Material toggling sieve

A material sieve and sieve material technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems that solid materials cannot be effectively used, materials are lumped, and increase difficulty, so as to reduce processing difficulty and improve stability Sexuality, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

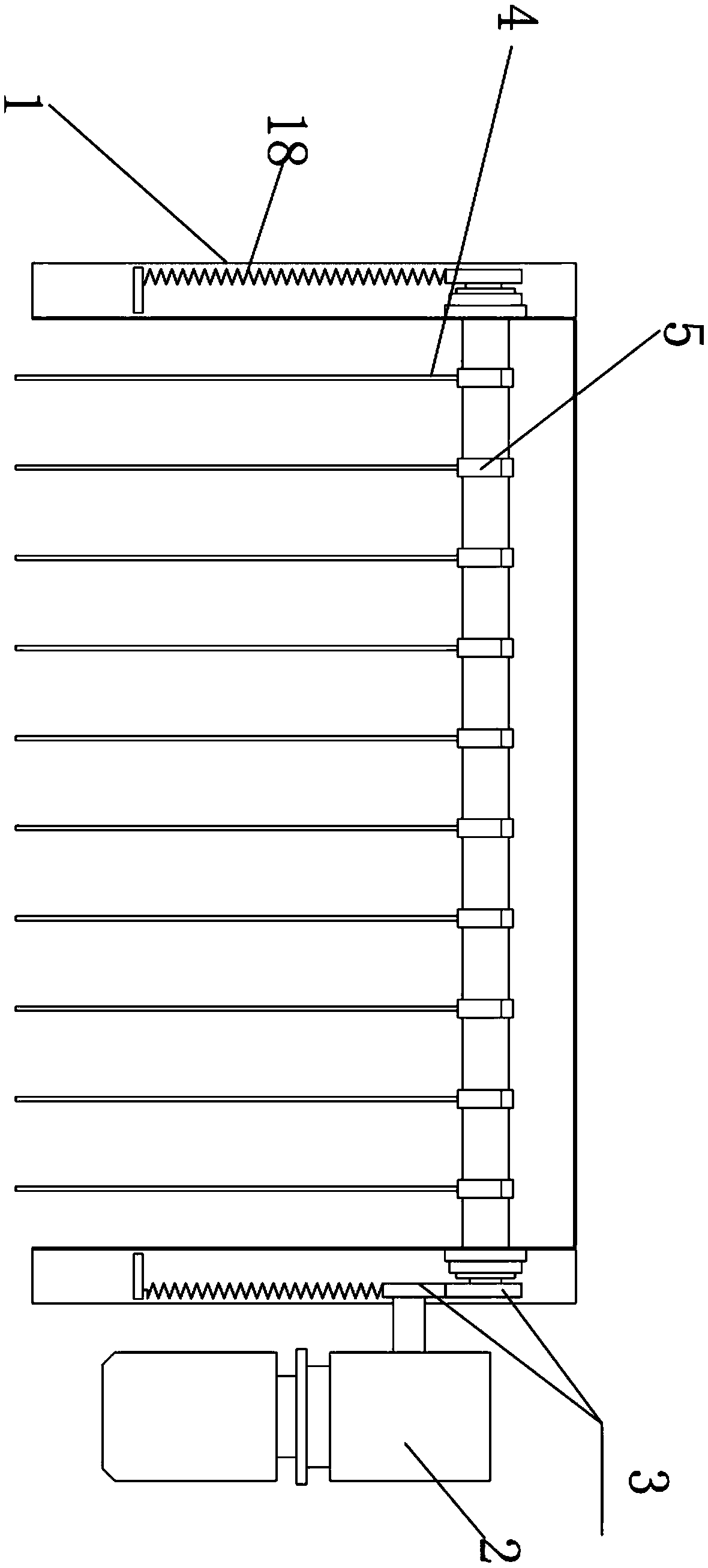

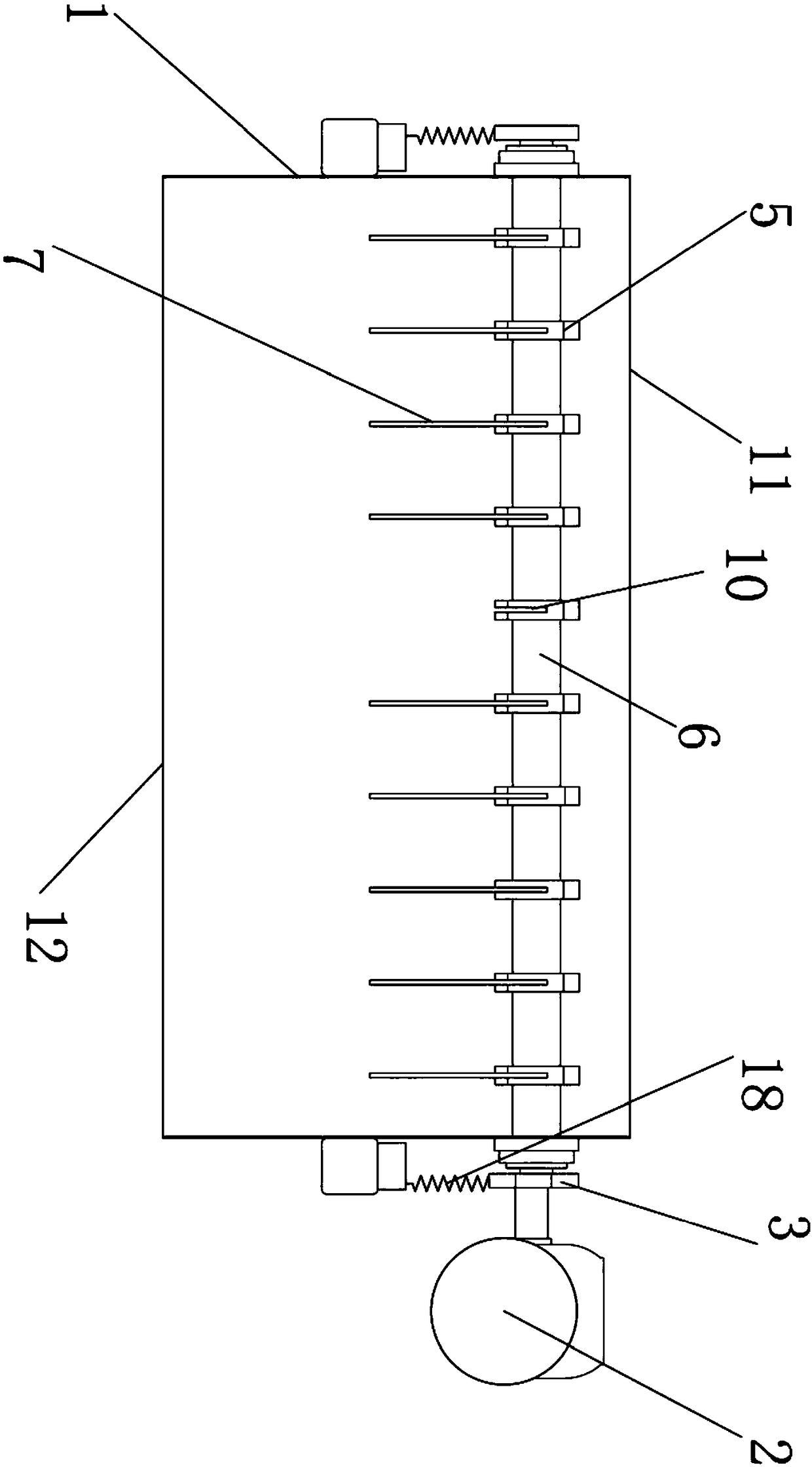

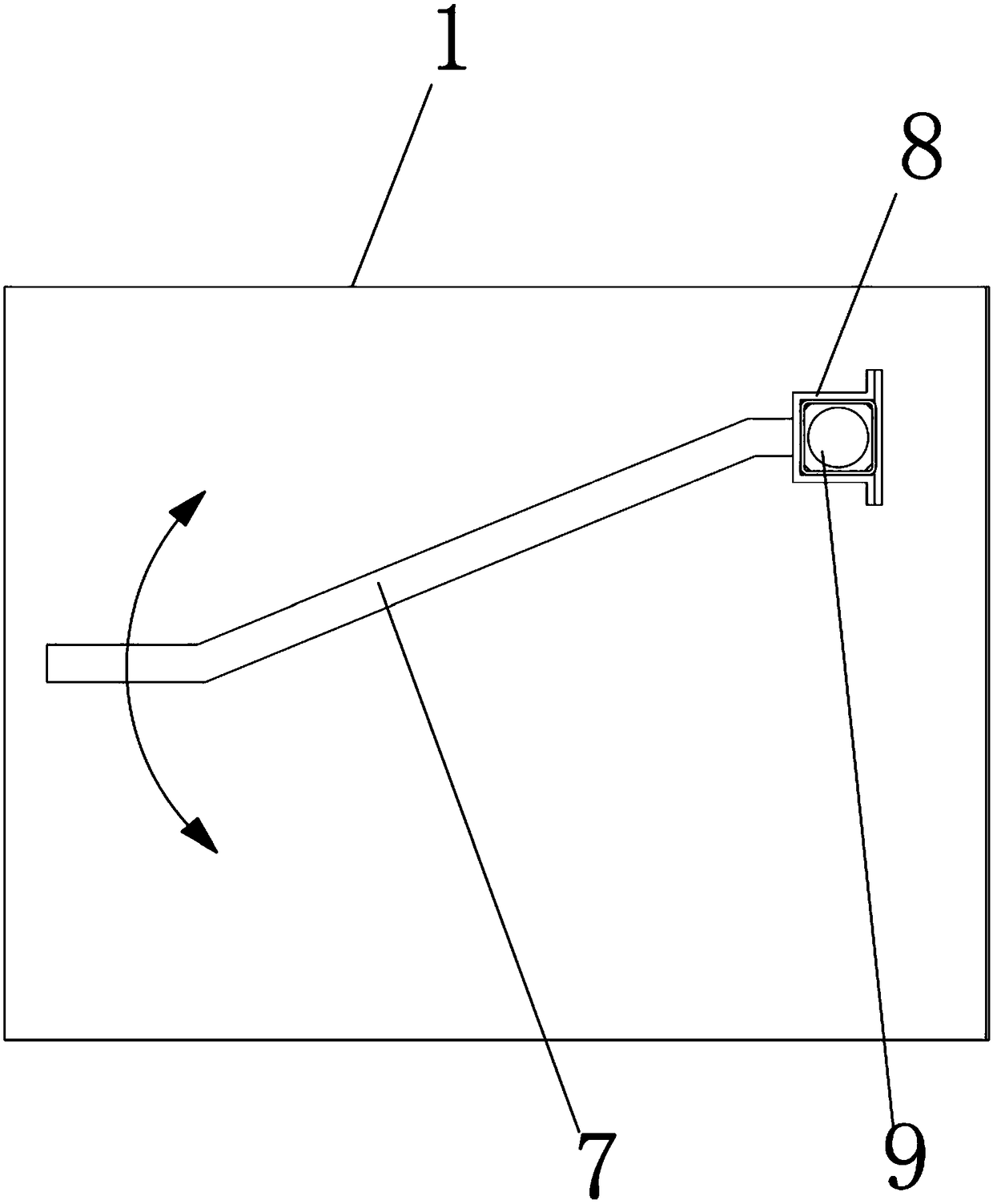

[0026] Such as Figure 1-4 As shown, the technical solution adopted by the present invention to solve the above-mentioned technical problems is: a kind of material shifting screen, comprising a body 1, a power device 2, a transmission device 3 and a material screening device 4 are arranged on the body 1, the power The device 2 is connected with the sieve device 4 through the transmission device 3, and an adjustment device 5 is arranged on the sieve device 4, and the position clearance of the sieve device 4 is adjusted by the adjustment device 5;

[0027] The sieving device 3 includes a main shaft 6 and a sieve plate 7, and the sieve plate 7 is fixedly arranged on the main shaft 6 through a joint device 5;

[0028] The adjustment device 5 includes an adjustment seat 8, and an installation hole 9 and an opening 10 are provided on the adjustment seat 8. The adjustment seat 8 is sleeved on the main shaft 6 through the installation hole 9, and the sieve plate 7 passes through the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com