Steering hydraulic oil cooling device for commercial vehicle

A technology for steering hydraulic and cooling devices, which is applied to steering mechanisms, fluid steering mechanisms, power steering mechanisms, etc. It can solve problems such as poor heat dissipation effect and complex pipeline structure, and achieve good heat dissipation effect, good heat dissipation effect, and smooth flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

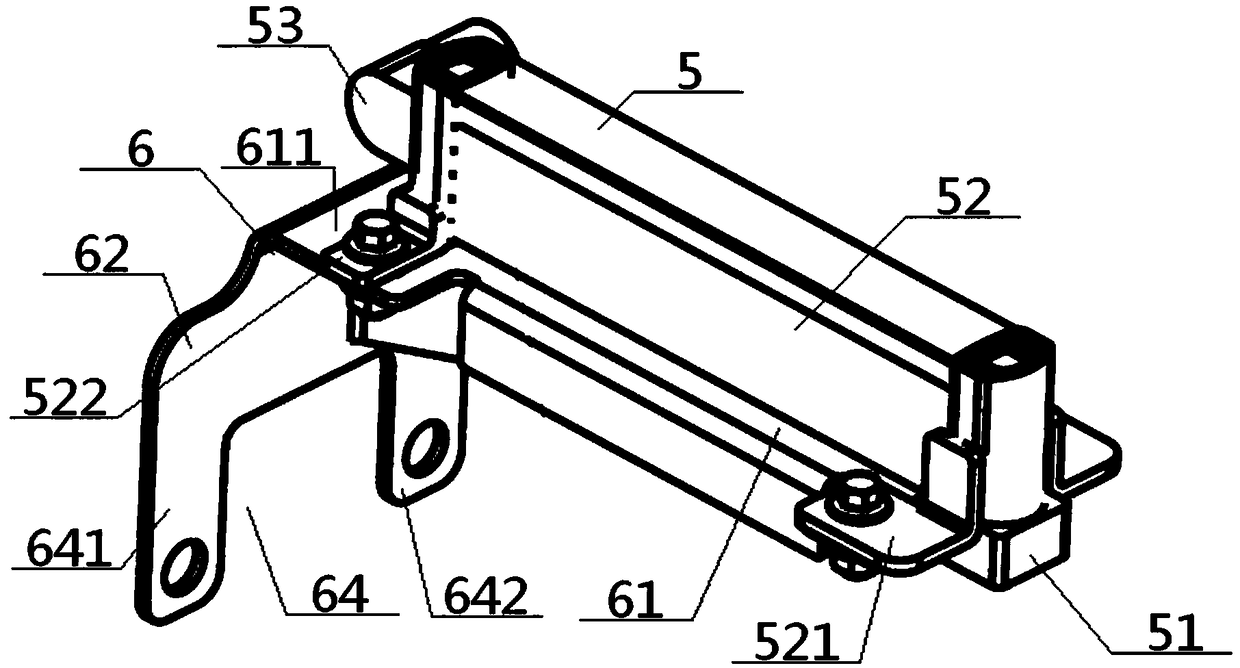

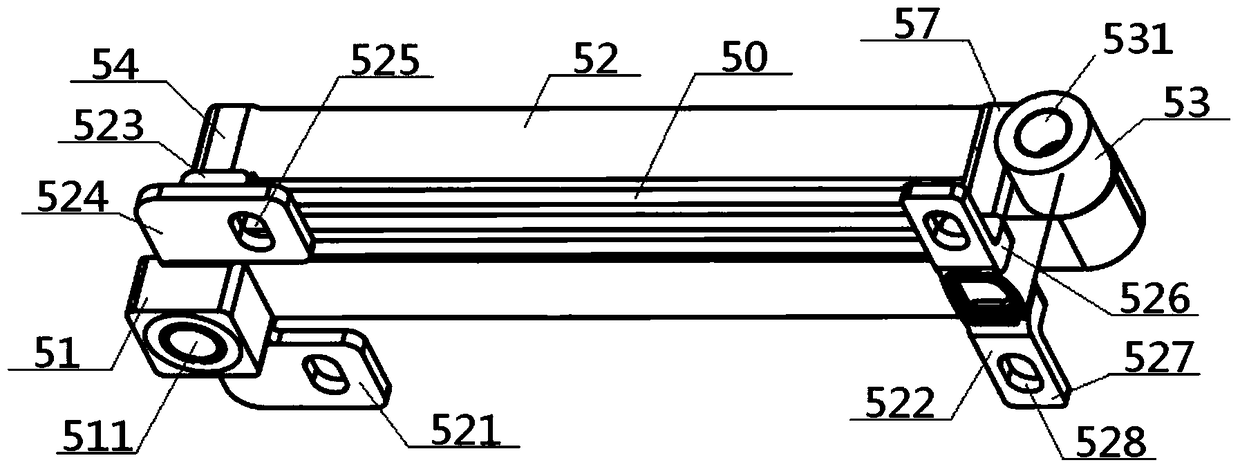

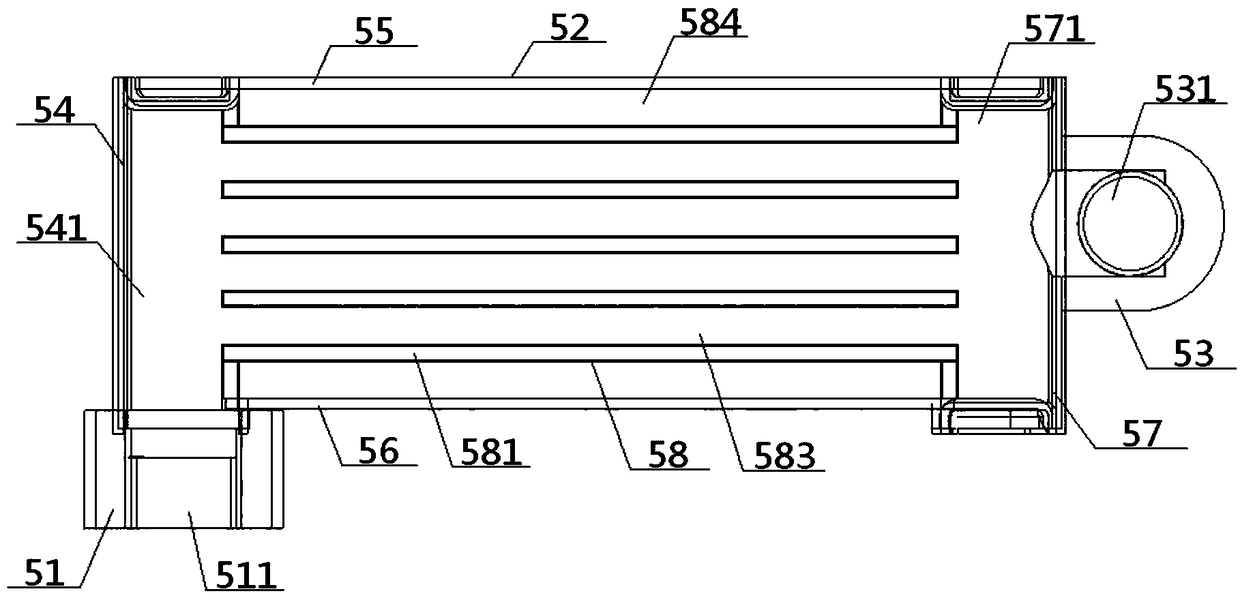

[0058] see Figure 1 to Figure 9 , a steering hydraulic oil cooling device for commercial vehicles, comprising a steering oil temperature radiator 5 and a radiator bracket 6, the steering oil temperature radiator 5 is connected to the vehicle frame 1 through the radiator bracket 6; the steering The oil temperature radiator 5 includes an oil inlet end 51, a heat dissipation body 52 and an oil outlet end 53. The heat dissipation body 52 includes an oil inlet column 54, an upper connecting plate 55, a lower connecting plate 56 and an oil outlet column 57. The oil inlet The bottom end of the column 54 is connected with the top of the oil inlet port 51, and the upper and lower ends of the inner surface of the oil inlet column 54 respectively go through the upper and lower ends of the upper connecting plate 55, the lower connecting plate 56 and the inner surface of the oil outlet column 57. The lower two ends are connected correspondingly, the outer surface of the oil outlet column ...

Embodiment 2

