Heat dissipation plate and manufacturing method thereof

A manufacturing method and technology for a heat dissipation plate, which are applied in cooling/ventilation/heating transformation, electrical equipment structural parts, instruments, etc., can solve the problems of complex heat pipe structure, increased manufacturing cost of electronic products, and unfavorable thin design of electronic products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

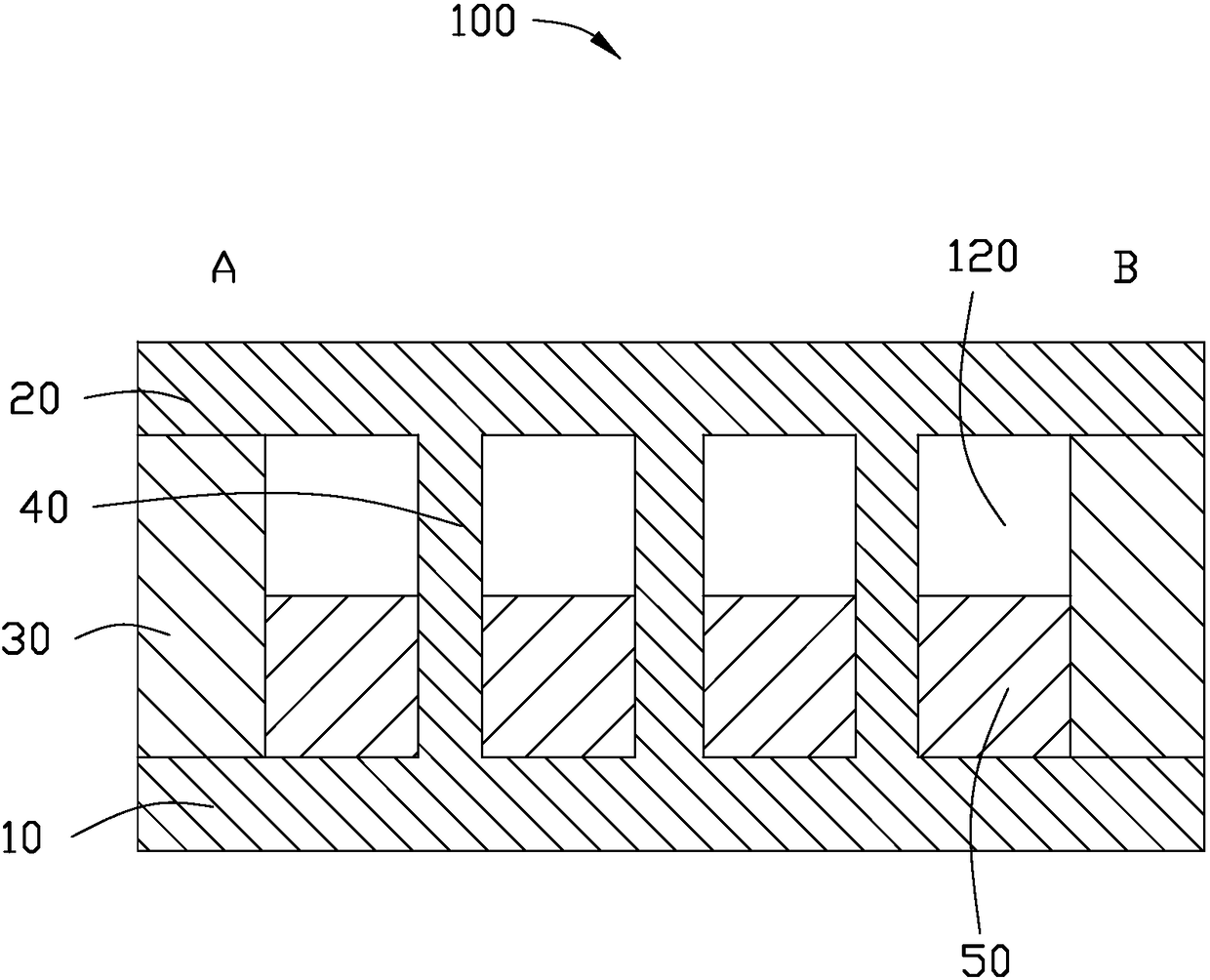

[0038] like figure 1 As shown, in the embodiment of the present invention, the heat dissipation plate 100 is used for dissipating heat in an electronic product.

