Composite material for producing an acoustic membrane

A composite material, acoustic technology, applied in the direction of polymer material diaphragm, application, electronic equipment, etc., can solve the problems of high shear force, thermoforming is not preferred, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

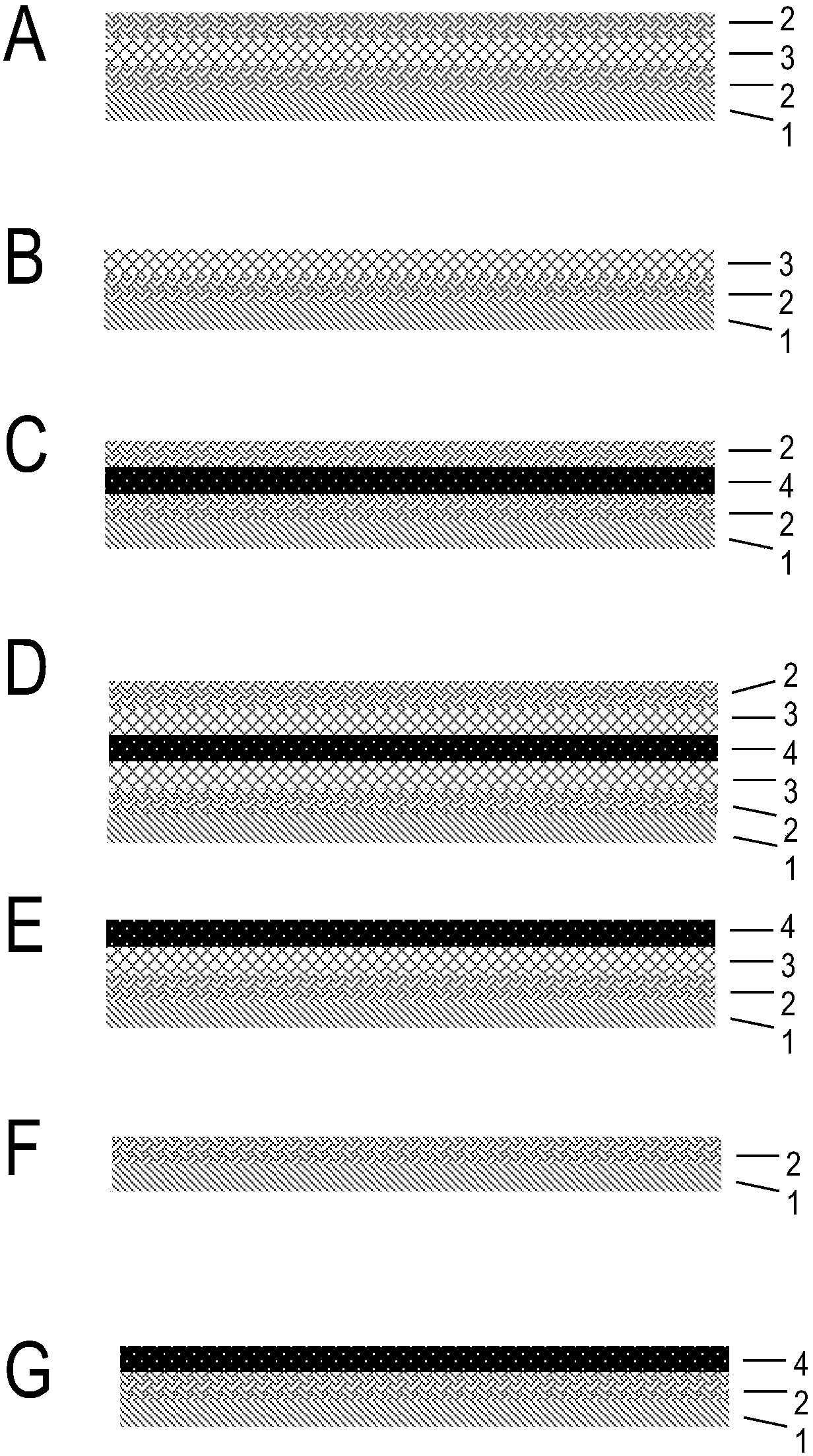

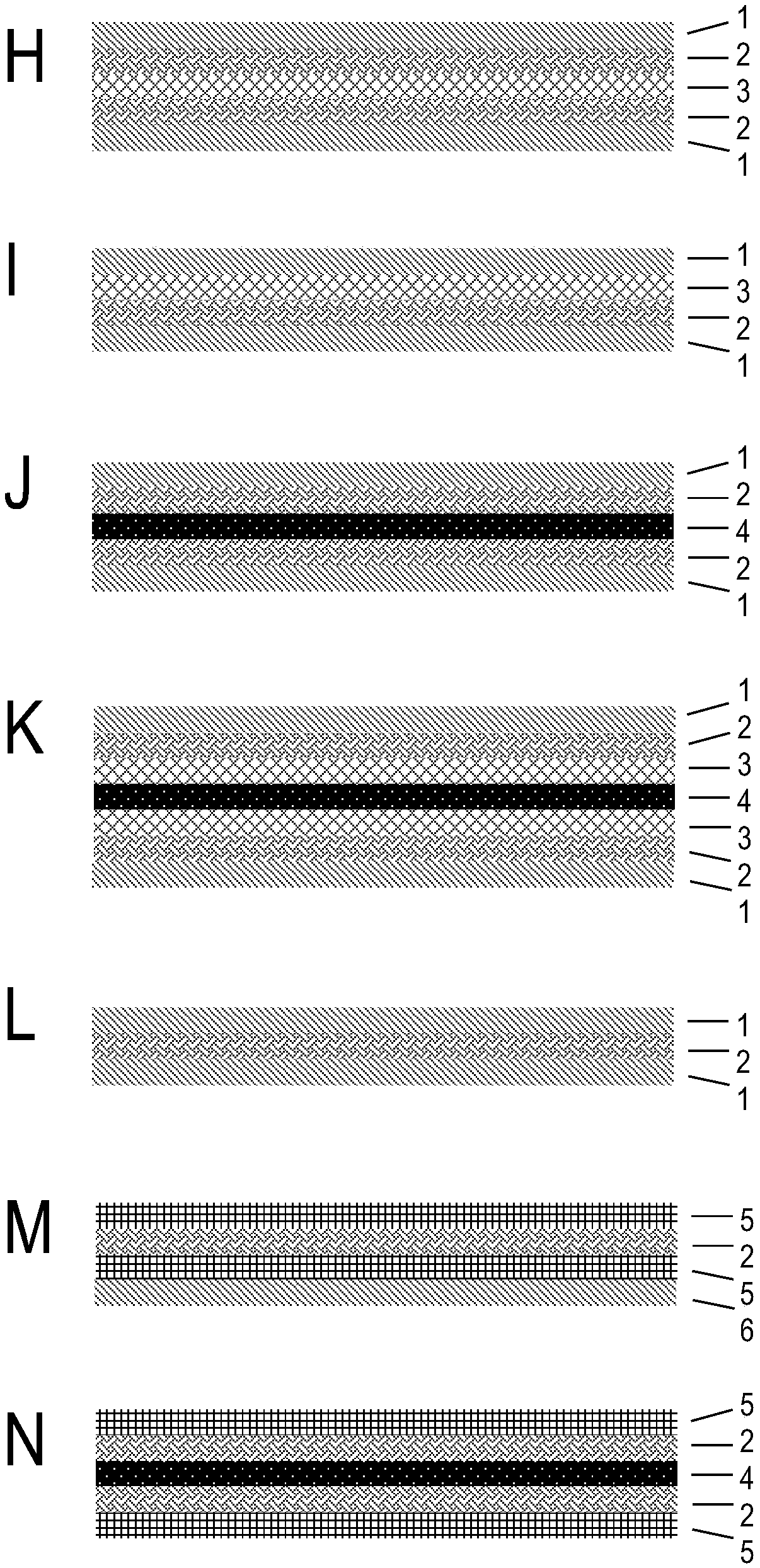

[0081] Different configurations of composite materials according to the invention

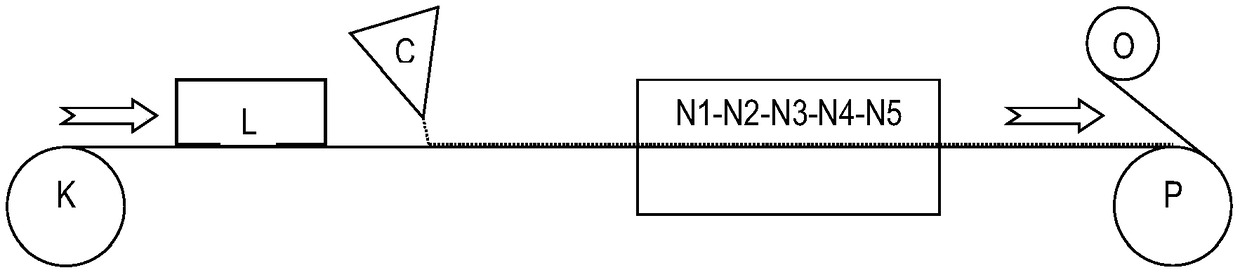

[0082] figure 1 A to N show different configurations of the composite material according to the invention with at least one support layer 1 or 5 and a polysiloxane layer 2 . They can be composed, for example, as follows:

[0083] exist figure 1 In preferred configurations A to L, the support layer is the bottom outer layer of the configuration. Words such as "top" and "bottom" are not intended to denote a certain orientation of the film, but are merely used to describe the drawings diagrammatically. Here, the support layer is the release layer 1 and said release layer 1 can be removed from the composite material. exist figure 1 In configurations H to L, the top outer layer also acts as a support layer for release layer 1. Preferred materials for the release layer labeled 1 are, for example, PET films with a single-sided siliconized surface, PET films with a symmetrical siliconized surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com