OLED display device and method for manufacturing OLED display device

A technology for display devices and packaging layers, which is applied in the manufacture of semiconductor/solid-state devices, organic semiconductor devices, semiconductor devices, etc., can solve the problems of poor adhesion between the CPL layer and the film packaging layer, reduce the phenomenon of film stripping, and solve the problem of easy Effects of damage and improved bending reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

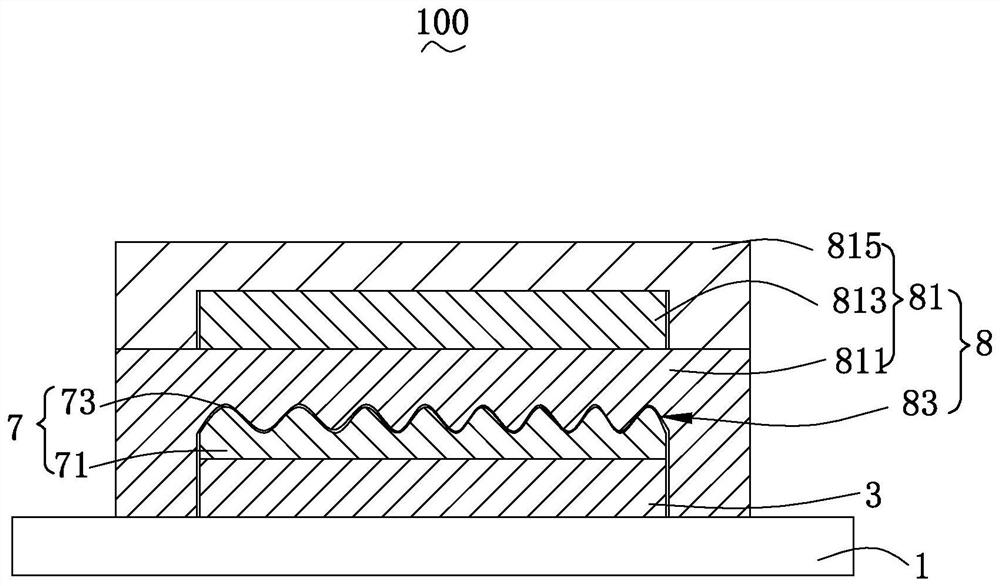

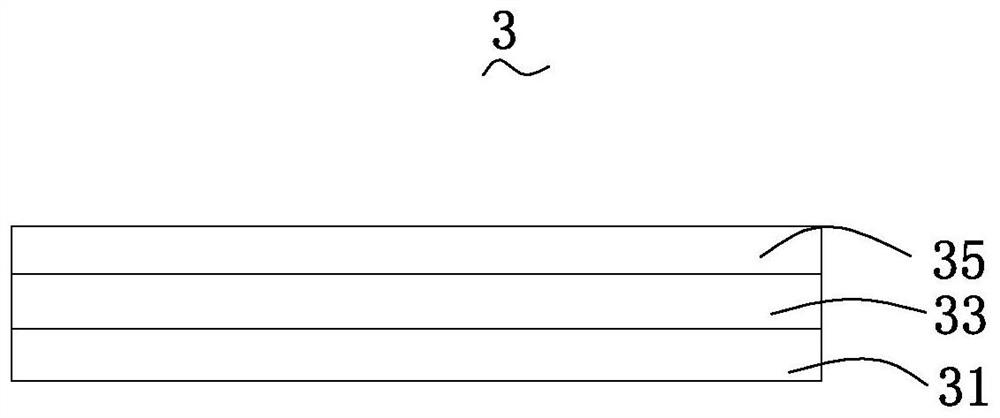

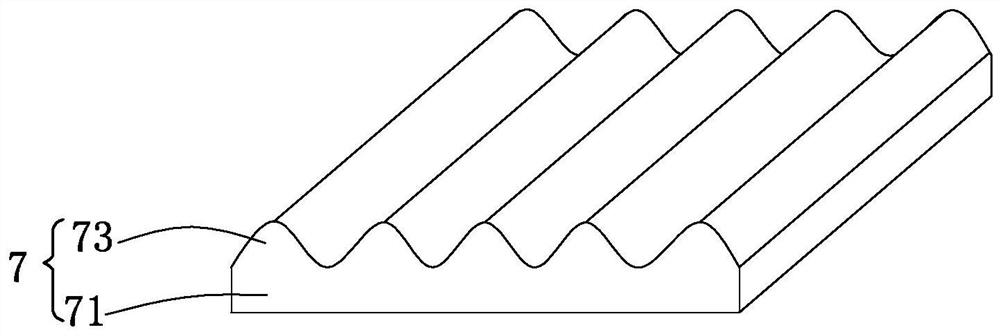

[0024] see figure 1 , a schematic structural diagram of the OLED display device of this embodiment. The OLED display device 100 provided in this embodiment includes a substrate 1 , an OLED unit 3 , an optical coupling layer 7 and an encapsulation layer 8 for encapsulating the OLED unit 3 stacked in sequence. The material of the substrate 1 is selected as flexible glass, the OLED unit 3 is prepared on the substrate 1, and serves as the light-emitting unit of the OLED display device 100, and the refractive index suitable for the optical coupling layer 7 prepared on the OLED unit 3 satisfies certain conditions, so that The light extraction rate of the OLED unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com