Welded membrane

A technology for welding tires and positioning tires, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor welding effect and low assembly efficiency of radar brackets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

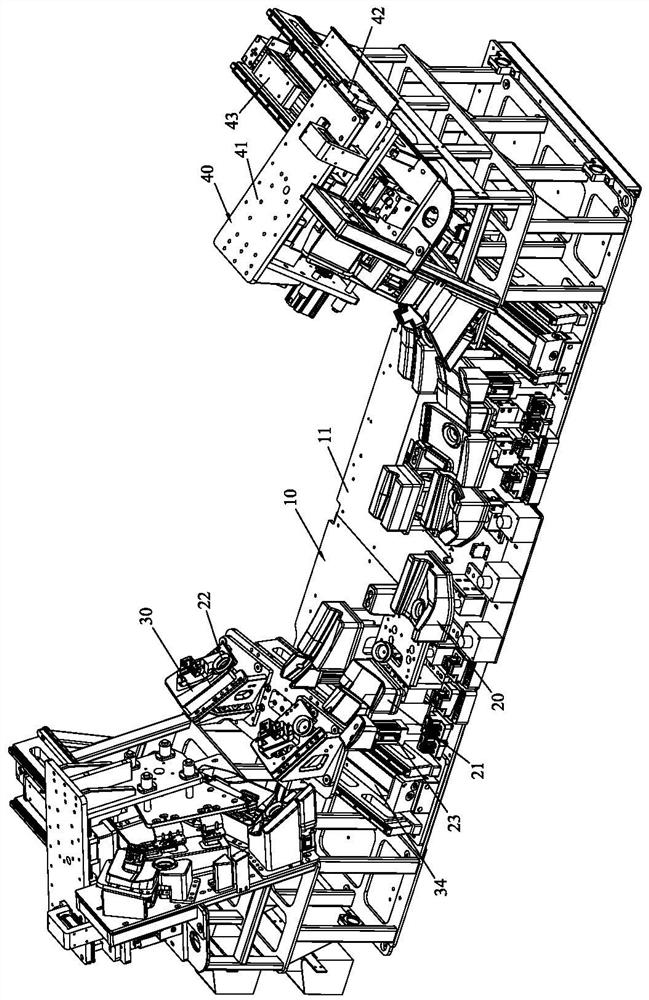

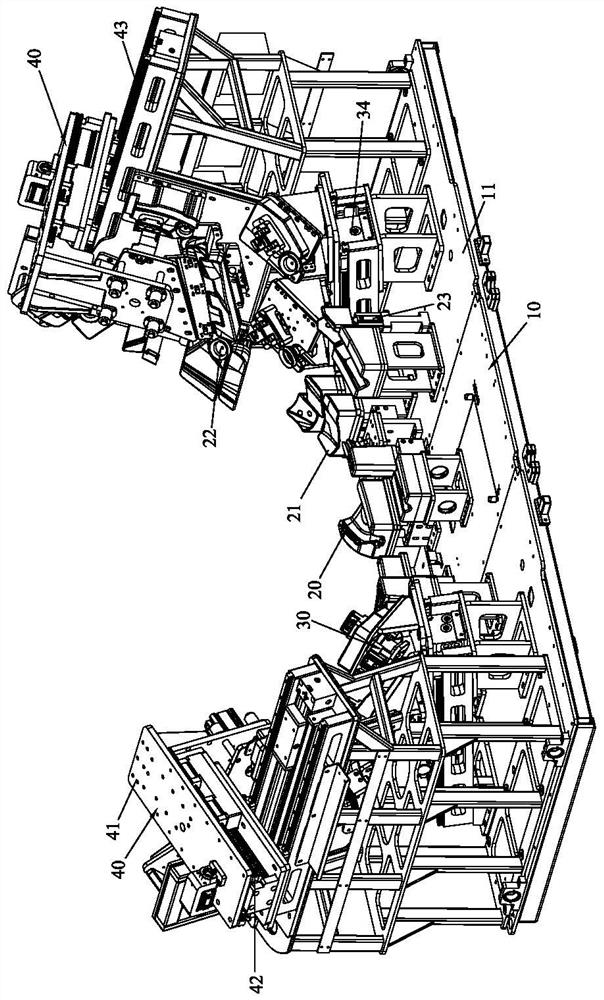

[0037] Please refer to Figure 1 to Figure 6 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a base 10 and a positioning membrane 20 .