[0060] Basic content is the same as embodiment 1, the difference is:

[0061] A plurality of cooling fins 59 are arranged between the upper connection plate 55 and the adjacent heat dissipation layer 58, between the lower connection plate 56 and the adjacent heat dissipation layer 58, and between the adjacent heat dissipation layer 58. Two ends of the heat sink 59 are vertically connected with the upper connection plate 55 , the lower connection plate 56 or the heat dissipation layer 58 that are in contact with it.

Embodiment 3

[0063] Basic content is the same as embodiment 1, the difference is:

[0064] The front and rear sides of the outer surface of the oil inlet column 54 near the oil inlet end 51 are respectively connected to an oil inlet bracket 521, and the front and rear sides of the outer surface of the oil outlet column 57 near its bottom end are respectively connected to each other. The rear side is connected with an oil outlet bracket 522 respectively, and the oil inlet bracket 521 and the oil outlet bracket 522 are both connected with the vehicle frame 1 through the radiator bracket 6 .

[0065] Preferably, the oil inlet bracket 521 includes an oil inlet vertical plate 523 and an oil inlet horizontal plate 524, the inner surface of the oil inlet vertical plate 523 is connected with the outer surface of the oil inlet column 54, and the bottom end of the oil inlet vertical plate 523 is connected with the oil inlet horizontal plate 524. One end of the plate 524 is vertically connected, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com