[0039] The heat dissipation plate 100 includes a first plate body 10 , a second plate body 20 disposed opposite to the first plate body 10 , a fixing adhesive layer 30 connecting the first plate body 10 and the second plate body 20 , a support column 40 , and the cooling liquid 50 accommodated between the first plate body 10 and the first plate body 10 .

[0040] The heat dissipation plate 100 has a first end A and a second end B. The first section A is an evaporation section, and the second end B is a condensation section.

[0041] Understandably, the first section A is the condensation end, and the second end B is the evaporation end. The first end A and the second end B are located at two ends of the first plate body 10 respectively.

[0042] In the heat dissipation plate 100 according to the first embodiment ...

no. 2 example

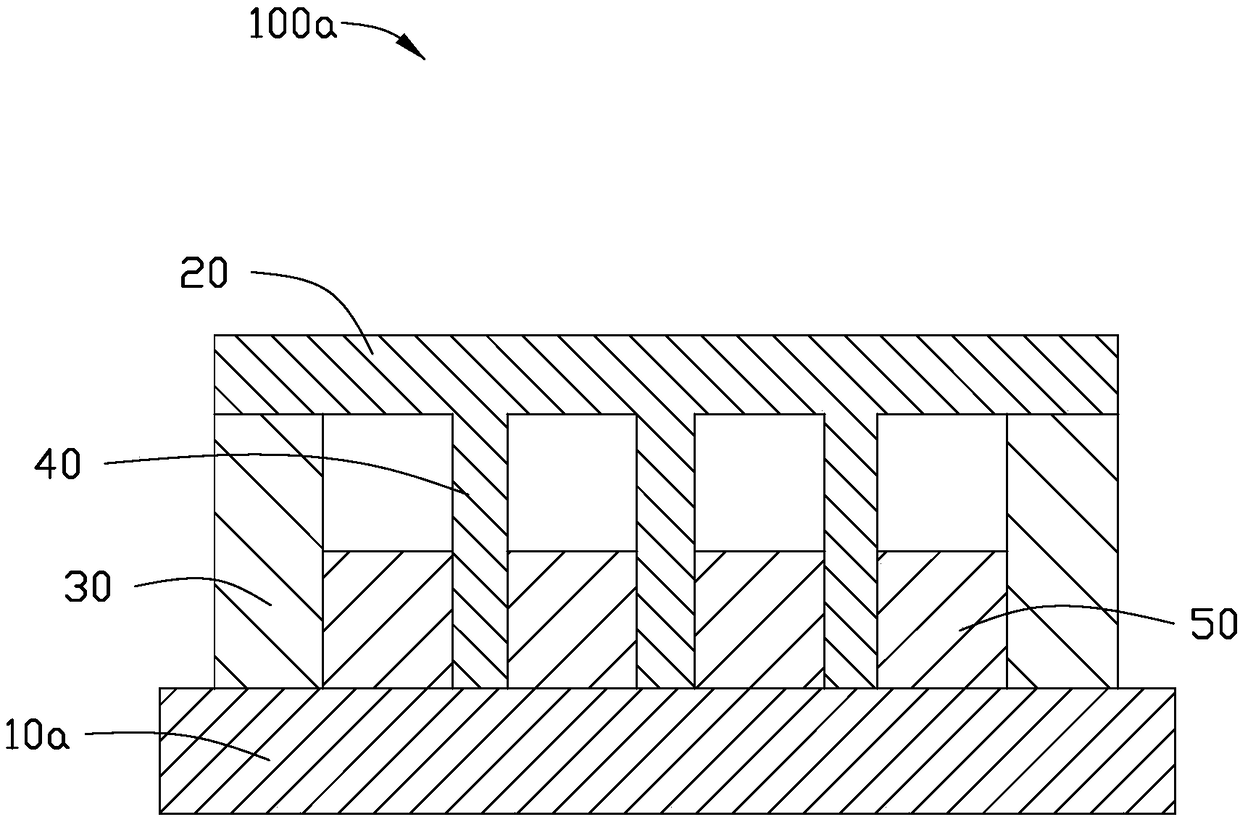

[0053] like figure 2 As shown, the heat dissipation plate 100a of the second embodiment of the present invention is similar to the heat dissipation plate 100 of the first embodiment, and the difference is that the first plate body 10a is an electronic product support structure.

