Porous seamless capsule dripper

A technology of seamless capsule and dripper, which is used in capsule delivery, drug delivery, household components, etc., can solve the problems of large floor space, restricting the industrial production of seamless capsules, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

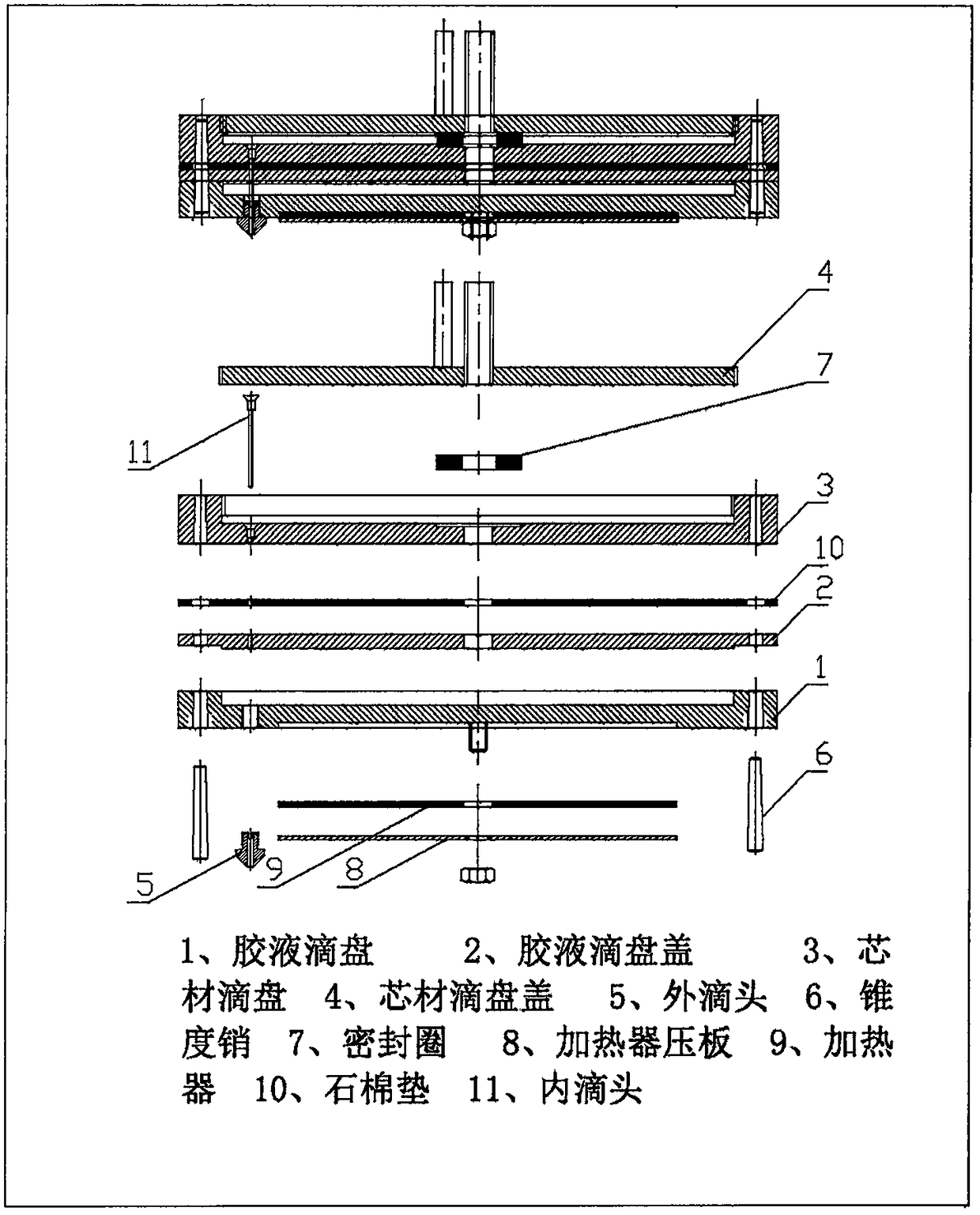

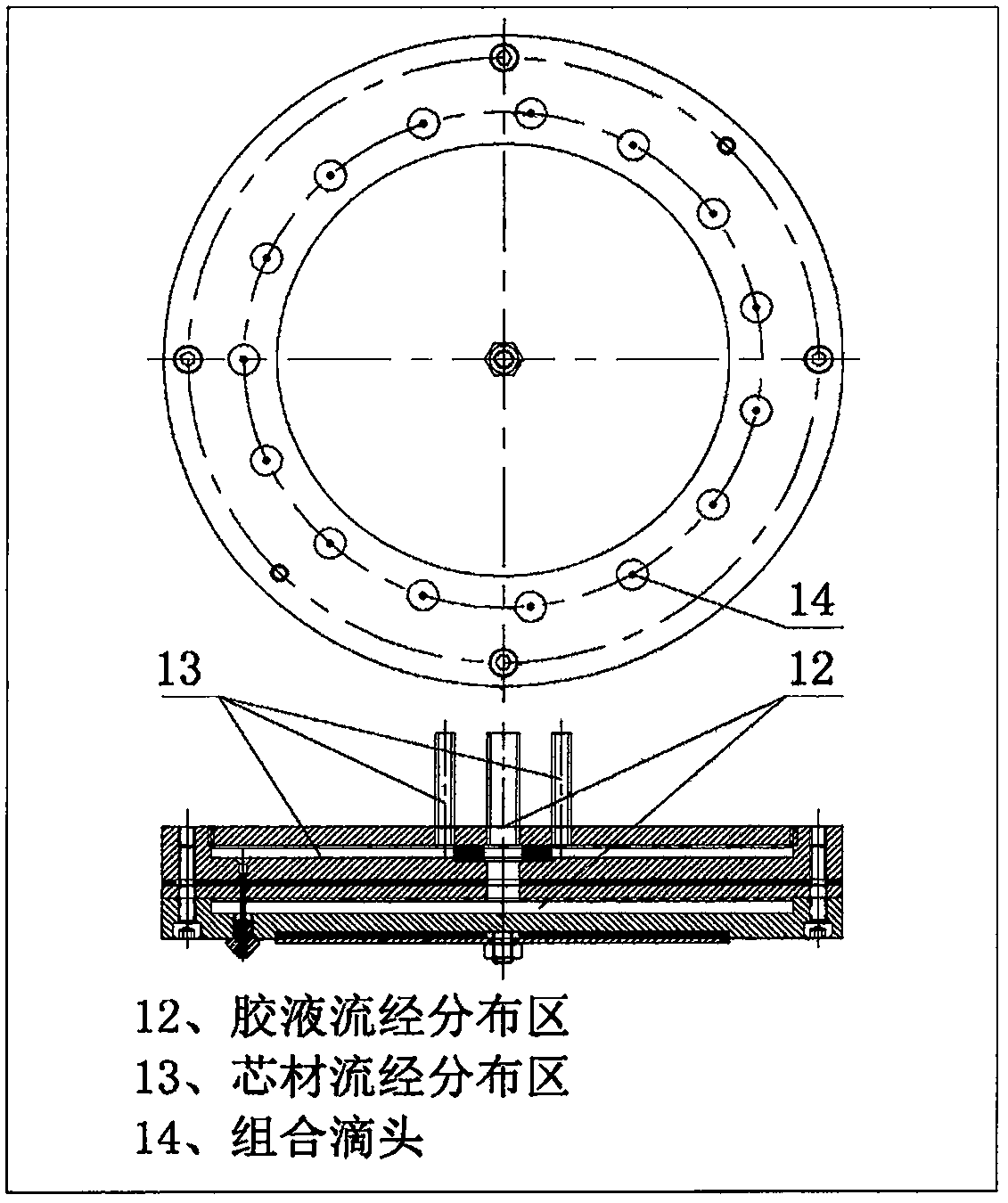

[0008] The porous seamless capsule dripper is mainly composed of the glue dripping tray 1, the glue dripping tray cover 2 and the outer dripping head 5 to form the glue dripping part, and the heater 9 installed at the bottom is the glue dripping tray 1 and the glue dripping tray. The cover 2 and the outer dripper 5 are insulated. The core material drip tray 3, the core material drip tray cover 4 and the inner dripper 11 are assembled into a core material dripping part. Asbestos pad 10 is installed between two groups of drip pans to avoid the heat conduction of the seamless capsule drip pan to the core material drip pan. Position and assemble the glue dripping part, asbestos pad and core material dripping part through the taper pin 6, so that the outer dripper and the inner dripper of each set of seamless capsules are combined in concentric circles, and the glue flows through the distribution area 12 through the glue Evenly transported to each outer dripper, the core material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com