A method and system for dealing with ground excessive phase-splitting faults

A technology of over-phase and ground, applied in the direction of power lines, vehicle components, transportation and packaging, etc., can solve the problems of locomotive main circuit breaker tripping, burning of on-board equipment, and equalization of live electricity, so as to ensure normal operation, reduce the scope of faults, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

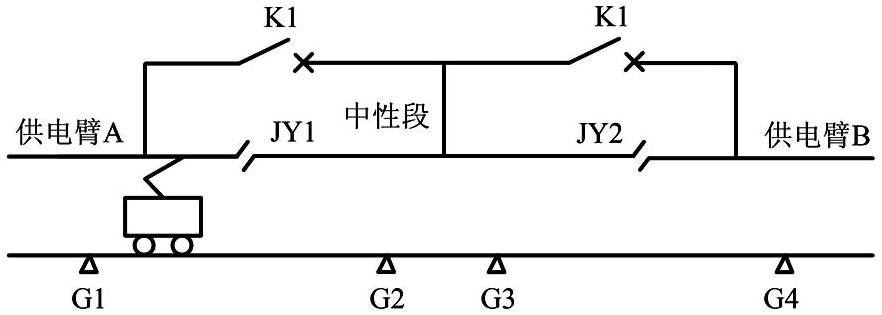

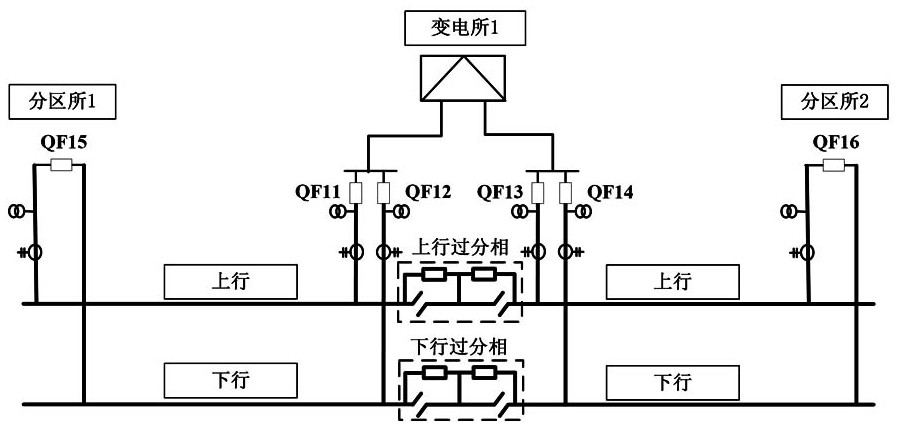

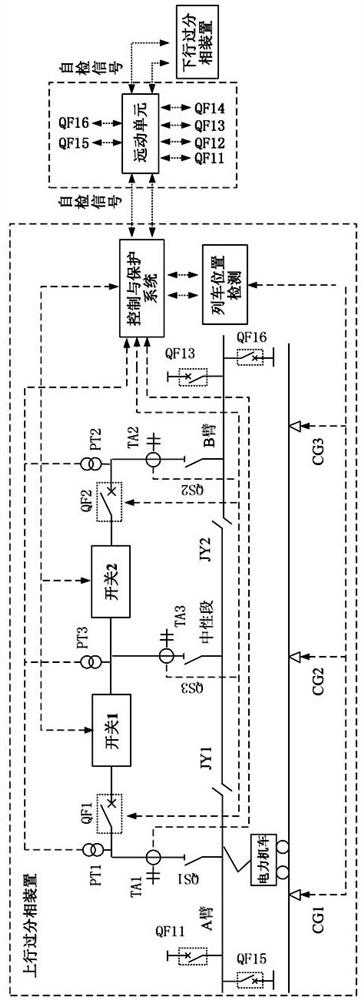

[0035] Such as figure 2 and image 3 As shown, the traction power supply network in the present invention includes uplink and downlink power supply lines. Substation feeder circuit breakers QF11 and QF13; substation feeder circuit breakers QF12 and QF14 are set between the substation and the downstream power supply line, and substation feeder parallel circuit breakers QF15 and QF16 are set between the upstream power supply line and the downstream power supply line , wherein the structure of the ground overphase device and the specific overphase method are the same as those of the prior art, such as image 3 As shown, three train position sensors CG1~CG3 are installed on the train running route to detect the train position, among which PT1, PT2, PT3 are voltage transformers, TA1, TA2, TA3 are current transformers, QF1, QF2 are branch For cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com