Output hydraulic oil cooling steering gear set system

A technology of steering gear and hydraulic oil, which is applied to fluid steering mechanism, fluid pressure actuation system components, mechanical equipment, etc. It can solve the problems of poor heat dissipation, complex pipeline structure, and poor installation position, etc., to achieve good heat dissipation, The pipeline structure is simple and the installation difficulty is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

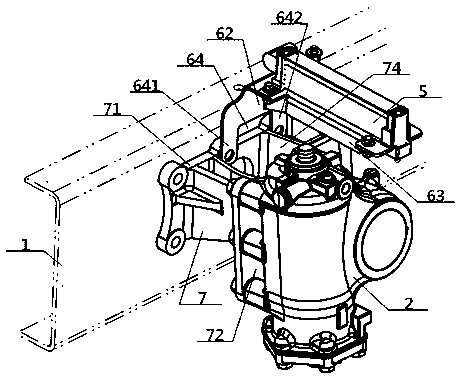

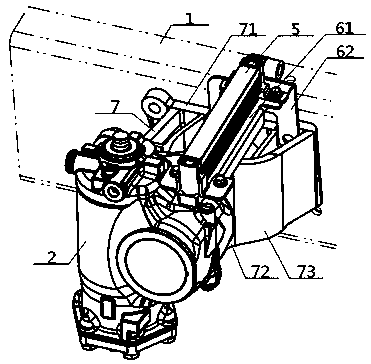

[0058] see Figure 1 to Figure 10 , an output hydraulic oil cooling type steering gear assembly system, including a steering gear assembly 2 and a steering oil temperature radiator 5, and the steering gear assembly 2 is connected to a steering gear bracket 7; the steering oil temperature radiator 5 The bottom is connected with the steering gear bracket 7 through the radiator bracket 6, the steering gear bracket 7 is connected with the vehicle frame 1, the oil outlet of the steering gear assembly 2 communicates with the oil inlet of the steering oil temperature radiator 5, and the steering oil temperature The oil outlet of radiator 5 communicates with the oil inlet of steering oil tank 3 .

Embodiment 2

[0060] Basic content is the same as embodiment 1, the difference is:

[0061] The oil outlet of steering gear assembly 2 communicates with the oil inlet of steering oil temperature radiator 5 through No. 3 front pipeline 83, and the oil outlet of steering oil temperature radiator 5 communicates with steering oil tank through No. 3 rear pipeline 84. The oil inlets of No. 3 are connected, and No. 3 front pipeline 83 and No. 3 rear pipeline 84 all turn to low-pressure pipelines. Preferably, No. 3 front pipeline 83 includes No. 3 front 1 pipeline 831 and No. 3 front 2 pipeline 832 connected to each other. The oil outlet of the steering gear assembly 2 passes through No. 3 front 1 pipeline 831 and No. The rear of the first two pipelines 832 communicates with the oil inlet of the steering oil temperature radiator 5; the No. 3 rear pipeline 84 includes the No. 3 rear 1 pipeline 841 and the No. 3 rear 2 pipeline 842 connected to each other. The oil outlet of the oil temperature radia...

Embodiment 3

[0063] Basic content is the same as embodiment 1, the difference is:

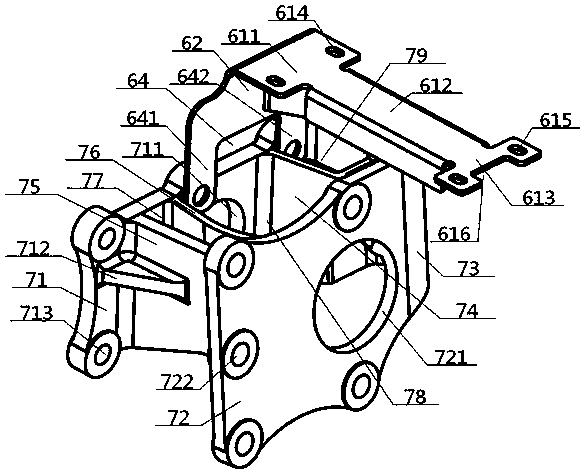

[0064] The radiator bracket 6 includes a radiator fixing plate 61, a bracket fixing plate 62 and a slanting support rib 63. One end of the bracket fixing plate 62 is provided with a bracket gap 64 opening downward and brackets on both sides of the bracket gap 64. Leg one board 641, support leg two boards 642, support leg one board 641, support leg two boards 642 are connected with vehicle frame 1 through steering gear support 7, and the other end of bracket fixing plate 62 is perpendicular to the end of radiator fixing plate 61 Connected, the top surface of the other end of the radiator fixing plate 61 is connected with the bottom of the steering oil temperature radiator 5 through the oil inlet bracket 521, the radiator fixing plate 61 is near the bracket fixing plate 62, and the junction of the radiator fixing plate 61 The top surface of the position is connected to the bottom of the steering oil temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com