Exhaust gas emission and treatment equipment

A treatment equipment and waste gas emission technology, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separating agents. Issues such as limited contact surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

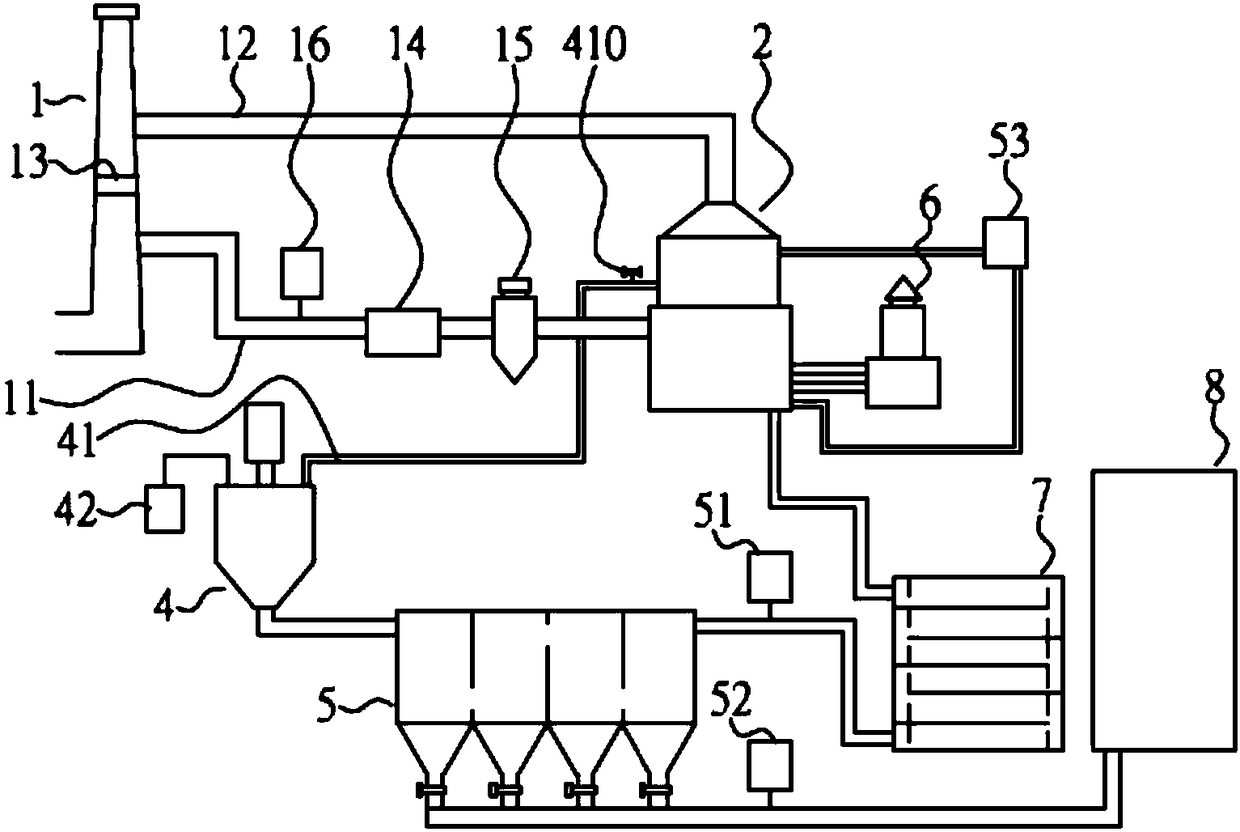

[0041] see figure 1 As shown, the present invention provides a waste gas emission treatment device, which includes a chimney pipe (1) connected to a washing unit (2) through an inlet pipe (11).