no. 3 example

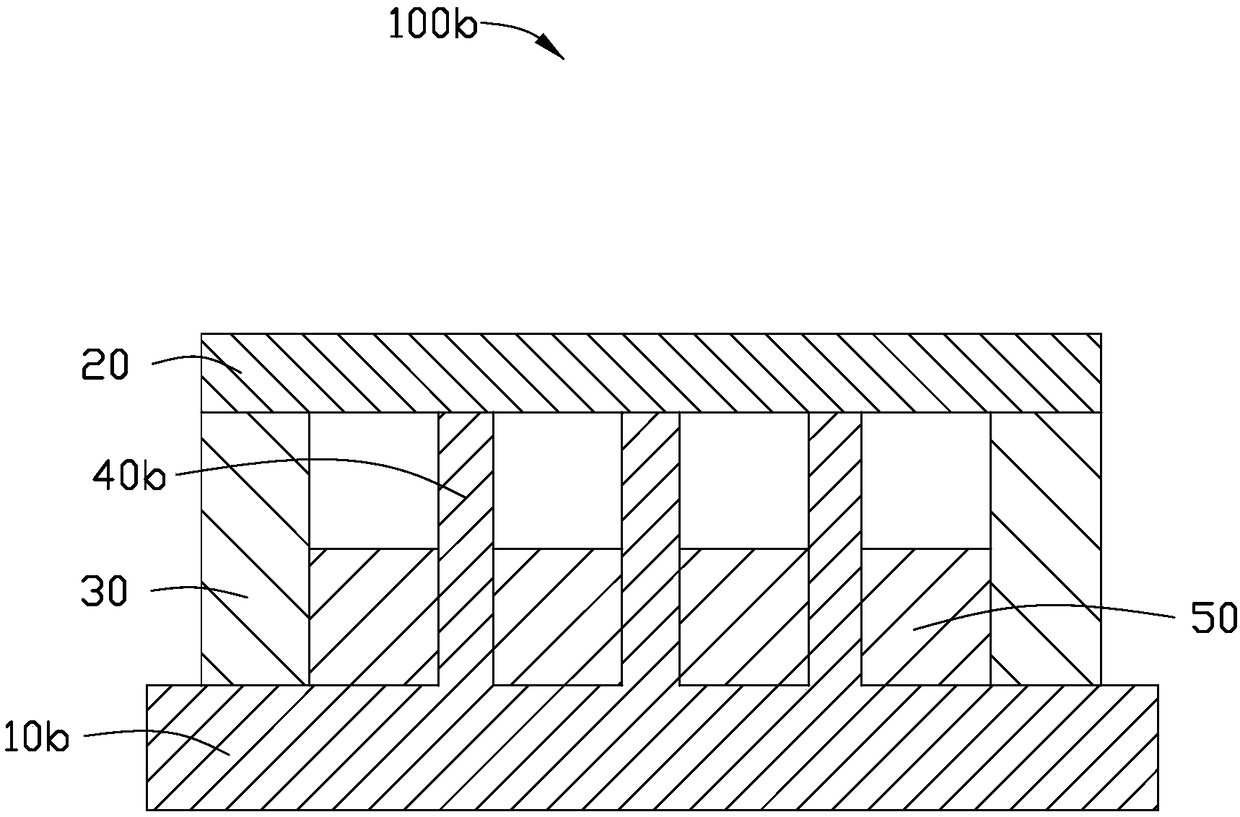

[0055] like image 3As shown, the heat dissipation plate 100b of the third embodiment of the present invention is similar to the heat dissipation plate 100 of the first embodiment, and the difference lies in that: the first plate body 10b is a supporting structure for electronic products, and the support columns 40b are Electronic product support structure. The support column 40b and the first plate body 10b are separately formed or integrally formed. The support column 40b extends vertically from the first plate body 10b toward the first plate body 10b and is connected to the second plate body 20 .

[0056] like Figure 4 As shown, when the heat dissipation plate of the present invention works, the first end A of the heat dissipation plate is in contact with a heat source 200 . The cold cooling liquid 50 is evaporated at the first end A, and the evaporated gas of the cooling liquid 50 flows back to the second end B along the inner wall of the first plate body 10 after bein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com