Valve for closing and opening a line system

A technology for piping systems, closing elements, applied in the direction of devices used to relieve pressure on sealing surfaces, valve details, valve devices, etc., can solve problems such as increased current consumption, negative effects of fuel consumption, reduced effective distance, etc., Achieving the effect of low additional cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

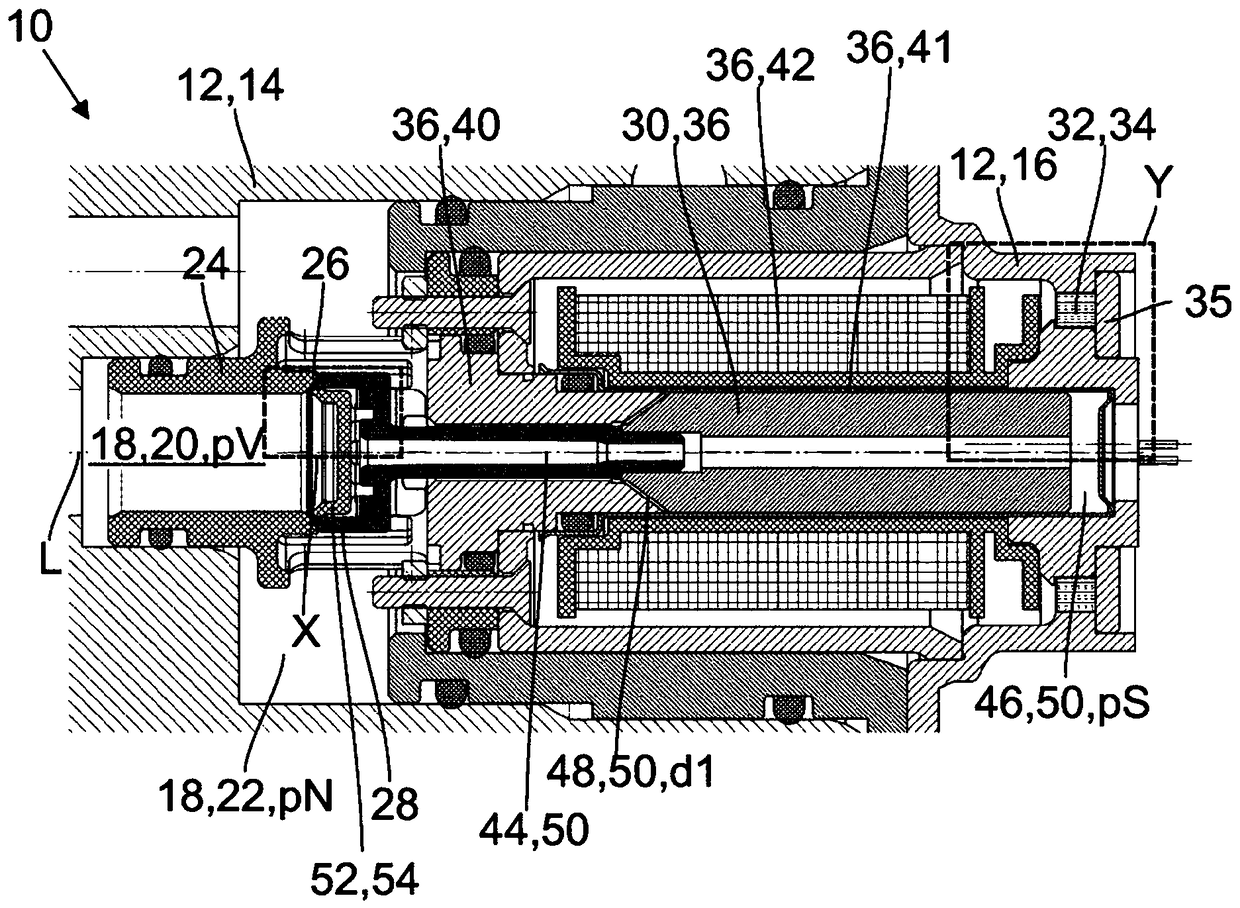

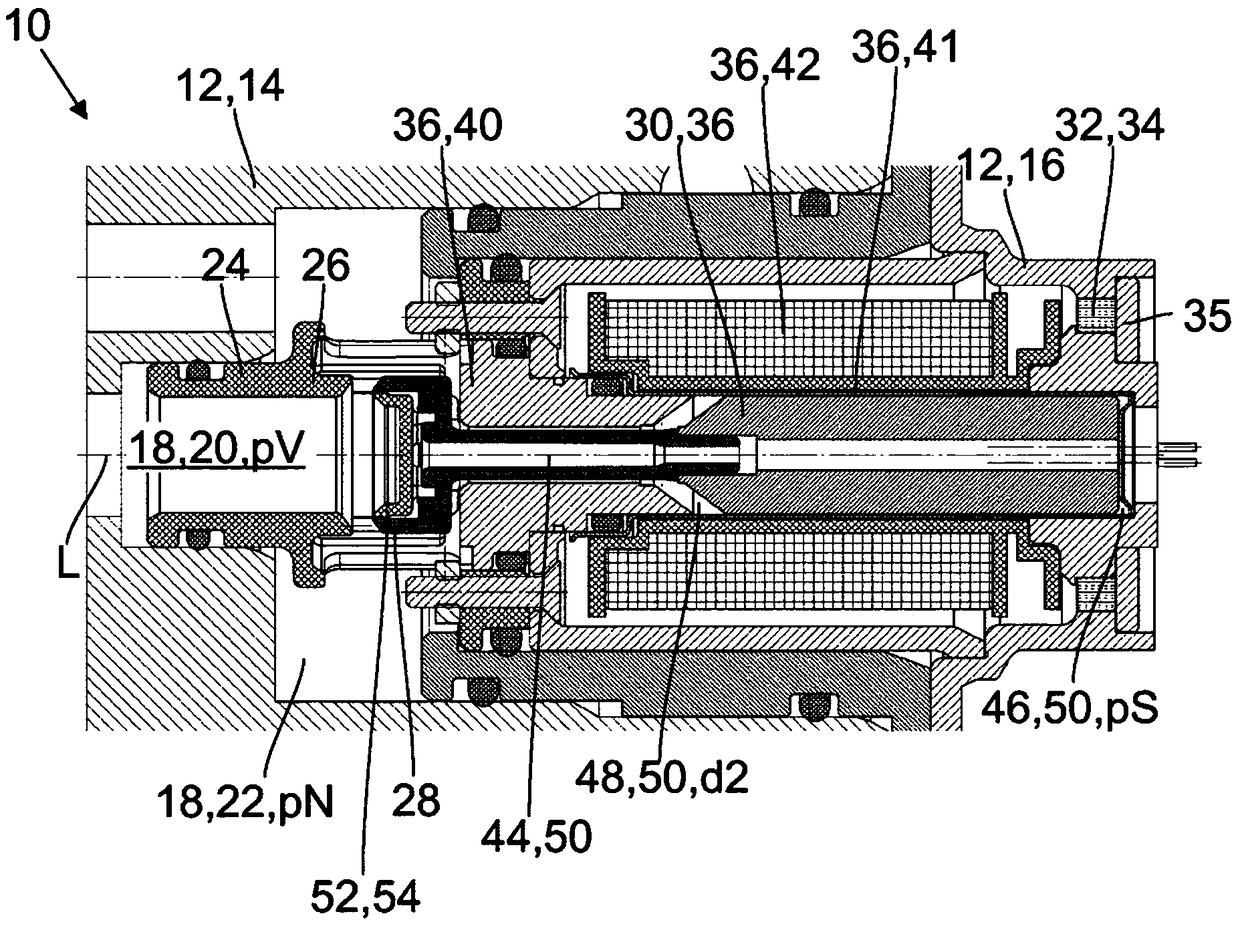

