White plume elimination system for flue gas and method using white plume elimination system

A flue gas and whitening technology, which is applied in the field of flue gas whitening system, can solve the problems of increased energy consumption and non-compliance, and achieve the effects of reducing water content, simple structure, and improving whitening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example 1

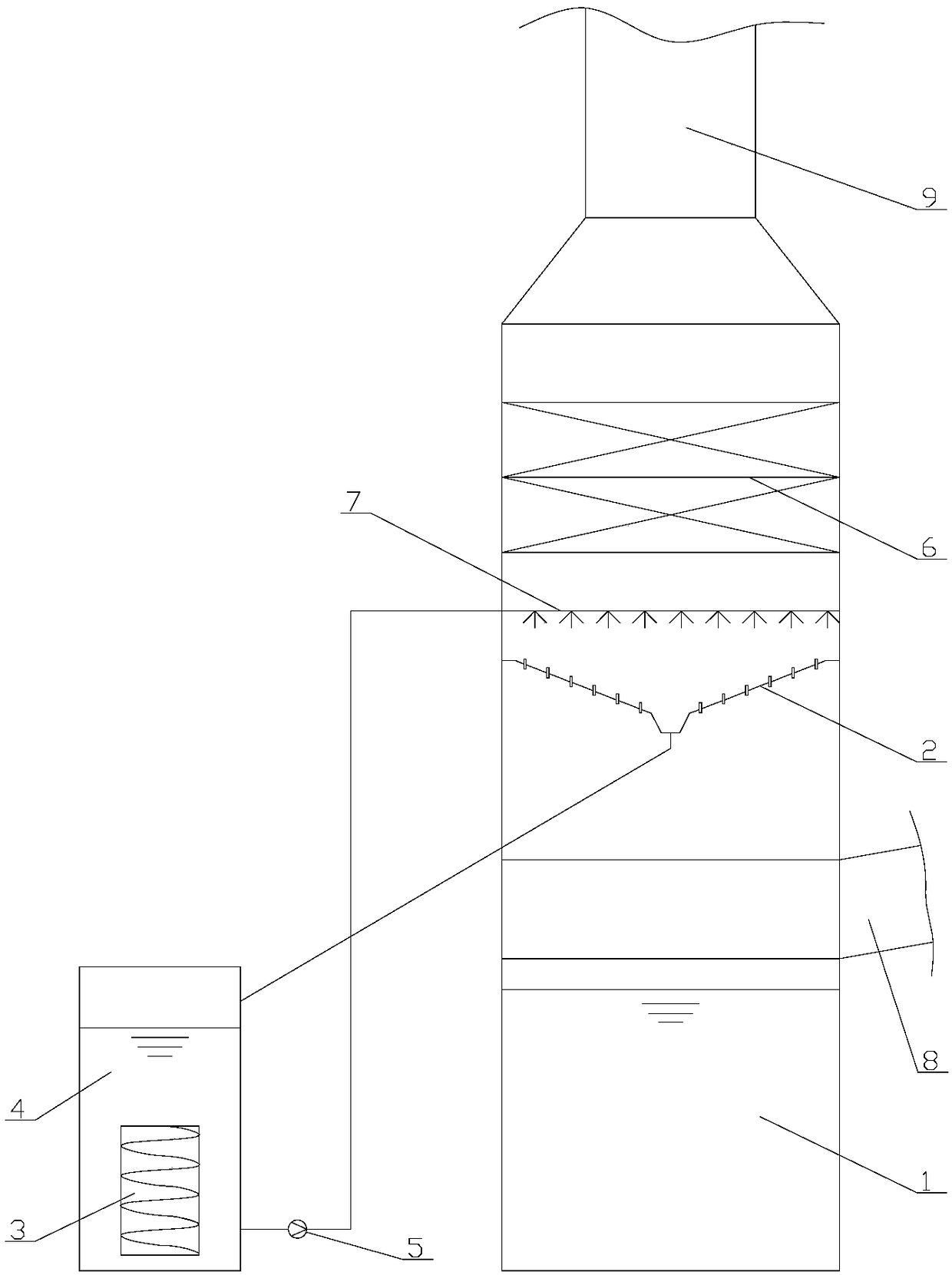

[0026] A flue gas whitening system, including a desulfurization tower 1, an immersed U-shaped tube bundle slurry cooling device 3, a circulation tank 4 and a circulation pump 5. The desulfurization tower 5 is sequentially provided with a mist eliminator 6, a spray layer from top to bottom 7 and the inverted quadrangular pyramid circular slurry collection device 2, the immersed U-shaped tube bundle slurry cooling device 3 is set in the circulating tank 4, the outlet of the circulating tank 4 is connected with the inlet of the circulating pump 5, and the outlet of the circulating pump 5 is connected to the desulfurization tower 1. The slurry inlet is connected, and the outlet of the inverted quadrangular pyramid-shaped circulating slurry collecting device 2 is connected with the inlet of the circulating tank 4. The desulfurization tower 1 is also provided with a desulfurization tower flue gas inlet 8 and a desulfurization tower flue gas outlet 9.

[0027] Use the ...

Example Embodiment

[0029] Example 2

[0030] A flue gas whitening system, including a desulfurization tower 1, an immersed U-shaped tube bundle slurry cooling device 3, a circulation tank 4 and a circulation pump 5. The desulfurization tower 5 is sequentially provided with a mist eliminator 6, a spray layer from top to bottom 7 and the inverted cone-shaped circulating slurry collecting device 2, the immersed U-shaped tube bundle slurry cooling device 3 is set in the circulating tank 4, the outlet of the circulating tank 4 is connected with the inlet of the circulating pump 5, and the outlet of the circulating pump 5 is connected with the desulfurization tower 1 The slurry inlet is connected, and the outlet of the inverted cone-shaped circulating slurry collecting device 2 is connected with the inlet of the circulating tank 4. The desulfurization tower 1 is also provided with a desulfurization tower flue gas inlet 8 and a desulfurization tower flue gas outlet 9.

[0031] Use the above-mentioned flue ...

Example Embodiment

[0033] Example 3

[0034] A flue gas whitening system, comprising a desulfurization tower 1, an immersed floating head tube type slurry cooling device 3, a circulation tank 4 and a circulation pump 5. The desulfurization tower 5 is sequentially provided with a mist eliminator 6, a spray layer from top to bottom 7 and the inverted quadrangular pyramid circular slurry collection device 2, the immersed floating head tube type slurry cooling device 3 is arranged in the circulating tank 4, the outlet of the circulating tank 4 is connected with the inlet of the circulating pump 5, and the outlet of the circulating pump 5 is connected to the desulfurization tower 1 The slurry inlet is connected, and the outlet of the inverted quadrangular pyramid-shaped circulating slurry collecting device 2 is connected with the inlet of the circulating tank 4. The desulfurization tower 1 is also provided with a desulfurization tower flue gas inlet 8 and a desulfurization tower flue gas outlet 9.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap