure) is located at the top of the wall plate 1, and is welded to the surface of the top plate 4 . The wall board 1 is perpen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com