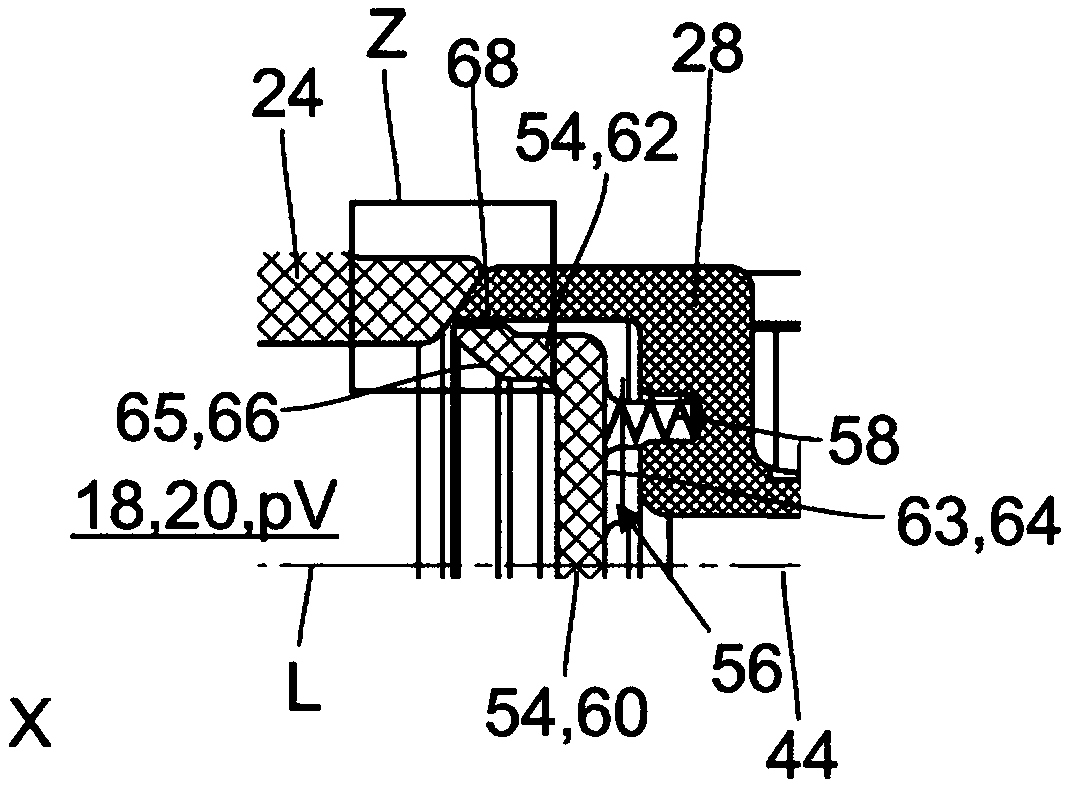

[0042] exist figure 1 An embodiment of a fluid control valve 10 according to the invention is shown in cross-section in FIG. The valve 10 has a housing 12 with a first housing part 14 and a second housing part 16, wherein a line system 18 is arranged in the first housing part 14, the line system 18 comprising an inlet line 20 and outlet pipeline 22. Furthermore, a valve body 24 which forms a valve seat 26 is arranged in the first housing part 14 . The valve body 24 can be made of metal or plastic, for example. Furthermore, the valve 10 comprises a closing element 28 which is arranged movably along the longitudinal axis L. As shown in FIG. The closing element 28 is connected to an armature 30 which cooperates with a reset element 32 , in this case with a radially magnetized permanent magnet 34 . The permanent magnet 34 is arranged in a correspondingly designed receptacle of the second housing part 16 and is fixed in this receptacle by means of a non-magnetic plate-shaped bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com