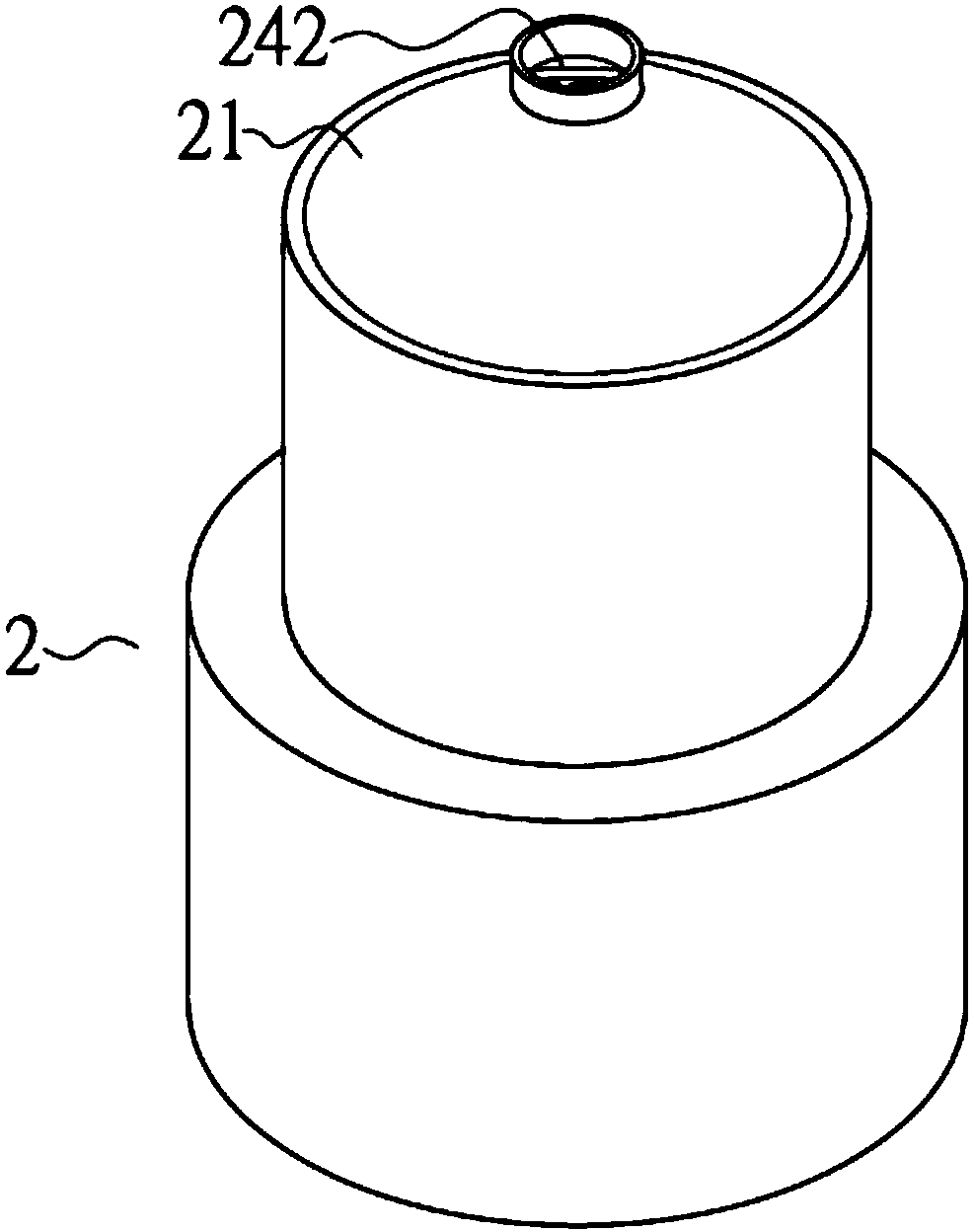

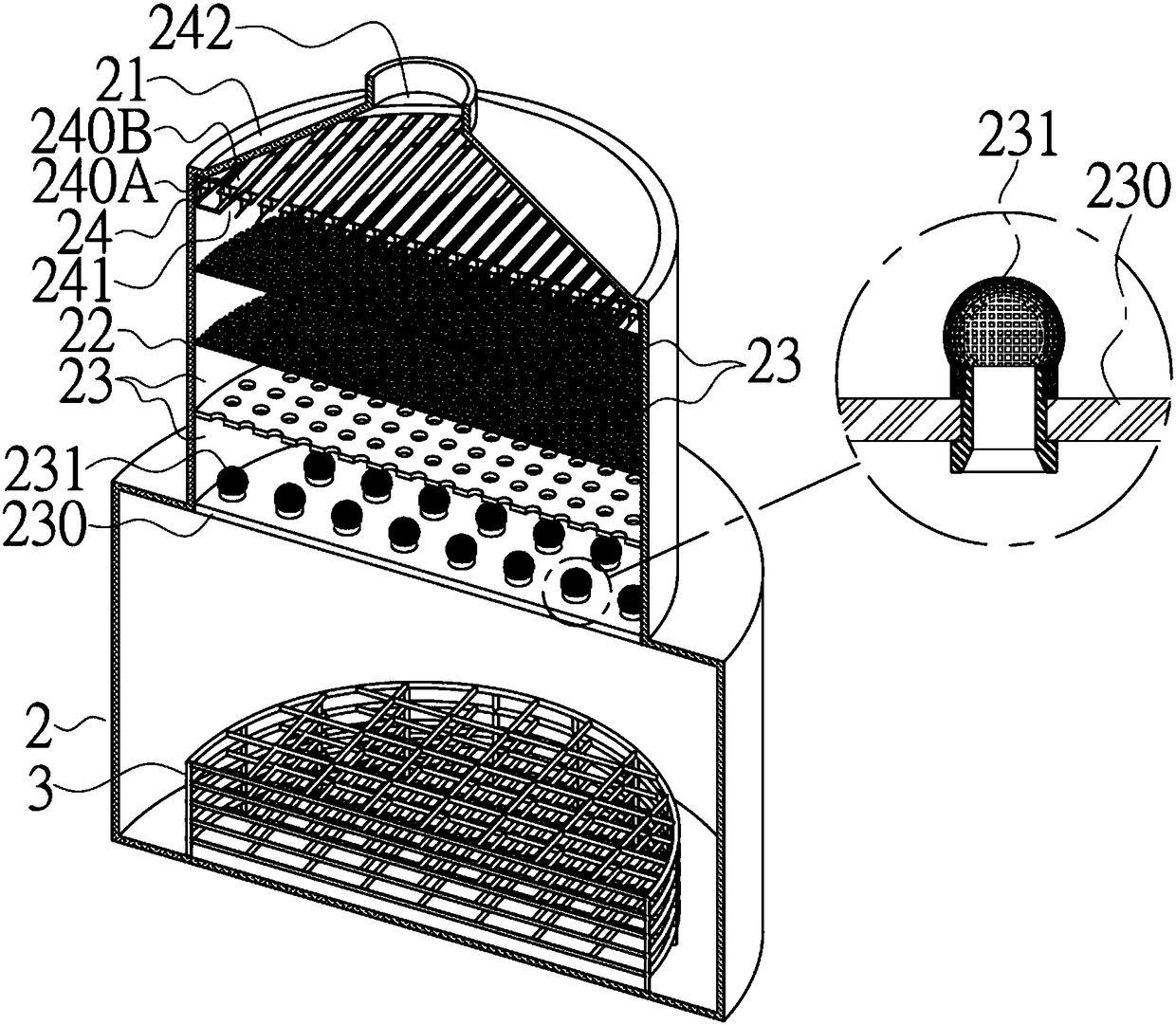

[0042] like figure 2 and image 3 Shown, this washing unit (2) comprises a cover (21), frame encircles and limits a washing chamber (22), and this washing chamber (22) is provided with multi-layer grid dish (23) from top to bottom, and this washing In the chamber (22) for containing water (such as Figure 4 shown).

[0043] see figure 2 Shown, wherein one layer of net pan (23) of multi-layer net pan (23) is made up of a plurality of spherical screens (231) that are provided with on a plate body (230) and it, and each this Below the spherical mesh screen (231) and the washing chamber (22) communicate directly or indirectly with the inlet pipe (11), and the washing chamber (22) communicates with the chimney pipe (1) through an outlet pipe (12). In one embodiment of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com