Backlight module and display device with same

A technology of backlight module and fluorescent film, applied in the field of backlight module and display device, can solve the problems of hollow gap change, loose diaphragm, unfavorable cost, etc., to increase transmittance, reduce the number of layers, and increase the light mixing distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following description of the embodiments refers to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced. The directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "top", "bottom", etc., are only for reference to the attached drawings. direction. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention.

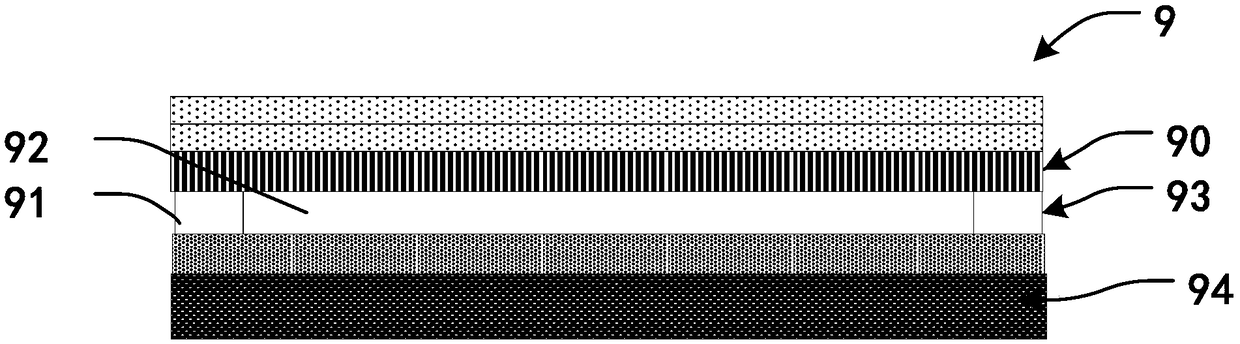

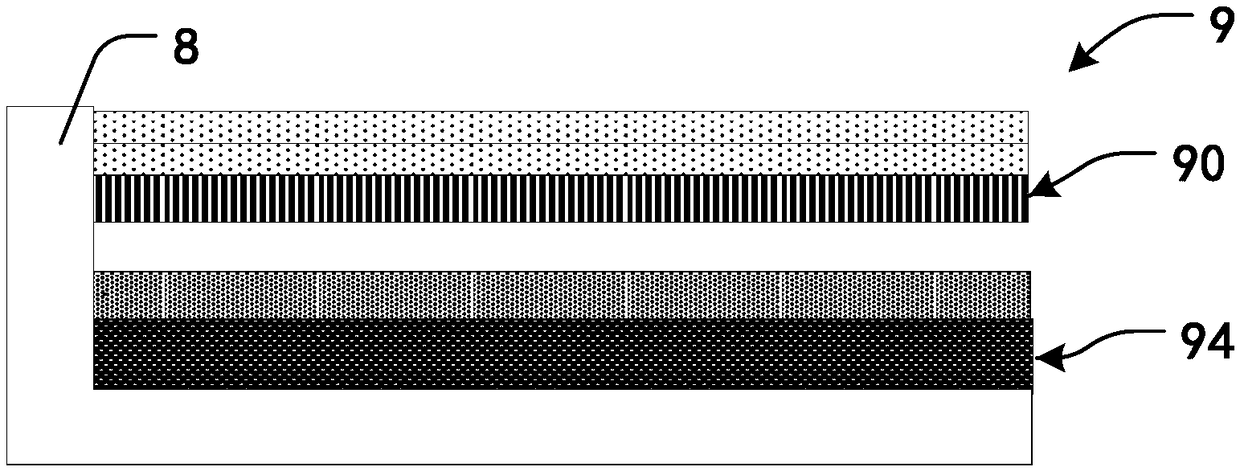

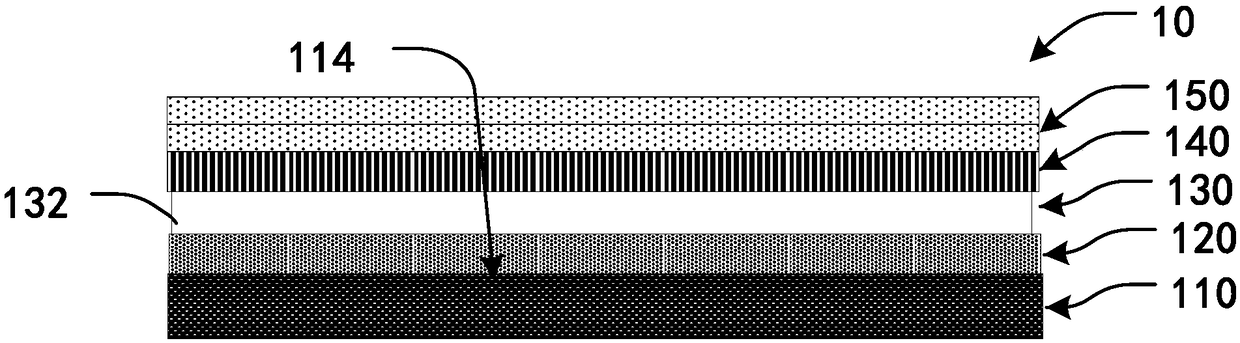

[0040] Such as image 3 As shown, in one embodiment, the backlight module 10 of the present invention includes a surface light source 110 , a fluorescent film 120 , a supporting layer 130 , a diffusion sheet 140 and a prism sheet 150 .

[0041] Such as Figure 4 As shown, the surface light source 110 has a light emitting surface 114 . In this embodiment, the surface light source 110 includes a substrate 111 , several chips 112 and a reflective layer 113 . One of the surfaces of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com