Multi-degree-of-freedom sample rod

A sample rod and degree of freedom technology, applied in the field of sample rods, can solve the problems of easy deformation of flexible wire claws, low precision, equipment damage, etc., and achieve the effect of simple and clear connection relationship, improving displacement control accuracy, and reducing manufacturing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

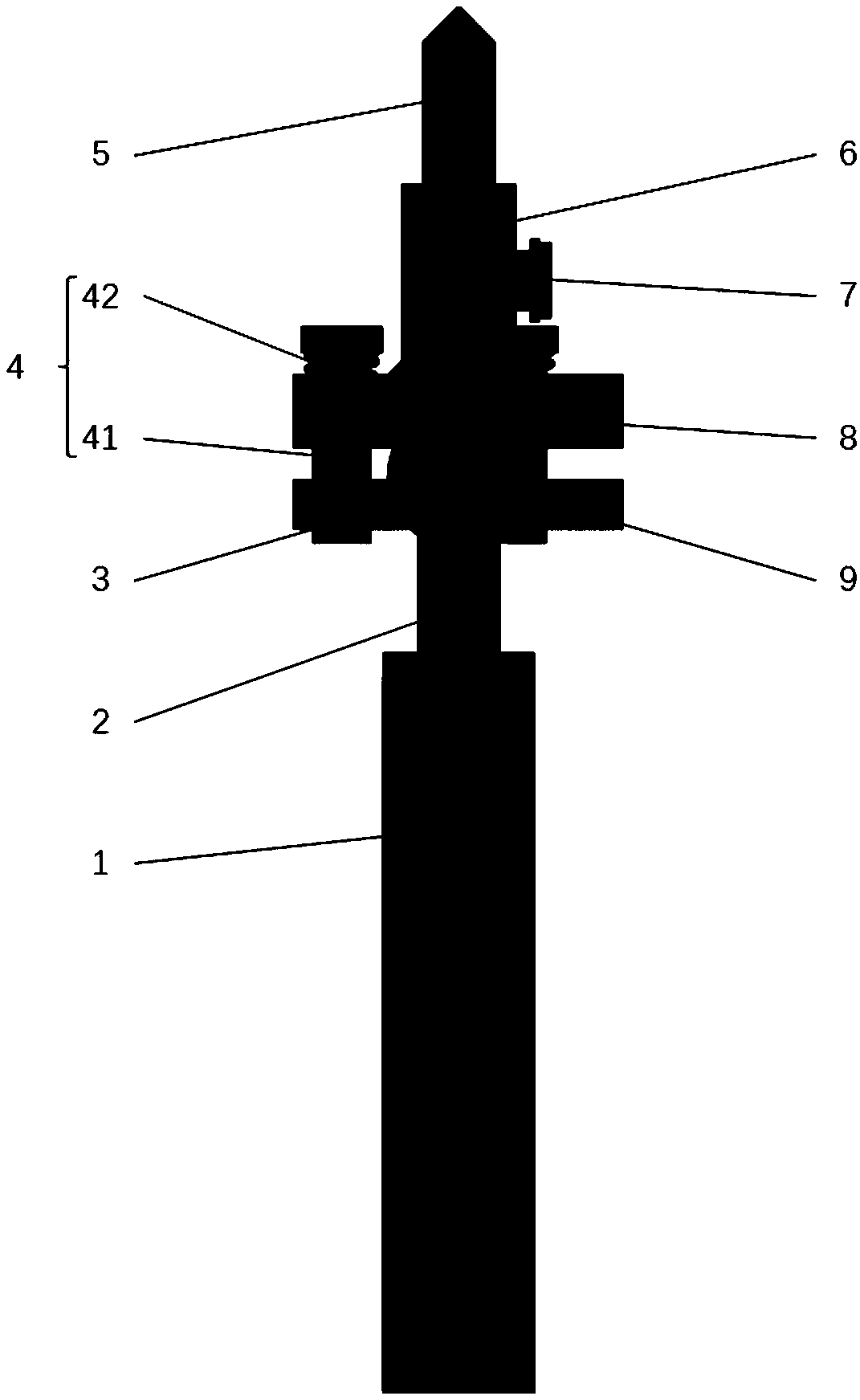

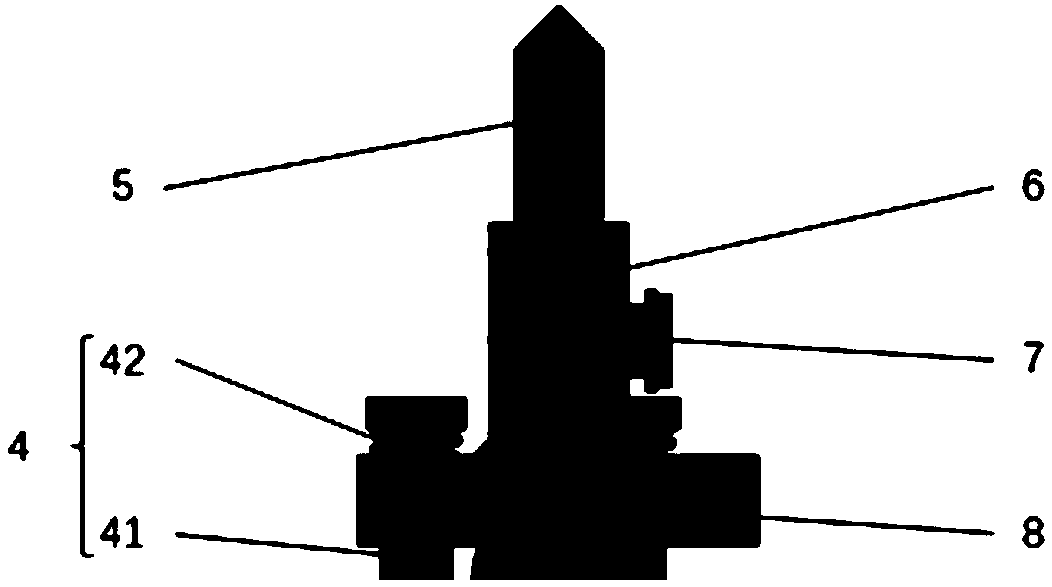

[0035] Such as figure 2 As shown, the multi-degree-of-freedom sample rod is provided with a nanopositioner on the sample rod. The nanopositioner includes a driving part 1, a joint ball 3 and a pressing part assembly. The joint ball 3 is fixed with the driving part 1. The pressing part assembly