Polytetrafluoroethylene spun-fiber waterproof acoustic-transmission membrane and production method thereof

A PTFE spinning, waterproof sound-permeable membrane technology, applied in the direction of membrane structure, textile and papermaking, non-planar diaphragm/paper cone, etc. performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

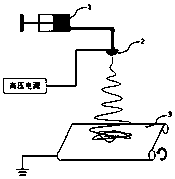

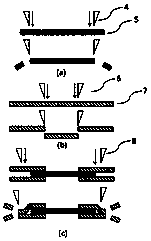

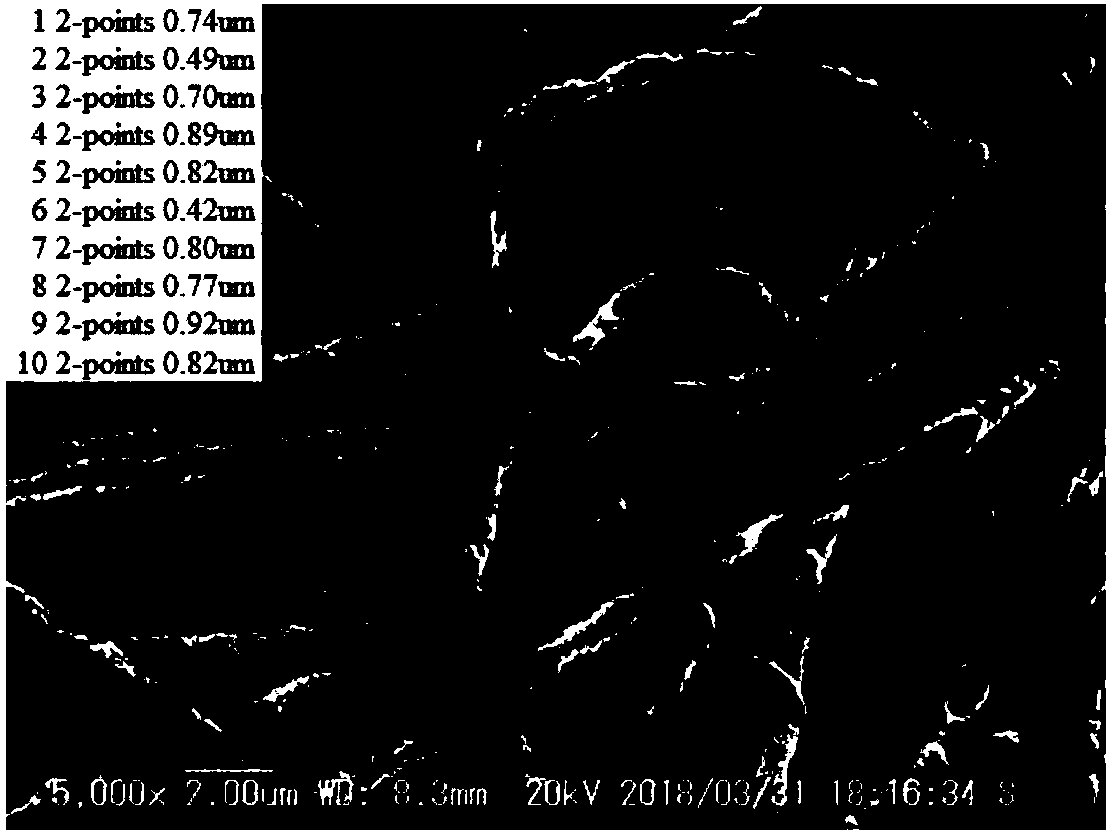

[0030] (1) Preparation of PTFE spinning fiber membrane 5

[0031] a. Nanoparticle suspension of polytetrafluoroethylene PTFE with an average particle diameter of 230 nm and a mass fraction of 50% and an aqueous solution of polyoxyethylene PEO with a mass fraction of 1% and an average molecular weight of 100,000 g / mol at a ratio of 1:30 The mass ratio was mixed, and heated and stirred at 20 ° C for 5 h to obtain a uniformly mixed slurry 1;

[0032] b. Remove the air bubbles in the mixed slurry 1 in an ultrasonic water bath at 20 °C and 20 kHz for 60 min;

[0033] c. Put the slurry 1 that has been stirred and treated in an ultrasonic water bath into the syringe barrel. The distance between the silk plates is 10 cm, and the speed of 10 cm / min moves back and forth between the horizontal distance of 5 cm; while the spinneret 2 moves back and forth horizontally, the slurry 1 is ejected at the speed of 0.1 ml / h, and the ejected slurry Material 1 is spun into polytetrafluoroethylene...

Embodiment 2

[0044] (1) Preparation of PTFE spinning fiber membrane 5

[0045]a. The nanoparticle suspension of polytetrafluoroethylene PTFE with an average particle diameter of 230 nm and a mass fraction of 65% and an aqueous solution of polyoxyethylene PEO with a mass fraction of 10% and an average molecular weight of 1,000,000 g / mol are 1:150 The mass ratio was mixed, and heated and stirred at 35 ° C for 3 h to obtain a uniformly mixed slurry 1;

[0046] b. Remove the air bubbles in the slurry 1 in an ultrasonic water bath at 35 °C and 30 kHz for 30 min;

[0047] c. Add the slurry 1 that has been stirred and treated in an ultrasonic water bath into the syringe barrel. The distance between the silk plates is 30 cm, and the horizontal distance of 30 cm is moved back and forth at a speed of 30 cm / min; while the spinneret 2 is moving back and forth horizontally, the slurry 1 is ejected at a speed of 5 ml / h, and the ejected Slurry 1 is spun into polytetrafluoroethylene fiber filaments unde...

Embodiment 3

[0058] (1) Preparation of PTFE spinning fiber membrane 5

[0059] a. The nanoparticle suspension of polytetrafluoroethylene PTFE with an average particle diameter of 230 nm and a mass fraction of 80% and an aqueous solution of polyoxyethylene PEO with a mass fraction of 20% and an average molecular weight of 100,000,000 g / mol at a ratio of 1:300 The mass ratio was mixed, and heated and stirred at 50 ° C for 5 h to obtain a uniformly mixed slurry 1;

[0060] b. Remove the air bubbles in the mixed slurry in an ultrasonic water bath at 50 °C and 40 kHz for 60 min;

[0061] c. Put the slurry 1 that has been stirred and treated in an ultrasonic water bath into the syringe barrel. The distance between the silk plates is 40 cm, and it moves back and forth between the horizontal distance of 50 cm at a speed of 50 cm / min; the spinneret 2 ejects the slurry 1 at a speed of 10 ml / h while moving back and forth horizontally, and the ejected Slurry 1 is spun into polytetrafluoroethylene fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com