[0038] The base 10 is arranged at the bottom of the whole device, and the base 10 provides a working plane 11 for the whole device.

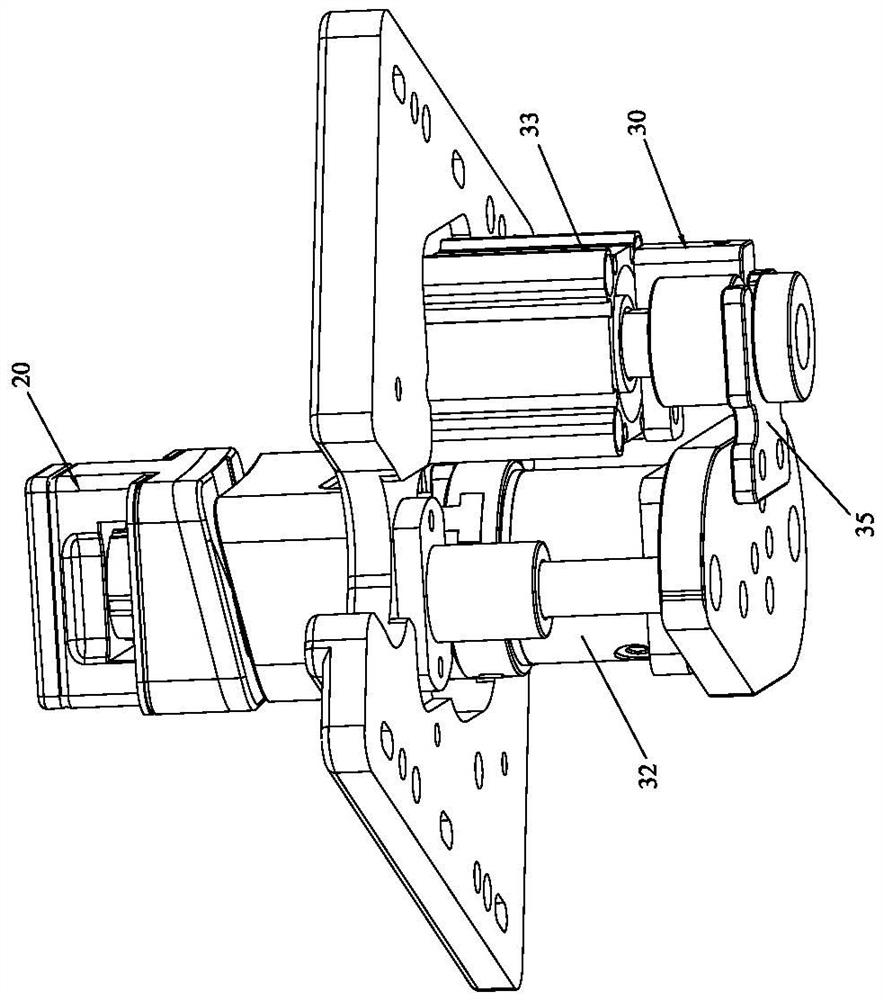

[0039] The positioning membrane 20 includes a mold cavity 21 for supporting automotive trims, a third driver 23 and a suction cup 22. The third driver 23 is a cylinder. The base 10 is provided with a plurality of positioning membranes 20, and some positioning tires are arranged. The membrane 20 is provided with a third driver 23, and the other part of the positioning membrane 20 is not provided with the third driver 23, wherein the membrane provided with the third driver 23 has the function of ejecting the product. Some of the positioning membranes 20 with ejection function are provided with a suction cup 22 in the middle, and the suction cups 22 can mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com