includes at least two The pressing piece and the elastic connecting component 4 , the elastic connecting component 4 connects adjacent pressing pieces, the pressing piece component embraces the joint ball 3 , and there is a pre-tightening force between the pressing piece and the joint ball 3 . For example, a piezoelectric ceramic tube is used as the drive element 1 .

[0036] Pressed piece

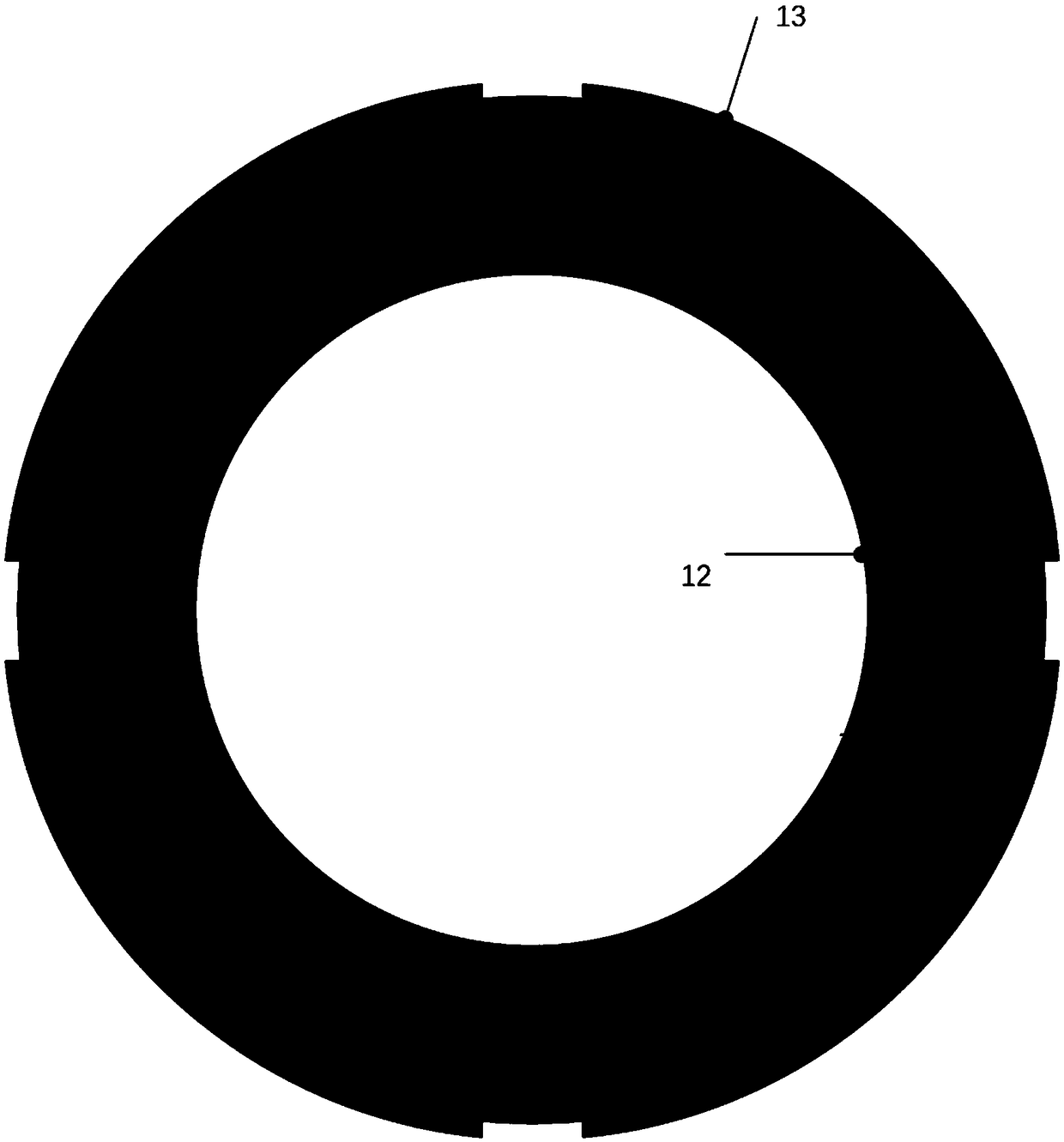

[0037] In some embodiments, each pressing piece has a concave portion 81 and a connecting portion 82 respectively, the elastic connection assembly 4 is arranged between the connecting portions 82 of adjacent pressing pieces, and the concave portions 81 of all pressing pieces are formed to cooperate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com