Furnace top information collecting system of blast furnace based on field bus and information collecting method thereof

A field bus and information collection technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of low accuracy of signal collection, complicated production conditions, complicated collection process, etc., and improve the time for emergency repair , Avoid cable laying, save hardware investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

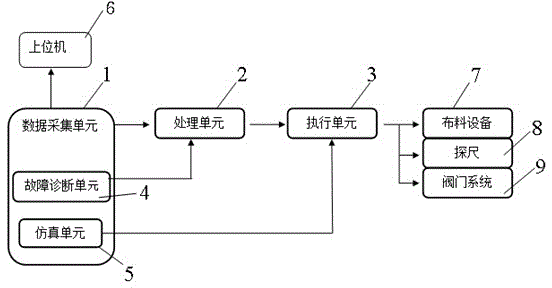

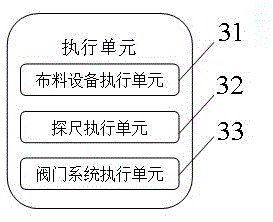

[0042] The execution unit 3 includes a distribution equipment execution unit 31, a probe execution unit 32 and a valve system execution unit 33. The output end of the distribution equipment execution unit 31 is connected to the distribution equipment 7 of the blast furnace top equipment. The output end of the probe execution unit 32 is connected with the probe 8 of the blast furnace top equipment, and the output end of the valve system execution unit 33 is connected with the valve system 9 of the blast furnace top equipment.

[0043] The field bus in the data acquisition unit 1 also includes a fault diagnosis unit 4 and a simulation unit 5, the output terminal of the fault diagnosis unit 4 is connected to the processing unit 2, and the fault diagnosis unit 4 adopts the bus diagnosis provided by the field module of the field bus function, that is, the realization of the diagnosis function of the Turck field module. The output terminal of the simulation unit 5 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com